Lineman Invents New Stringing Block for Industry

Robert Seekell, a 20-year power lineman, OSHA outreach trainer and T&D instructor, has a passion for training to make the line trade safer. Rob is a member of Local 659 and resident of Boise, Idaho, worked at Northwest Lineman College for five years and traveled around the US to work as a lineman.

For decades, he has strived to make the line trade more efficient. To help linemen to save time and improve their safety in the field, he has invented a new stringing block design for the power industry.

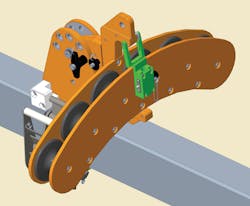

Called the Condux Radius Safety (CRS) Block, the nonconductive stringing block has two patents on the base and top sections. Seekell designed the block to use advanced new technologies and materials linemen are starting to use today in the field.

By partnering with Condux International, a Mankato, Minnesota-based company, Seekell is leveraging the company’s manufacturing expertise to transform the concept into reality. Condux is currently in the final stages of development creating the CRS Block with a patented base and block body. The outer body is high vis in color, and all the conductive pieces are covered with a nonconductive coating. The company plans to launch the 20.2-in. version and a 10-in. model initially with larger sizes available in the future.

“This is going to be the first radius block in different sizes that will mount to the utility crossarms, attach to a pole or can hang,” Seekell said. “The block will not only be safer, but also be faster to install.”

Saving Time in the Field

The average install time on a block used today in the field is one to two minutes, and the CRS Block is said to take only 12 seconds to install. Due to its ratchet strap design, the CRS Block allows linemen to use their 3/4 rattle gun to speed up the installation. The design of the base can also adjust to five different angles with the pull of a pin, and the conductor never has to be removed to change the angle like the old X100 blocks. This step alone made it a safer block, Seekell says. When mounted on the arm the new block can pivot completely upside down for upstrains.

To make the CRS Block even lighter, the base can be removed when in a hanging application. Other 20-in. diameter blocks weigh around 45 to 55 LBSs., but the 20-inch CRS Block weighs 25 lbs. without the base. The base will also allow the old X 100 blocks to drop into the base so the linemen can use the new features of the base to add efficiency to the old block. The block can be used on all types of conductors and fiber to mitigate about any angle needed for a stringing project.

“There has never been a stringing block in the industry with so many safety features to improve safety and help to advance the electrical circuits,” Seekell says. “I felt I nailed it when I made a block that was not only safer, lighter but faster for our trade. This is a tool made for linemen by a lineman.”

Installing Tree Wire and New Age Carbon Core Conductors

Linemen can also use the CRS Block to install new age carbon core conductors or insulated tree wire, which needs a larger radius stringing block so installers don’t damage core or insulation.

With insulated tree wire applications today, some companies have been de-energizing the power line to pull in the insulated tree wire because they need the larger diameter radius for stringing the tree wire, and the blocks they are using only hang under the arm.

“If they had the CRS Block, it would mitigate the issue and make the job safer, faster and keep the lights on,” Seekell says.

Assisting Drone Stringing Operations

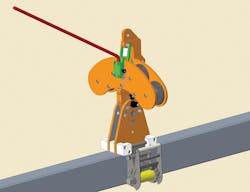

As the CRS Block is introduced into the marketplace, Seekell envisions it also being used as a tool for drone stringing operations. The top has a spring-loaded inward opening gate to trap the pull line or conductor to make wire stringing jobs in the United States safer and faster. The new design has a non-conductive removeable guide arm to assist the drone when stringing.

“With drone technology improving, we are going to see more drone use in the power industry,” Seekell said.

Seekell has reached out to many drone companies to understand their challenges in the field to build a block that will help mitigate any issues they are facing.

“Linemen are going to be working more and more energized circuits because it is harder to deenergize the customers,” he said. “With all the safety and efficiency that was built into my block, this will make our trade safer and help take care of the growing need to improve our grid.”

Seekell said he feels he has been blessed to have the opportunity to work in such a great trade and work side by side with some of the greatest lineman and industry professionals who helped him with his skill set and experience gained. He wanted to thank his friends, pole buddies and family that has helped in the development of the new CRS block and base. In the future, he plans to introduce more tools to improve linemen’s safety and efficiency.

About the Author

Amy Fischbach

Electric Utilities Operations

Amy Fischbach is the Field Editor for T&D World magazine and manages the Electric Utility Operations section. She is the host of the Line Life Podcast, which celebrates the grit, courage and inspirational teamwork of the line trade. She also works on the annual Lineworker Supplement and the Vegetation Management Supplement as well as the Lineman Life and Lineman's Rodeo News enewsletters. Amy also covers events such as the Trees & Utilities conference and the International Lineman's Rodeo. She is the past president of the ASBPE Educational Foundation and ASBPE and earned her bachelor's and master's degrees in journalism from Kansas State University. She can be reached at [email protected].