ComEd Leverages Voltage Optimization for Energy Savings

Through its large-scale voltage optimization program, Commonwealth Edison (ComEd), one of the largest electric utilities in the U.S., is connecting its 4 million northern Illinois customers to better electric service. The program is enabled by the Illinois Future Energy Jobs Act (FEJA) to enhance energy efficiency options and save on customer energy costs in ComEd’s service territory, which encompasses 11,400 square miles and consists of more than 70,000 miles of power lines.

The primary goal of the program is to optimize customer service voltages and create equitable energy savings for customers across the service territory. In addition, VO is cutting the amount of fuel needed for power generation while lowering peak generation demand, mitigating system energy losses and improving system stability. ComEd customers do not need to change any of their energy usage behaviors to benefit from energy savings produced by the program.

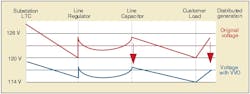

In conjunction with the LTC adjustments, each feeder distribution line is designed with VO-specific capacitor banks and voltage regulators to effectively tighten the voltage range without exceeding the lower voltage threshold limit.

These devices, along with end-of-line (EOL) AMI meters, provide data to the VO algorithm, which controls the capacitor banks, voltage regulators, and transformer LTC. Successful activation of VO on a distribution feeder results in an intelligent, real-time control of the voltage on the line to the end customers.

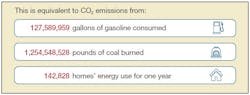

The program began with analysis of the entire ComEd distribution system that identified about 500 substations where VO deployment demonstrated a potential for cost beneficial impact for the customers. The program completed its first station activation in 2018 and is projected to complete initially identified stations by 2026. Once this first phase of the program is completed, the anticipated annual energy savings is projected to exceed 1,600 GWh.

VO Operations

The operation of VO is achieved using a combination of intelligent devices on the distribution system controlled by a centralized software platform, which runs on a VVO algorithm. ComEd has a dedicated VO operations team that performs the initial commissioning of these new systems and devices and operates, maintains, and oversees the entire program.

The VO team works with different internal groups, such as capacity planning, project management, distribution automation, information technology, relay and protection, regional engineering, SCADA data maintenance, and distribution and substation field testing personnel to achieve successful activation and maintenance of a VO site.

The annual process begins with capacity planning selecting the top priority stations that will enable the team to meet the total energy savings commitment for the specified year. These are then provided to the project management team to manage budget, schedules, materials, and labor resources.

The relay and protection team provides the design details and settings for the station work and the capacity planning team provides design and settings for the distribution line feeder work. These design packages are then engineered, and drawings are sent out for the construction phase. Once the construction crews complete the work, the field-testing engineers configure load settings and test the equipment and associated wiring.

After field testing is completed, remote-end testing is performed and validated by both the SCADA data maintenance and VO operations team. The VO operations team then completes the process by modeling and linking all the components in the station to a central database, which enables VO to deliver energy savings to ComEd customers.

Today, the team uses templates and automated processes built and customized internally to move hundreds of points into the program’s database. These tools now enable the small VO team to manage significant workloads and deliver highly efficient energy to customers, enabling them to reduce energy consumption and costs of up to 2 percent annually. What’s more, these automated tools and processes are showcased to other departments across the company in an ongoing effort to share and deploy best practices.

This program allows the VO team to perform preventative maintenance more often and intelligently, leading to better year-round reliability and power quality. As the number of devices in the VO program grows, so will the cost savings provided by the new remote and automated conditional maintenance process. A similar maintenance process for VO voltage regulators is currently in development and is set to be deployed soon.

SCADA system rack is another innovation that allows the VO group to test and remotely troubleshoot SCADA communications and field controller settings in a lab environment. The test system simulates field equipment and SCADA network for a station. The unit has proven to be a valuable means of piloting and testing new equipment for field deployment.

Evaluation and Monitoring

Beyond the deployment of the technology in the field, it is essential to educate and build understanding among stakeholders about the benefits of VO. To that end, ComEd has worked with third party evaluators, regulators and other stakeholders to develop a systemwide conservation voltage reduction factor. The CVR factor is an index that is measured as the ratio of energy consumption reduction to the voltage reduction due to the deployment of VO.

A regression model has been developed to evaluate almost 200 feeders across the system with adequate VO enabled data. This has resulted in a load weighted average CVR factor throughout the system. Using this systemwide CVR factor, ComEd has developed algorithms to precisely estimate energy savings considering confounding factors like season, temperature, VO status, time of day, etc., in addition to reconstructing the data after necessary validation and correction.

After the VO operation is activated on a substation, the measurement and verification engineers collect necessary data and actively monitor the performance of that station to confirm energy savings and voltage reduction using developed algorithms. M&V engineers provide feedback when expected energy savings is not achieved, and actions needs to be taken to enhance VO operation.

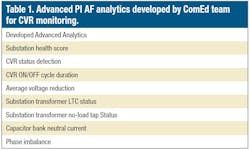

To fully leverage the value of VO system monitoring, ComEd is using a PI asset framework to continually monitor VO devices, perform advanced analytics, and process real-time notifications on system behaviors. Communication signals sent by the VO control platform and field measurements from VO devices are brought into the AF environment, where further analyses are performed and historized.

Based on these analytics, automated email notifications are generated and distributed to appropriate workgroups to raise situational awareness and promote rapid actions to ensure that VO systems are healthy and operating effectively.

In addition to using the PI-AF to perform advanced analyses and monitor behind-the-scenes system behaviors, the VO team is also using an alarm management and monitoring application. This application provides a front-and-center display which allows for incoming alarms and events to be filtered based on user defined criteria. Displays with specific criteria sets can be saved as views; examples of the views created by the VO group include capacitor bank alarms/events, communication issues with LTCs and line devices, and possible control failures.

The VO team continuously looks to automate manual processes, such as device creation and equipment functional testing, to reduce or eliminate labor-intensive tasks. ComEd invests in research and works with manufacturers on devices to add to the capabilities of the VO program. One such device is a dynamic VAR controller installed on the secondary line side providing data, control, and VAR support.

ComEd is continuously collaborating with the utility industry by publishing those successes and the standards they are built upon at various leading international conferences. ComEd is committed to delivering continued results for its customers through expansion and improvement in VO.

Acknowledgments

Other contributors to this article include: Cody Walsh, a member of the Voltage Optimization Operations team since June 2022; Luke Workman who has been supporting the Voltage Optimization group at ComEd for the past four years as a contractor and as a full time ComEd employee; Brooks Glisson, Sr., senior manager of Reliability Programs where he manages the Voltage Optimization department to increase efficiency and intelligence across ComEd’s distribution system; and Paul Pabst, Sr., the senior manager of Emerging Technology within ComEd’s Smart Grid Department.

Mark Procaccio ([email protected]) is a general engineer in Voltage Optimization (VO) group at ComEd where he is part of the operations (Op) team that handles many different aspects of daily operation within the VO system, like data mapping of telemeter points and remote-end testing of field devices. His research interests include field device automation, one-line diagram modeling, and SCADA communications.

Jason Pozen ([email protected]) is currently the manager of distribution automation at ComEd where he manages the Voltage Optimization (VO) Operations team and the VO program. Pozen holds a PE in Illinois and has over 20 years of power industry experience focused on transmission, distribution, substations, protective relaying, SCADA, communication systems, and networking.

Sheikh Rajib ([email protected]) is a senior engineer in the Voltage Optimization group. He brings 11 plus years of experience in the field of power engineering consulting. Rajib also has experience in designing transmission, distribution, and protection systems across North America and overseas.

Wen Fan ([email protected]) is a general engineer in Voltage Optimization group at ComEd where he leads measurement and verification (M&V), coordinates with Illinois Commerce Commission (ICC) and third-party evaluators to assess VO energy savings on distribution feeders. He is the Secretary of IEEE conservation voltage reduction (CVR) Task Force leading the effort to develop an IEEE standard on CVR M&V.

Ashraful Haque ([email protected]) is a general engineer in the Voltage Optimization group. He has a PhD in electrical engineering from Virginia Tech. His areas of expertise are decarbonization, renewable energy integration and EVs.

About the Author

Mark Procaccio

Mark Procaccio is a General Engineer in Voltage Optimization (VO) group at ComEd where he is part of the operations (Op) team that handles many different aspects of daily operation within the VO system, like data mapping of telemeter points and remote-end testing of field devices. His research interests include field device automation, one-line diagram modeling, and SCADA communications.

Jason Pozen

Jason Pozen is currently the manager of distribution automation at ComEd where he manages the Voltage Optimization (VO) Operations team and the VO program. Jason holds a PE in Illinois and has over 20 years of power industry experience focused on transmission, distribution, substations, protective relaying, SCADA, communication systems, and networking.

Sheikh Rajib

Sheikh Rajib is a Senior Engineer in the Voltage Optimization group. He brings 11 plus years of experience in the field of power engineering consulting. Rajib also has experience in designing transmission, distribution, and protection systems across North America and overseas.

Ashraful Haque

Ashraful Haque is a General Engineer in the Voltage Optimization group. He has a PhD in Electrical Engineering from Virginia Tech. His area of expertise are decarbonization, renewable energy integration, and electrical vehicles.