Asset Automation Helps Finnish Utility’s SAIDI

Helen Electricity Network Ltd. is the city-owned electricity distribution network operator for Helsinki, Finland, regulated by the Finnish Energy Authority. The utility’s parent company, Helen Ltd., is responsible for the retail market, electricity and district heating businesses, and new customer energy services. Helsinki has a population of around 660,000, and the distribution network supplies more than 400,000 industrial, commercial and residential customers. As part of the business operation model in Finland and for Helen, all network construction and maintenance work is outsourced to service providers with long-term contracts. The large project contracts are awarded in compliance with the EU’s open competition procedures.

As Helen is city-owned, the customers are, in fact, the owners of the utility. Therefore, providing a reliable and quality supply at a reasonable cost is an ever-present target and challenge. The city’s largest customers include public and private services that are highly vulnerable in the event of an electricity supply failure, which has customer interruption costs of some €33/kWh (US$40/kWh) in the city center.

Helen has made many major investments in its 110-kV sub-transmission network, which is meshed connected with N-1 criteria and sufficiently robust to distribute power generated by the city’s combined heat and power (CHP) plants. Almost all the utility’s existing 25 primary substations — equipped with SF6-insulated switchgear — are designed with 100% redundancy, for example, with two high-voltage/medium-voltage (110/20-kV) transformers and duplicate 20-kV bus bars. The design reliability criteria also specify that all medium-voltage (10-kV and 20-kV) substations have 100% reserve-capacity interconnections from neighboring high-voltage/medium-voltage (HV/MV) substations.

The MV network consists of underground cables — meshed with open points and operated radially — throughout the city. Typically, the 10-kV radial networks have a capacity rating of 5 MVA and the 20-kV radial networks 10 MVA, but the current overall loading in the city is relatively low. Considerable efforts have been made to provide effective and efficient maintenance procedures for operational staff to manage network fault events, with a focus on asset automation.

Substation Refurbishment

Helen commissioned numerous substations from 1980 to 1990 that have a design service life of 25 years to 30 years for the secondary substations and 40 years to 50 years for the primary substations. Helen conducted a refurbishment program of the secondary substations from 2007 to 2011, and in 2013, it decided to continue the refurbishments at an increased pace. The principal reasons for this decision were as follows:

- The secondary systems were aging, as their optimal lifetime was only 50% of primary substations.

- Fault rates were increasing on products no longer supported by the manufacturer (Siemens AG).

With self-supervision, it was possible to achieve higher reliability and halve the periodical protection testing costs by increasing the test interval from three years to six years.

- Coverable disturbance and event-recording functionalities

- Protection functionalities like MV cable terminal earth-fault function, directional-overcurrent function, MV short-circuit location

- Substation automation and bus technology (IEC 61850) enabling large volumes of signals from remote terminal units (RTUs) and supervisory control and data acquisition (SCADA) with more accurate real-time information on primary and device faults for operators, improved interoperability between devices from different manufacturers, and the use of fast generic object-oriented substation event (GOOSE) signals between intelligent electronic devices (IEDs).

The completion of the first phase of the primary substation secondary system refurbishment projects continued based on turnkey contracts at the rate of two projects to three projects per year. The second phase, started in 2014, was completed mainly by Siemens using SIPROTEC 5 and SICAM products. The remaining substations were completed by ABB using REX 600 series and RTU560 devices. The pace of this refurbishment program has now decreased to a rate of one project to two projects annually. Today, all Helen’s primary substations have a modern substation automation system, with the oldest substations still relying on serial communication.

Secondary Substation Automation

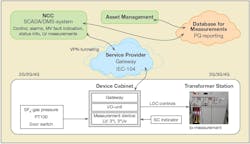

Helen’s secondary substations were commissioned as a simple ring-main unit (RMU) type prior to the introduction of substation automation. Therefore, it was not until 2008 that Helen established the business case for automation. This was based on new technologies in the market, with the cost level of communication and technology decreasing while customer interruption costs in Finland were increasing. In 2009, Helen produced its full specification for secondary substation system automation:

- Commercial mobile communication (2.5G, 3G and 4G)

- Remote control of load disconnectors

- MV short-circuit and earth-fault indication

- Secondary substation alarm indication

- Distribution transformer load-level measurement

- Power quality measurement on low-voltage (LV) side.

The automated secondary substations selected were the normally open-point substations positioned at the 50% energy point on the ring-connected MV feeders. These automation projects were separate from the secondary substation refurbishment activity.

Furthermore, the telecommunication works were included in the agreement as well as turnkey maintenance of the complete system for 15 years. The project continues today as part of normal network construction with the automation provider and the network construction partner, with the intent that every new and refurbished secondary substation will be automated. This amounts to 50 automated secondary substations per year, including the telecommunication and maintenance activities included in the contract and in ongoing projects.

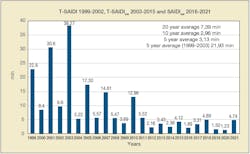

This increased level of automation already has resulted in significant advantages. For example, thousands of planned remote disconnector operations have been undertaken. On more than 200-MV network faults, automation has resulted in rapid restoration of supply to 50% of the affected customers and fault isolation has been accelerated for the remaining customers. Overall, the automation completed to date, has improved Helen’s system interruption duration index (SAIDI) by reducing the interruption about 0.5 minutes per annum.

The measured mobile communication reliability level between SCADA and the secondary substations has been above 99%. Previously, the MV earth-fault indications had not been fully reliable because of Helen’s compensated networks, but this is no longer a problem thanks to the utility’s installed earth-fault protection.

Primary Substation Automation

Helen installed five new primary substations between 2009 and 2017 to satisfy the 1% to 2% growth in demand that has now ceased. As it had to maintain its 100% MV network reserve design standard, additional new MV substations were installed that have effectively decreased the geographical area supplied by the existing aging substations, thereby increasing network reliability.

All the new substations were delivered in accordance with the turnkey contract, which included the installation of the process devices from ABB and Siemens. The substations were equipped with the specified latest automation technology:

- IEC 60870-5-104 remote control protocol with station level automation

- Some functional integration at HV level and one IED/bay at MV level

- Numerical IEDs with coverable self-supervision and fault recording.

- IEC 61850 station bus communication with rapid spanning tree protocol (RSTP)

- GOOSE signals mainly for control interlocking

- New advanced HV- and MV-level protection functions and other functions

- Transformer and switchgear condition monitoring (gas and partial discharge measurements)

- Sensors and IEC 61850-9-2 communication in one application (in the Kalasatama neighborhood).

The new substations have decreased the distribution area of the neighboring substations by 25%. This has decreased the SAIDI by around 0.5 minutes per year.

Earth-Fault Compensation

Some preconditions enable the MV network earth-fault protection to be used with an alarm-only method without tripping the circuit breaker. For this to be possible, earthing conditions must be solid and the touch voltages sufficiently low. Underground cable networks enable the possibility to avoid earth-fault arcs, as most of the fault current flows through the earthed cable screen. However, this requires the cable network to be in reasonable condition and not too old, to avoid cross-country faults.

In Helen’s 10-kV isolated network, the earth-fault protection has been an alarm-only system for decades, operating with success. In the 20-kV compensated network, there was an earlier tripping system because of the higher earth-fault currents and touch voltages compared to the 10-kV network. In 2008, Helen kicked off a 20-kV earth-fault compensation project, aiming for the following results:

Change the earth-fault protection of the 20-kV network to an alarm-only mode, so that 70% of earth faults can be isolated without outages to customers. In practice, this leads to a situation where only 50% of MV faults cause outages to customers. In compensated networks, the earth faults cause reduced stresses for the voltage transformers (Helen experienced many MV bus bar short-circuit faults between 1995-2007, caused by voltage transformer faults). Earth faults in a compensated network cause lower-voltage stresses (transients) transmitted to the LV side of the transformer.

The project started with a pilot installation at the 20-kV Pukinmäki greenfield substation. In 2012, the project con-tinued with a full rollout and was finalized in 2018. The earth-fault compensation system is now installed in 13 substations, increasing Helen’s total to 26 compensating systems.

Technically, Helen uses centralized compensation with 200-A to 500-Amp Petersen coils. The coils are connected to a 20-kV star point of the main transformers. Current injection is used to help the regulator see the size of the network without moving the position of the coil. The compensation degree is 10 A overcompensated and an additional resistor with 10-A current is used momentarily (for 3 sec) after the earth fault starts. Earth-fault protection is used with the cos φ function. Additional earth-fault indication devices, including intermittent, transient, harmonic and admittance functions, are used.

Commissioning tests must be conducted at night because primary earth-fault tests are executed with customers on the same network. At first, there were some problems and those tests also caused some cross-country fault situations. With the most recent projects, there have been no significant problems. All earth faults initially are intermittent earth faults, and they evolve usually within minutes to stationary-state earth faults.

The earth-fault protection and indication has been operating at a very reliable level. Helen has experienced many earth faults and 70% of them were isolated without outages to customers. The remaining 30% evolved into short-circuits or cross-country faults. No voltage transformer faults occurred between 2008-2020 and only one fault occurred in 2021. This likely initialized the high-phase voltage that arises during an earth fault. The effect of the compensation decreased SAIDI by 1.5 minutes annually.

Network Visibility

The last automated part of the network was completed at the customer terminals. In Finland, all utilities must provide customers with automated meter reading (AMR) systems. Helen installed digital energy meters and reading systems between 2008 and 2013, so its customers have had AMR for more than seven years. Customers get hourly billing according to real-time measurements and they can follow their demand using the customer service system. The reading is taken every day, with the communication mainly going to mobile devices.

Significant SAIDI Reductions

Helen has sought to provide its customers with a high-quality, reliable and secure supply of electrical energy. As a result, its five-year average SAIDI level has decreased during the past 20 years from more than 20 minutes to 3 minutes. In 2020, Helen’s SAIDI was only 1.23 minutes — a value that is probably among the lowest in Europe. Simultaneously, customer tariffs have been maintained at a reasonable level and, compared with the purchasing-power-adjusted residential customer tariffs of other European capital cities, Helsinki has the lowest tariffs.

These results are comparable with other cities that have underground cable distribution networks. They have been achieved by applying network design standards, a meshed network structure, strong and proven primary solutions, and effective maintenance and operation. Automation has played a significant role: Substation automation, secondary substation automation, earth-fault protection alarms and AMR systems have been the tools of choice for Helen coupled with appropriate and timely management investment decisions.

One important decision now facing Helen is the replacement of many fossil-fuel-fired CHP plants in Helsinki. The utility has decided to decommission the Hanasaari coal-fired power plant in 2023 and Salmisaari CHP power plant in 2024. The city will still require heat, so it is very likely large heat pumps will be needed to produce the energy currently available from the CHP plants and meet the increasing customer demand for electricity.

Mika Loukkalahti ([email protected]) studied electrical engineering at Tampere University of Technology, receiving his master’s degree in 1996. He joined Helsinki Energy in 1997 as a protection engineer, with responsibility for substation and network automation and power supply reliability. Currently, Loukkalahti leads life-cycle management and technological development at the utility. He is a member of the Finnish Study Committee and former member of the CIGRE B5 (Protection,

Automation and Control Committee), and he has given several presentations at courses and seminars.

About the Author

Mika Loukkalahti

Mika Loukkalahti, M.Sc., is head of principle planning at Helen Electricity Network Ltd. in Helsinki, Finland. Loukkalahti is responsible for principle and system-level planning and specification of the electrical network. He has many years of experience in system-level planning, substation automation and protection. He also has been an active member of several CIGRÉ B5 working groups on substation automation.