ABB's SafeLink CB secondary SF6 gas-insulated ring main unit (RMU) switchgear was designed and developed at the company's modern MV production facility in Nashik, India. By employing numerical simulation tools ➔ 1 for efficient development, ABB engineers were able to ensure an optimized design, resulting in a reliable, safe and robust solution.

1 Design optimization through simulation tools

Sound manufacturing and technology

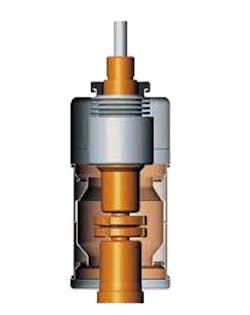

At the heart of SafeLink CB lie ABB vacuum interrupters, a circuit breaker and EL2 actuators. The switchgear is based on the highly reliable VG-series vacuum interrupters (VIs) ➔ 2, also manufactured at ABB's world-class facilities ➔ 3. VI technology enables high dielectric strength at short distances, making it ideal for use in MV products, since interruption of the circuit is guaranteed when the contact separation takes place a few milliseconds before the current passes through natural current zero. The special geometry of the contacts and the specially selected material, as well as the limited duration and low voltage of the arc, guarantee minimum contact wear and long life – 30,000 operations at rated current. Furthermore, the vacuum provides protection by preventing oxidation and contamination of contacts.

As standardization is important in engineering quality products, proven EL spring actuators are used for the vacuum circuit breaker (VCB) module. EL2 actuators have multiple built-in features and are rugged, durable and capable of a high number of mechanical operations.

3 Vacuum interrupter manufacturing at ABB's factory in Ratingen, Germany

ABB's cable bushings for SF6 switchgear also have demonstrated their high performance across a large installed base in distribution networks, power stations and industrial complexes. In locations with humidity or condensation problems, for example, the use of cable bushings together with fully screened connectors is particularly valuable.

The environmentally friendly manufacturing processes involved in the production of the SafeLink CB RMU switchgear conform with ISO 9001 and ISO 14001. The materials are carefully selected to ensure maximum reuse at the end of life and have a recycling capability of around 95 percent.

Module design and rating

The SafeLink CB RMU switchgear covers the most common nominal voltage rating of 12 kV, maximum current of 630 A and short-circuit current of 21 kA. It is suitable for both indoor and outdoor conditions. Currently it is available as non-extensible and extensible configurations of CVC as well as extensible configurations of V and C.

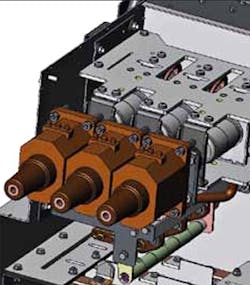

The C module ➔ 4 is a cable-switch module with integrated test point facility. This three-position switch disconnector and earthing switch uses SF6 gas as an arc-quenching and insulating medium. In the open position, the switch satisfies the disconnector requirements. A single spring-latched mechanism for load break and earthing functions is used with a common operating shaft. Each set of test-point bushings on the bottom side of the tank have separate covers interlocked with the respective earthing switches.

The V module is a vacuum circuit breaker with relay-based transformer protection. It is designed with ABB's VG5 vacuum interrupters for short-circuit current interruption ➔ 5. A three-position disconnector is connected in series with the circuit breaker on the busbar side. The operation between the vacuum circuit breaker and the disconnector, as well as between the disconnector and the earthing switch, is mechanically interlocked. The EL2 spring actuator with trip-free and auto-reclosing facility is used as the operating mechanism. If the closing spring is recharged after a closing operation, it is possible to perform an open-close-open sequence. The EL mechanism has a built-in mechanical anti-pumping device, which prevents reclosing due to either electrical or mechanical commands.

Completely sealed enclosure

To ensure a high level of safety, SafeLink CB is housed in a hermetically sealed, precision-welded stainless steel tank containing all the live components and switching functions. Its gas-insulated switchgear (GIS) design uses SF6 gas and has a rated filling pressure of 1.2 bar (absolute). Electrical and mechanical bushings penetrating the tank are clamped and sealed by high-quality O-rings. Designed to the highest standards and constructed by ABB welding robots, the stainless steel tank provides ingress protection of level IP67 and is classified as a sealed pressure system in accordance with IEC standards. The sealing guarantees a leakage rate of less than 0.1 percent per year, rendering the tank maintenance-free throughout the equipment's specified operating life.

Features

Because of its footprint and cable termination, SafeLink CB is compatible with installations that require cable entry from the sides and rear of the switchgear.

The basic insulation level for 17.5 kV nominal voltage (ie, 38 kV/95 kVp) has been achieved despite its compact design and gas filling pressure.

The circuit breaker with EL2 spring actuators is suitable for a high number of mechanical operations, including up to 5,000 close-open operations.

SafeLink CB offers enhanced safety features, is internal-arc classified and conforms to IEC (International Electrotechnical Commission) standards. All mechanisms and cable compartments are provided with safety interlocks, which restrict access to the equipment and therefore increase operator safety. The complete enclosure has IP54 ingress protection. Operator safety is also ensured through the arc-proof design of the cable compartments.

In its extensible version, SafeLink CB provides the unique flexibility of either a factory-fitted busbar extension or a provision for future extension of the ring main unit.

Complete automation package solutions including motorization of operating mechanisms and remote control and monitoring can be provided. Smart grid solutions suitable for utility installations, flexible provision of busbar extensions and a wide range of accessories are also available.

The ring core current transformers (CTs) for the vacuum circuit breaker module are mounted on the tee-off side cable bushings. SafeLink CB has a self-powered relay that, should a fault occur, utilizes the energy from the CTs to energize the trip coil. A human-machine interface enables the configuration of protection schemes.

The SafeLink CB design concept has the flexibility to cover a wide variety of application needs, from basic installations to advanced systems. SafeLink CB is maintenance- free, robust, reliable and safe, boasting many important technical advantages. In addition to its compact footprint, SafeLink CB's simple installation and design make it an extremely competitive solution for secondary distribution networks.

Pravin Futane

Subbiah Thevar

Dukkaiappan V. Ramesh

ABB Ltd, Medium Voltage Products

Nashik, India

[email protected]

[email protected]

[email protected]

Gerhard Salge

ABB AG, Medium Voltage Products

Ratingen, Germany

[email protected]