Con Edison and ULC Technologies Unveil Cable Splicing Machine for Improved Worker Safety, Efficiency and Grid Reliability

ULC Technologies, a company specializing in energy industry robotics and automation, and Con Edison Company of New York, operator of one of the world’s largest energy delivery systems, have recently developed and field tested a machine that automates the termination of medium voltage cables to enable more reliable and resilient connections within the power grid and improve the safety of utility workers. This new field-demonstrable prototype Cable Splicing Machine will allow utility workers to improve the repeatability and consistency of critical connections within the electric grid by automating cable end preparation while minimizing worker exposure to high voltages.

The world relies on a reliable and resilient electric grid to deliver power to homes, businesses, and organizations, the companies stated.

“At Con Edison worker safety is paramount. The technology used in this tool will enable our workers to splice high voltage cables, efficiently, uniformly, and most importantly more safely,” said Patrick McHugh, senior vice president, Con Edison Electric Operations. “When you reduce the risk of performing thousands of splices each year, improve their accuracy and efficiency, it benefits workers, grid reliability, cost effectiveness and value. That’s a win, win, win for Con Edison, its workers, customers and the industry.”

ULC Technologies has created an automated cable-end preparation system capable of performing complex operations on medium-voltage feeder cables in underground vaults. The primary drivers for this technology are to improve the safety of utility workers, shorten the overall feeder outage duration to reduce the stress on the grid and improve network resiliency. This is particularly important as underground distribution feeder outages occur during adverse weather conditions such as heat waves and storms that place significant stress on the electric grid.

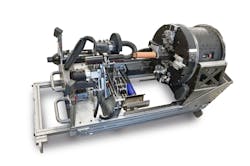

The machine consists of several independent subsystems controlled through a centralized processing computer and user interface.

“The Cable Splicing Machine can be secured onto the middle of an uncut cable in the field and uses electrical actuators to provide precise coordinated motion along the axial and circumferential directions, including continuous 360-degree operation,” says Ali Asmari, director of infrastructure operations at ULC Technologies. “The machine’s tool plate consists of numerous tools capable of stripping back each layer of the cable to a desired dimension using precision tool depth controls.”

Tooling has been updated to improve the robustness and adaptability so different types of cables can be addressed even faster than before with future development. Several auxiliary subsystems carry out additional steps such as shorting and cutting the cable. This, in combination with live camera feeds, allows an operator to successfully monitor and verify the process from beginning to end from outside the manhole with no physical human intervention.

ULC Technologies and Con Edison began field trials of the cable splicing machine this year. After the splicers lowered the machine into the structure and then inserted the cable inside the machine, the machine completed three autonomous operations to prepare the cable in about 25 to 30 minutes per each phase of the medium voltage cable. The technology will be presented and demonstrated in Booth 760 at the upcoming Distributech Conference, which takes place February 26 to March 1 at the Orange County Convention Center in Orlando, Florida.