The focus on enhancing reliability and efficiency of the power grid has led to implementation of the smart grid concept. This concept is based on the deployment of automation — namely advanced distribution automation (ADA) applications — and control technologies relying on the availability of characteristic parameters acquired from the network itself.

When comparing the smart grid to the traditional grid, two main differences exist: the presence of distributed energy resources (DERs), including renewables, and the integration of a significant number of ADA applications. Based on these applications, the grid automation process is benefitting from the information provided by real-time monitoring of the grid at an increased number of overhead and underground distribution nodes.

Smart Distribution

A more dynamic smart medium-voltage distribution network offers higher reliability, efficiency and greater remote-control flexibility through automated devices — namely reclosers, voltage regulators, load switches and capacitor banks — equipped with intelligent electronic devices (IEDs), such as controllers, relays and sensors, representing a new generation of more accurate and better performing transducers.

The deployment of these automation and control technologies that rely on the availability of various parameters such as voltage and current in certain nodes of the network has led to an improvement in the performance distribution networks of some utilities including Hydro-Québec.

In the utility’s journey to implement the smart grid, distribution automation and associated technologies have lagged that of generation and transmission. Reasons for this technology implementation delay include the large number of distribution network components, their low cost and the lack of affordable widespread telecommunications infrastructure.

The smart grid generally is portrayed as a large deployment of smart meters and their telecommunications network. Advanced metering infrastructure has made possible the transfer of a huge quantity of data, referred to as big data. Thanks to new analytics platforms, this data is stored in relational databases and post-treated by complex algorithms, with the results made available to ADA applications.

The proliferation of ADA applications in smart grids is the result of reliable, accurate data acquisition at an increased number of monitoring nodes located in substations along the feeder, at the point of connection of DERs (including storage) and at the customer’s point of common coupling.

At any monitoring node, there is a measurement chain that normally includes sensors, intelligent electronic devices (IEDs) and communications links. Typically, a monitoring node should support and can provide — remotely, partially or totally — the following list of system parameters classified in these categories:

• Power measurements, including volts, amperes, watts, volt-ampere-reactive (VAr), volt-ampere (VA) and power factor

• Power-quality measurements, including sags and swells, voltage and current harmonics, percent of total harmonic distortion and total demand distortion

• Environmental measurements, including temperature, humidity, water level, gas presence and concentration.

Overhead Monitoring

A review of medium-voltage distribution network monitoring systems confirms a more advanced stage of deployment and operation of the overhead line monitoring in comparison with the underground cable monitoring systems. This is because of the larger geographical areas supplied by overhead networks, inherent inferior fault performance and availability of superior communications systems.

Utilities now are exploring possibilities to leverage the monitoring potential of IEDs, such as remote terminal units, controllers, relays and meters/advanced metering infrastructure by transferring the data acquisition to the distribution network control center. The monitoring of overhead distribution networks has been subject to continuous evolution, and a range of stand-alone line-type intelligent sensors is commercially available.

The stand-alone line-type sensor is a combination of a sensor, IED and communications interface (wireless) in the same body, which can be easily installed on medium-voltage overhead line conductors using a hot stick (a common live-line procedure). The installation can be permanent or temporary, and the intelligent sensor can be removed easily and installed again at a different location where the utility needs to monitor its network. Equipped with radio-frequency or cellular communications capabilities, these line monitors can connect to existing communications networks at almost any new location. Before integrating more advanced technology solutions for overhead grid monitoring, some utilities may decide to install stand-alone line-type sensors temporarily for a transition period.

A new concept known as a universal controller is a device capable of successfully replacing IEDs, such as remote terminal units, controllers and relays, which simplifies and improves network operation control and maintenance. A universal controller should be able to operate and control any type of major distribution equipment as well as measure voltage and current magnitude and phase angle with standardized accuracy while also detecting and recording (by waveform capture) power-quality disturbances affecting the grid.

The latest universal controllers are capable of successfully replacing the previous generations of IEDs, which will simplify and improve network operation, control and maintenance.

Underground Monitoring

In the past, non-economical communications technologies limited the integration of underground smart applications, and only a few utilities have opted to deploy high-quality fiber-optic-based communications networks because they are expensive to install and maintain.

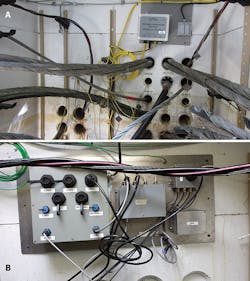

Underground cable networks include medium-voltage/low-voltage substations, cable chambers or manholes, vaults and padmounted cabinets. The environment within a cable chamber can be quite challenging in terms of available options for the power supply for measurement equipment. This challenge is compounded by the need to provide a system solution that can measure electrical and environmental parameters in real time and with sufficiently high accuracy for power-quality measurements and network diagnostic applications while minimizing the power supply requirements. From the different systems explored, the monitoring system that emerged as a viable solution is under evaluation and testing at Hydro-Québec’s Research Institute (IREQ).

Sensing and Communicating

The architecture of the proposed underground sensing and communicating infrastructure (USCI) consists of the following hardware modules:

• Power harvester module (PHM), including the magnetic core assembly (MCA) and power regulating module (PRM) with power storage options.

• Rogowski coils (with concentric sensor holder mechanism)

• Current-sensing module (CSM)

• Voltage-sensing module (VSM)

• Environmental-sensing module (ESM)

• Sensor analytics unit (SAU)

• Wireless communications gateway (WCG).

The system also includes a software module that facilitates user access to the monitored and recorded data as well as permits remote system configuration and visualization of recorded data.

This underground sensing and communications system was installed by IREQ in two cable chambers in late 2015. Measured currents and environmental data (temperature, salinity, humidity, water level, carbon monoxide, hydrogen sulfide and methane) have been monitored on an ongoing basis.

The main system components and their functions are as follows:

• The function of the power harvester module — which has two main assemblies, the MCA and PRM — is to harvest power from a medium-voltage power distribution cable. The MCA uses a single or dual inductive coupling mechanism, depending on line load, to supply power to the electronic system. Construction of the MCA enables it to be installed around a medium-voltage cable in cable chambers, vaults or padmounted cabinets, for example. The PRM features built-in protection against excessive line-fault currents and comprises a voltage-limiting discharge device across the power supply as well as a local fuse to protect the power-discharge device. This module is the front end that regulates and modularizes the power intake from the MCA to providing 12/24 V from the PHU to the SAU. The SAU also can be supplied from the 120/240-V outlet.

• The CSM is equipped with four channels of concurrent analog data (three phase and neutral). The function of the CSM is to monitor data from the sensors. The data is aggregated, filtered, time synchronized, time stamped, GPS located, analyzed, encrypted and communicated from the sensor analytics unit to the WCG. Higher accuracy readings from the medium-voltage cables are obtained by Rogowski coils installed on adjustable concentric holders or from sensors (Rogowski coils) embedded in smart accessories, such as sensing dead breaks or terminations.

• The VSM is equipped with four channels of concurrent analog data (three phase and neutral). In vaults, cable chambers and dead-front padmounted cabinets, voltage readings for the VSM can be obtained through sensored accessories such as splices, terminations and dead breaks, benefiting from measurement features such as integrated voltage and current transducers.

• The ESM is designed to assess the local environment, and if needed, additional units can be added. It samples data from various environmental-type sensors with different measuring functions such as temperature, humidity, water level, salinity and gases.

• The SAU is a powerful universal controller that enables monitoring various electrical and environmental parameters in real time. The SAU prototype is designed to accommodate 12 analog channels from the CSM and VSM as well as eight digital channels from the ESM. Local analytics reporting by exception is performed in the SAU with signals from the CSM, VSM and ESM. Only 6.5 W are required for the sensing and communication system to operate in transmission mode, the worst-case scenario.

Currently, for technology validation and testing at IREQ, highly precise time-stamped GPS data is collected live through a website. However, in the future, this system can be interfaced with the utility network system (using DNP3 or IEC 61850 communications protocols). This monitoring system enables real-time configuration of utility-selected parameters and is flexible to permit future expansion.

• The WCG is embedded (flush mounted) in the center of the cable chamber cover. Its main elements include a GPS and wireless cellular radio. A dual-band antenna also is integrated into the molded housing of the WCG. The WCG has been designed and built using thermoplastic materials and coatings capable of withstanding harsh mechanical and environmental conditions.

• A user-friendly web interface has been developed to enable users to monitor recorded data remotely with customized options such as frequency of measurements intervals, severity of events color coding and equipment status.

Future Developments

A new and improved higher-efficiency power harvester module is under development. The new design is optimized to supply power based on a minimal charging load current. This device is a component of the smart power management system, which enables optimized duty-cycle reporting and ensures system functionality in the event of power loss.

The implementation of the smart grid concept has been quantified in the deployment of ADA applications. The trend is to have as many monitoring nodes as possible with limited cost and use state estimation for nodes without monitoring. A continuous technology development process and changes in the monitoring approach foster data acquisition from the distribution network and its treatment using complex algorithms at the analytic platforms level. Currently, more efficient and accurate monitoring is possible because of superior performing sensors and IEDs.

Distribution overhead line monitoring sees the introduction of line-type monitors and intelligent devices covering data acquisition, analysis and transfer to the distribution network control system center and implicitly to ADA applications.

Underground cable monitoring, which was significantly lagging, is reinvigorated with the help of new developments such as the sensing and communicating system, which can be implemented with minimal infrastructure changes to the underground cable network. Existing manhole covers can be easily modified to accommodate the WCG without requiring expensive structural changes. The system is flexible and expandable; the architecture is modular and, thus, can be scaled up or down. This system is designed with a high-computational, low-power chipset as well as with secure wireless communications enabling real-time GPS synchronized data with high bandwidth and low latency to be transmitted aboveground.

This technology addresses both present and future key utility challenges such as condition monitoring for electrical and environmental events, distributed energy balancing, grid optimization and efficiency, safety and security. The system also addresses utility cable chamber and manhole safety access by enabling the utility to monitor a hazardous environment, identifying potential safety risks such as gases or water presence before entering the manhole. Gas infiltration through the underground cable network into cable chambers and connecting ducts represents a high risk in inner-city, densely populated areas. Such a risk can be prevented by continuous monitoring of the gas level and, therefore, enhance public safety as well as utility safety.

This system also improves maintenance productivity and efficiency by providing useful real-time environmental information that enables the utility to schedule access accurately and take the next course of action accordingly.

Acknowledgment

The author wishes to acknowledge the support and assistance provided by Ernie Rodriguez of 3M Co. (USA) and George Fofeldea of 3M Co. (Canada) in the preparation of this article. Please note the prototype systems presently under evaluation at IREQ were provided by 3M Co., and the tests and evaluation have been performed by researchers from IREQ. ♦

Francisc Zavoda graduated from Bucharest Polytechnic Institute and was awarded a MSEE degree from École Polytechnique de Montréal. Following graduation, he worked with ISPE Bucharest and Siemens Canada. In 1995, he joined Hydro-Quebec’s Research Institute (IREQ). Currently, he is responsible for several projects related to power quality, the integration of sensors and intelligent electronic devices (IEDs) in smart grid and smart distribution applications, including the development of the novel concept of a universal controller for major distribution equipment.

Check out the March 2018 issue for more articles, news and commentary.

About the Author

Francisc Zavoda

Francisc Zavoda graduated from Bucharest Polytechnic Institute and was awarded a MSEE degree from École Polytechnique de Montréal. He worked for ISPE Bucharest and Siemens-Canada prior to joining the Institut de recherche d’Hydro-Québec (IREQ) in 1995. Currently, he is a senior research engineer responsible for projects related to power quality, integration of sensors and intelligent electronic devices, and smart distribution. Zavoda was the convenor of CIGRE/CIRED JWG C4.24 and is the chair of IEEE TF-P1564 and IEEE WG-P2681.