CVR Is Here to Stay

Conservation voltage reduction (CVR) enables electric distribution utilities to achieve a significant reduction in energy and peak demand at little or no cost, and without impacting customers through load shedding or equipment investments. Advantages of CVR include peak shaving, energy conservation, potential lowering of greenhouse gases and mitigation of distributed generation (DG) voltage impacts.

Utilities of all types and sizes, ranging from small- to medium-sized distribution co-ops and municipals, to large investor-owned utilities can benefit from CVR. Pee Dee Electric Cooperative (PDEC) has a history of using CVR to reduce peak demand costs. The co-op has automated its CVR process with converted water heater switches to lower and reset the regulators automatically for peak demand reduction.

What Is CVR?

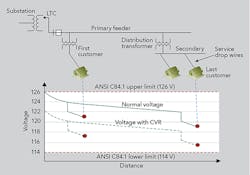

CVR is the practice of intentionally lowering the voltage on primary distribution circuits to maintain voltages on the secondary side to be in the lower portion of the acceptable voltage range defined by the American National Standards Institute (ANSI) standards. Electric distribution utilities traditionally have operated in the upper portion of the acceptable voltage range. This ensures the voltage will not temporarily dip below the minimum level during heavy load conditions when the maximum drops occur and during out-of-normal conditions when voltage sags — caused by short circuits —

occur on the grid.

The choice of operating the electric distribution lines at the higher end of the acceptable voltage range has enabled distribution utilities to deliver power at the lowest cost possible, because operating in the lower portion of the range would require continuous monitoring facilities at feeder extremities and other strategic locations to warn the distribution operator when the voltage is approaching the lower limit.

Most utilities have not been concerned about exceeding the upper limit of the voltage range at points outside the substation. The substation bus has always been the high-voltage point on the feeder, with the voltage dropping as it gets farther from the substation, as a result of unidirectional

power flow from the substation to the load.

The growing presence of DG resources has raised the possibility of reverse power flow that produces higher voltages farther from the substation. This new concern about exceeding the high-voltage limit on feeders with a high penetration of DG connected is another emerging reason for utilities to consider lowering the voltage on the electric distribution system.

Voltage reduction is not a new concept. Many electric utilities and their associated grid management authorities have used voltage reduction for decades to reduce power quickly during a peak load emergency or power supply shortage. In the past, such voltage reductions were referred to as brownouts because of the dimming effect voltage reduction has on incandescent lightbulbs.

For the most part, the term no longer applies now that the newer generation of compact fluorescent lighting (CFL) and light-emitting diode (LED) lights remain bright at all voltages. Utilities can operate with reduced voltage on a continuous basis for energy conservation or during peak load periods for demand reduction.

When voltage reduction is performed at all times (24 hours per day, seven days a week), it is commonly referred to as CVR. This is because 24/7 operation is primarily intended to promote energy conservation. If voltage reduction is used only during peak load periods for purposes of peak shaving, this is technically voltage reduction or voltage optimization.

Reducing the voltage and the peak demand at a time that coincides with the peak load of the energy supplier can reduce the capacity charge the utility pays to its supplier. Reducing the voltage during the local utility’s peak load period will lower the utility’s peak electrical demand, possibly enabling the utility to defer adding capacity to its system or eliminate such additions altogether.

Why Do It?

There are several benefits for utilities to perform CVR:

• Peak shaving to lower peak demand, thus avoiding higher charges or capital expenses

• Energy conservation

• Lowering demand charges

• Potential lowering of greenhouse gas emissions

• Meeting regulator requirements or mandates

• Mitigating voltage lowering and potential reverse-power flows as a result of emerging DG and multidirectional power flow.

One of the concerns people may have with CVR is its impact on electrical devices. However, electric utility experience, backed by extensive laboratory experiments from industry research organizations such as the Electric Power Research Institute and Pacific Northwest National Laboratories has shown most electrical appliances consume less electricity without significant loss of performance, adverse consequences or negative impacts on the appliances when operated at a reduced voltage. In fact, they tend to operate more efficiently with reduced voltage. In addition, the use of less electricity results in a lower cost to run the appliance.

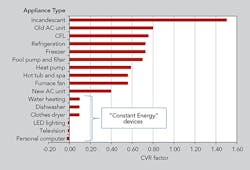

The simple example of an incandescent lightbulb illustrates the CVR concept. The lightbulb is basically a resistor. Using Ohm’s law, the power consumed by the lightbulb varies with the square of the voltage. Therefore, lowering the voltage on the lightbulb will lower the energy consumed by the light. Electric utilities use the term “CVR factor” to identify the load-to-voltage sensitivity of an electrical device.

For an ideal incandescent lightbulb, the CVR factor would be 2, meaning reducing the voltage by 1% results in a 2% drop in the energy consumed by the lightbulb. In reality, incandescent lightbulbs are not perfect resistors, because the resistance of the lightbulb changes as the bulb heats up. Laboratory experiments have shown the CVR factor for an incandescent lightbulb is actually around 1.5 because of this effect.

CVR factors are important to understand the impact that reduced voltage has on certain devices. This helps to determine on which circuits a utility chooses to run CVR for the highest impact. Some utilities have performed extensive analytics to determine how to get the most out of CVR.

Most electrical appliances exhibit a positive load-to-voltage sensitivity (CVR factor). Most appliances have a CVR factor of at least 50% and will consume less energy when lowering the voltage. Some appliances exhibit near-zero load-to-voltage sensitivity. These devices are mostly power electronics-based with switched power supplies that automatically adjust the voltage delivered to the power supplies’ internal components.

Supplied voltage varies, so the device exhibits a constant-power behavior. If voltage delivered to the device is lowered, the device will automatically draw more current to maintain roughly constant-power behavior. Clearly, a distribution feeder that serves a very high percentage of constant-power appliances would have a poor CVR factor and, therefore, would not be a good candidate for CVR.

When the utility reduces the voltage delivered to a residence or commercial establishment, the CVR factor for the premise or commercial establishment is the aggregate effect of all electrical appliances contained within the location. Similarly, when the utility reduces voltage to an entire substation bus or an entire distribution feeder, the CVR factor of that bus or feeder is the aggregate effect of all electrical appliances served by the substation bus or feeder.

Industry Experience

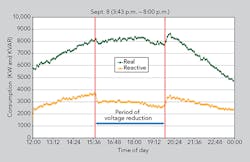

There is considerable industry experience with CVR. In addition, numerous utilities have conducted field trials to demonstrate the effectiveness of CVR on their electric distribution system. The results published by these utilities have shown the CVR factors are typically between 0.6 and 0.8, meaning reducing the voltage by 1% results in an energy reduction of between 0.6% and 0.8%. Likewise, reducing the voltage by 3% during peak load conditions would reduce peak demand by 2.1% to 2.4%. For a utility with a peak load of 100 MW, that could amount to almost US$200,000 per year.

CVR at Pee Dee Electric Cooperative

PDEC serves approximately 30,000 member-owners in Chesterfield, Darlington, Dillon, Florence, Lee and Marion counties in South Carolina, U.S. One of 20 distribution co-ops in the state, PDEC buys all its wholesale power from Central Electric Power Cooperative (Central). Because the 20 co-ops use their combined buying power as a group, each member co-op is assigned a demand charge every month based on their contribution to the statewide peak. Driven by the characteristic residential load profile, the statewide peak is relatively predictable if one studies historic loading and temperatures.

PDEC began using CVR in the 1980s to make the most of this particular coincident peak demand billing system. In fact, the potential savings of CVR were used as justification for the co-op to invest in a supervisory control and data acquisition (SCADA) system. While the normal voltage targets for PDEC’s station regulators were 125 V (to allow for voltage drop along the lines), during a potential peak period, an operator would manually lower regulator voltages to predefined targets based on what could be tolerated by the system at that time.

Today, half of PDEC’s substations are feeder-regulated while the other half are still bus-regulated. Naturally, a system has more lowering flexibility with feeder-regulated substations because, with a bus-regulated substation, a utility can only lower the voltage as much as the least-tolerant circuit will allow.

As one might expect, the process has changed some over the past 30 years. Initially, taking load control, as the team members call it, required a trip to the office to lower the regulators and then another one to reset them at the end of the control period. Every now and then, when the cooperative was having SCADA troubles in the system’s infancy, CVR was actually implemented in the field — with employees from the engineering and operations departments being dispatched to lower the regulators manually using switches inside of each substation’s remote terminal unit cabinet.

Eventually, the SCADA problems were all worked out, and the ability to lower the regulators by connecting in from home made life much simpler for the team members. Today, the entire process is automated with a signal from Central being used to lower and reset the regulators automatically using standard water heater control switches.

Initially, there was some concern the benefits of CVR were only temporary. For example, the belief in the Central system was, by lowering voltage at 3 p.m., this would only reduce the demand for 30 minutes or so until the thermostat-driven loads had a chance to respond. Therefore, for years, the cooperatives in South Carolina — guided by Central — would reserve the CVR step in the load control process for the two-hour window when the peak was most likely to occur (6 a.m. to 8 am in the winter and 4 p.m. to 6 p.m. in the summer). However, earlier afternoon peaks (the hours ending 3 p.m. and 4 p.m., for example) kept occurring.

After much study, it was determined the impacts of CVR would last throughout the entire control period. For this reason, the summer CVR windows were widened. Typically, regulator voltage is lowered from 6 a.m. to 9 a.m. on a cold morning and from 3 p.m. to 7 p.m. on a hot afternoon.

The most recent change is the splitting of the production and transmission peaks. Because Central now purchases from Santee Cooper and Duke, three different peaks have to be monitored. All 20 co-ops in South Carolina are held accountable for their contributions to the statewide transmission peak. However, the generation peaks (production demand charges) are based on the part of the state in which the substation in question resides. All of PDEC’s substations are served by the Central–Santee Cooper lines. Duke feeds five of Central’s distribution cooperatives in the upper part of the state.

Based on all studies performed by PDEC, the co-op’s CVR factor is close to 1.0. Typical target voltages during peak periods range from 118 V to 123 V, depending on how much the feeder or bus can tolerate. The co-op estimates it saved between $500,000 and $600,000 on demand charges in 2014 alone. The SCADA system has paid for itself many times over in the past 30 years.

Positive Results

CVR is growing in popularity because it provides a noninvasive approach to demand reduction and energy efficiency. Penetration of DG provides another emerging reason for utilities to consider lowering the voltage on the electric distribution system.

PDEC’s experience demonstrates low-cost strategies for implementing and using CVR, providing lessons learned for utilities seeking to take full advantage of its benefits.

Rob Ardis ([email protected]) is COO of Pee Dee Electric Cooperative in Darlington, South Carolina, U.S. He holds bachelor’s degrees in electrical engineering, physics and mathematics, and is a registered professional engineer. He is an IEEE member, a member of the National Society of Professional Engineers, and has served as president of his chapter of the South Carolina Society of Professional Engineers and the Engineering Association of the Electric Cooperatives of South Carolina. After serving as COO of PDEC for 10 years, Ardis became president and CEO of Santee Electric Cooperative on Aug. 1, 2015.

Robert Uluski ([email protected]) is vice president of distribution automation and distribution management system at UISOL, an Alstom Co. Uluski holds BSEE and MSEE degrees, and is a registered professional engineer. He is one of the nation’s leading technology and business experts on electric power system automation. Uluski holds various leadership positions with the IEEE Power & Energy Society. In 2010, IEEE PES awarded him the Douglas M. Staszesky Award for contributions in the field

of distribution automation.