The utility industry has long had the mission of improving line worker safety. And for good reason - powerline workers rank in the top ten most dangerous professions.

“Electrical shock, flash burns and falls are obvious threats when you’re hanging from a pole only a few feet away from high voltage,” explains Bill McNulty, HD Electric Company’s Technical Director, “But there are more insidious injuries that don’t make the newspapers. For example, powerline workers often suffer musculoskeletal injuries due to the bad ergonomics involved in avoiding electrical hazards. Twisting, bending, ducking…all done with the arms and upper body while the waist and spikes are anchored.”

A Pain in the Neck?

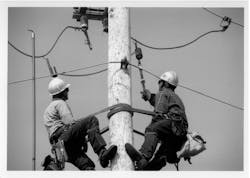

Bill points to an obviously old photo on his desk. “Take a look at these guys! Look at how they have to get into position to read that analog voltmeter on the end of a hotstick. Not only do they need the body of a contortionist, they also must have the eyes of an eagle! Not things you expect in an aging utility work force.”

“Also,” he adds, “Concentrating on a difficult meter read puts the workers in more danger from energized equipment.”

A Better Way!

That old photo, on top of years of field observations, led to informal discussions with several utilities and plenty of brainstorming sessions among HDE instrumentation experts. “Low-weight digital meters were already replacing the old analog sets,“ explains McNulty, “But taking full advantage of larger LED displays and on-board electronics could enable other features, such as phase measurements, to be added.”

That’s when the lightbulb came on for the HDE team – instead of using one hotstick for the meter and the other hotstick for a simple grounding clamp or hook, why not put a display on both sticks connected by a shielded wire communication link?

The safety and work efficiency advantages of dual-display metering would be huge. If one lineman couldn’t easily get into a good position to take a reading, the other one probably could. And four eyes on voltage and phasing measurements provide the kind of redundancy that safety experts and OSHA prefer.

The digital circuitry would also include a peak hold function allowing the worker to focus on the measurement point and read the meter moments later. This safety feature would prove particularly useful when working within tight cabinets and line structures.

Finally, a fully functional prototype was built of what would become the first in a line of Double Vision® Dual Display voltmeters and phasers and the device was presented to customers for initial field testing. Soon after, production units were also being tested by several other utilities.

Why Not Wireless?

Of course, nothing stimulates product improvement and evolution like field experience. And so, several of the utility customers offered something like the following suggestion to McNulty: “If the meters are so smart, why not have them communicate wirelessly? That way we could move the displays further apart without worrying about draping the connecting cable over structures.”

McNulty immediately saw the advantages of a wireless design and set his team to work. Dependable, secure wireless communication in a high-voltage environment is always a challenge. “But that wasn’t the biggest hurdle, “explains Eli Johnson, Electrical Engineer at HDE. “Signal processing was the bigger challenge. To get precision 60Hz voltage and phase information to and from each display required sophisticated timing circuitry.”

What sort of communication link is used - Bluetooth, what? “Nope,” Eli laughs, “We use a proprietary, thoroughly modern digital system with secure packetized data.”

Well, how far does it transmit? Ten feet? Twenty five? “Try a hundred plus,” Eli laughs again. “You can have one guy up a pole measuring line voltage and phase, and have another guy across the street - both having the exact same readout on their digital displays, connected wirelessly. Or you can have the displays showing phase and voltage differences between the two points. Lots of options.”

You could tell that Eli, like most engineers and technicians at HDE, really enjoys his work!

Double Vision® Dual Display Wireless Phasing Voltmeter

Keeps Getting Better!

Recently, HDE engineers revealed another trick up their sleeves – the Double Vision® Dual Display Voltage Indicating Phaser - a wireless, dual-display instrument that doesn’t require a ground connection. Instead, each display measures the capacitive current discharging through the meter housing. “The phase information is very accurate. The voltage will vary by a few percent, depending on surrounding structures,” Eli points out.

Double Vision® Dual Display Voltage Indicating Phaser

“No matter how you cut it, any of the dual-display units are miles ahead of where the powerline instrumentation industry was just a decade ago. And, truth be told, these devices beat anything else on the market today!” Bill agrees.

He adds, “As with other Textron companies – Sherman + Reilly and Greenlee – we have the laboratories and engineering know-how to take an idea and turn it into practical reality. As a result, most product development is originated by a utility approaching HDE with a request for a specific product. But sometimes the HDE engineering team sees a clear opportunity and just runs with it. That’s the case with our Double Vision® Dual Display voltmeters and phasers.”