Keeping up with digital technology is never boring. Sure it’s frustrating, challenging and fascinating all at the same time, and it’s happening so rapidly it can’t be ignored. A few months ago “Charging Ahead” explored the latest advancements taking place in vegetation management technology. Normally that amount of coverage would be sufficient, but this technology is developing by quantum leaps and it’s critical to the entire power delivery industry.

Currently the typical vegetation management system supplies a broad view of the transmission line’s right-of-way (ROW), but more is possible. A next-gen platform provides near real-time data for the ROW’s present condition. It also needs the ability to predict future vegetation conditions. This perspective has been missing from conventional vegetation management systems.

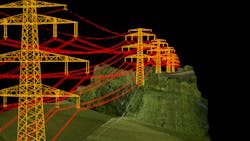

Platforms integrating artificial intelligence (AI), LiDAR (light distance and ranging), satellite data, and hyperspectral sensors are bringing vegetation management to this next level. They offer that end-to-end process, which will take the industry to a more user-friendly workflow. They also will improve outage times in a world that isn’t doing too good in that respect.

Power Interruptions are Growing

Late last year, the EIA (Energy Information Administration) published a report on the average duration of total annual power interruptions in the U.S. In the report, EIA said that 2020 (latest figures available) wasn’t a good year for the typical electricity customer. They experienced just over eight hours of electric power interruptions on the average. EIA went on to say that the 2020 outage rate was the highest recorded since they began collecting electricity reliability data in 2013.

This increase in interruptions is not because the industry is not taking this problem seriously. They are and their maintenance budgets reflect how important vegetation management is to the industry. For most utilities, vegetation management is the number one line item on their annual budgets. Accenture reports, “Utilities spend around US$6 to 8 billion annually on clearing vegetation from overhead lines.” But they also point out that investment and deployment of emerging technology, tools, and advanced analytic approaches could save utilities between 10% to 15% of their annual vegetation management spending.

Reducing the amount spent by 10-15% would save almost a billion dollars for the bottom line. What makes this task so daunting is the sheer amount of circuit miles in the power grid’s infrastructure. And they have to be inspected every year for a multitude of regulatory requirements.

Innovative Tools

To meet this challenge, It’s extremely important to take advantage of every technological innovation available today. State-of-the-art surveying and inspection technologies are making a significant difference, but they generate a great deal of data. However, advanced applications are improving the process of interpreting the massive amounts of line inspection data into actionable information.

As a result, the industry’s technology partners are developing the next generation vegetation management platforms. These innovative systems are taking advantage of AI technologies combined with cloud computing, but that isn’t all. Predictive analytics interpret what is taking place with vegetation and how it can affect the transmission line next to it.

Hitachi Vegetation Manager (HVM) is a closed-loop digital system that integrates work planning, risk management, and field patrols into an end-to-end vegetation management program. Talking with Jeff Pauska, digital product director, Hitachi Energy revealed insights for the HVM application. Mr. Pauska said, “The software connects ground and air patrols with field inspections/audits to back-office planning activities. HVM improves the accuracy and effectiveness of the vegetation manager and arborist/forester job activities and planning efforts.”

Pauska explained, “Every piece of information that is provided by field or back-office users within the system is a reinforcement learning data point, which the AI analyzes to improve risk-based predictions and outcomes. Since we cover end-to-end vegetation business processes, and subsequently can capture every point at which utilities have “eyes-on target,” or in this case, vegetation threats/work around power lines, we enable them to make better decisions through the use of a reinforcement model, which improves accuracy of the AI inferences over time.”

He also noted, “The various sources the AI is digesting includes photos, videos, LiDAR, satellite imaging and more. HVM also digitalizes institutional knowledge about work sites and assists in field planning, such as moving machinery or equipment into a work area, location of potential work hazards, customer preferences or concerns, and more.”

Digital Twin

AI, advanced algorithms, cloud computing, and enriched aerial surveying are a few of the innovative technologies improving vegetation management systems, but there is another enhancement that’s becoming a real gamer changer. It’s called a digital twin. It’s a technology that has proven itself in power plants, windfarms, and digital substations to name a few applications. Recently there has been a growing interest in utilizing interactive digital twin technology with vegetation management systems.

With power outages increasing and extreme weather events becoming more numerous, it’s time for reexamining vegetation management technologies to improve practices. Digital twin technology seems to be an ideal application for a virtual representation of transmission assets that can automatically identify what is happening on the ROW. Recently Charging Ahead had a conversation with Dr. Alan Drew, business development and sales manager SIEAERO at Siemens Energy.

Drew began the discussion saying, “Siemens Energy has developed a high-end multi-sensor system, as well as AI analytics, to provide an overhead transmission line inspection service known as SIEAERO. This system was developed to produce a more precise, comprehensive high-resolution imaging for the complex requirements of overhead line inspections. The sensor system consists of a LiDAR scanner, RGB (red, green, blue) visual imaging, IR (infrared) sensors and a UV (ultraviolet) sensor. The scanned data’s location is identified by highly accurate GPS (global positioning system) coordinates. Powerful computing applications combine all of this data to create the 3D digital twin of the transmission line and its ROW.”

Drew explained, “When the SIEAERO equipped helicopter is flying, it acquires about 12,000 high-resolution images for every kilometer flown. One of the major advantages of the SEIAERO system is a single inspection flight gathers all the data needed for multiple surveys/inspections (i.e., visual, LiDAR, vegetation, and thermal). It’s a more efficient method of surveying than the multiple flights system currently in use today. A single flight saves money, reduces labor hours, diminishes the utility’s carbon footprint, and reduces the hazards involved in inspections.”

Drew continued, “The gathered data is processed using AI/machine-learning analytics software to develop a comprehensive 3D digital twin that identifies each structure, component, conductor, vegetation, etc. Once the twin is complete, it contains a highly accurate representation of the transmission line, ROW, and also the vegetation along and under the conductor. Digital twin technology allows personnel to measure vegetation growth, and simulate extreme events such as trees falling onto a line, and conductor sagging into vegetation under the conductors. They can also identify trouble trees that are poised to cause power outages if no action is taken.”

Applications

According to an article in Forbes, “the future of geospatial analytics is in digital twins.” The sophisticated technology is needed to address a more efficient approach to modern vegetation management. It’s available now and is being adopted by utilities and transmission operators around the world.

Energinet, Denmark’s power system operator announced a five year agreement with Fugro to capture aerial LiDAR and imagery data of its entire power line network that is approximately 1,865 miles (3,000 km) in length. The data will be used to develop a digital twin of the Energinet power system, which will model vegetation growth for clearing and maintenance scheduling.

The German grid operators Schleswig Holstein Netz AG and Bayernwerk Netz GmbH have commissioned Siemens Energy to inspect almost 2,485 miles (4,000 km) of high-voltage overhead lines. The inspection will be conducted by a helicopter equipped with a high-tech multi-sensor system using the "SIEAERO" service concept. The data will be used to create a digital twin of the network infrastructure, including poles, lines, terrain, and vegetation.

Florida Power & Light (FPL) has over 85,000 miles (136,795 km) of power lines that share the ROW with many species of trees and vegetation that grow year-round. FPL partnered with GE Digital to create a 3D digital twin using GE’s AI-based Visual Intelligence Platform using GIS, LiDAR, RGB, and analytics. See T&D World online “Tree Intelligence” (https://tdworld.com/21241763) for details.

Acting or Reacting

Traditional methods of vegetation managements are problematic on so many levels, but that all changed when LiDAR scanning and other remote sensing technologies were adopted on a larger scale. As more sophisticated digital technologies have been integrated into vegetation management platforms they took a quantum leap forward and the advancements have never stopped.

Those using these enhanced systems will allow utilities to move away from a reactive approach to one of being more proactive. Imagine a maintenance budget where vegetation management isn’t the number one line item. That should get a lot of attention from customers, regulators, and other stakeholders throughout the power industry.

About the Author

Gene Wolf

Technical Editor

Gene Wolf has been designing and building substations and other high technology facilities for over 32 years. He received his BSEE from Wichita State University. He received his MSEE from New Mexico State University. He is a registered professional engineer in the states of California and New Mexico. He started his career as a substation engineer for Kansas Gas and Electric, retired as the Principal Engineer of Stations for Public Service Company of New Mexico recently, and founded Lone Wolf Engineering, LLC an engineering consulting company.

Gene is widely recognized as a technical leader in the electric power industry. Gene is a fellow of the IEEE. He is the former Chairman of the IEEE PES T&D Committee. He has held the position of the Chairman of the HVDC & FACTS Subcommittee and membership in many T&D working groups. Gene is also active in renewable energy. He sponsored the formation of the “Integration of Renewable Energy into the Transmission & Distribution Grids” subcommittee and the “Intelligent Grid Transmission and Distribution” subcommittee within the Transmission and Distribution committee.