Fall Protection by Design for BPA Structures

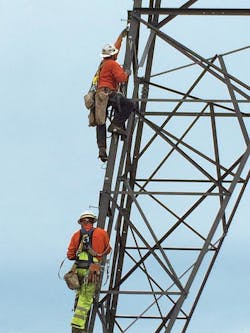

With linemen no longer able to free-climb, electric utilities nationwide have invested in new fall protection equipment for wood poles, modified work practices, and designed and retrofitted towers to meet this new requirement.

To comply with the revisions to Occupational Safety and Health Administration (OSHA) Standard 1910.269, linemen are no longer exempt as “qualified climbers,” and as such, they must be 100% fall protected when working 4 ft or higher above ground.

Three years ago, Bonneville Power Administration (BPA) created a committee of linemen, engineering staff and safety representatives to focus on lattice steel structures, wood poles and rescue techniques. The agency formed the committee after a lineman lost his footing and fell off a transmission tower. Determined to “never relive that day again,” BPA set out to assess and review best practices in fall protection, make recommendations for adoption for both wood poles and steel structures, and work toward 100% fall protection to coincide with the new ruling.

BPA proactively mandated 100% wood fall protection in August 2013, but the company still faced a daunting challenge: ensuring that its 44,000 lattice transmission structures were safe for linemen to climb with their new fall restraint devices.

Implementing Fall Protection for Wood Poles

One of the first actions of the committee was to recommend that BPA adopt a 100% fall protection policy for its 70,000 wood pole structures. BPA then focused on modifying the linemen’s work methods and outfitting them with new fall protection devices.

By August 2013, all of BPA’s linemen were equipped with full-body rescue harnesses and fall restriction devices, which was well ahead of the mandatory deadline.

To implement the program both on time and within the budget, BPA benchmarked with other industry leaders, developed a training program for the linemen and invested in new equipment for the field workforce.

Devising a Plan for Steel Structures

While the wood pole fall protection program involved the purchase of new equipment and the alteration of work methods, the steel structures offered much more complex engineering and design challenges. Because of the complexity of achieving fall protection on lattice transmission structures, BPA initially planned to follow a five-year program. In May 2014, however, OSHA announced the revisions to the standard, which sped up BPA’s plan for implementation.

Four factors, however, presented challenges to BPA: the number of towers on the system, the wide variety of different types of structures, finding solutions for existing structures and designed-in features for new structures. As a result, the company could not take a one-size-fits-all approach.

BPA has more than 300 different tower types including suspension, deadend, transposition and special use. Under the former OSHA rules, qualified climbers were allowed to free-climb. The only time that the linemen were physically attached to the structure was when they reached their desired work position and wrapped a work-positioning belt or skid around a structural member.

In order to comply with the new OSHA ruling, however, linemen can no longer free-climb the transmission structures. As a result, BPA examined the hazards of current work practices, benchmarked with other utilities and developed a multi-stage implementation of new standards, work practices and equipment.

BPA first issued a memo for immediate procedural changes and also developed new work practices and issued new equipment. It also determined that all new 230-kV and 500-kV structures should include “designed-in” fall protection.

Modifying Towers

BPA called upon its Transmission Business Line’s Structural Design Group to retrofit existing structures and come up with design features for new structures. For designed-in fall protection for new towers, BPA had to take into account how the linemen would climb the towers, traverse the structures and get into a secure work position. BPA approved two methods for linemen to scale the transmission towers: step bolt flanges and vertical lifelines.

BPA’s engineers developed flanges for linemen to use with existing step bolts for attachment while climbing. In addition, they also advised that additional holes be added on tower legs for step bolts on new towers so linemen can climb multiple faces of the tower.

For its new transmission tower designs, BPA is working with independent suppliers on climbing systems with permanent, engineered fall protection capabilities such as vertical lifelines and provisions for horizontal movement on the structure through horizontal lifelines. The company also is building in engineered and clearly identified attachment points throughout a structure, incorporating fall protection loads at tower joints, adding horizontal members for workers to stand on and work, and redesigning member bracing schemes.

Scaling Legacy Towers

Retrofitting legacy structures presented a much more difficult challenge for BPA’s engineering department than modifying new transmission towers. While the engineers can design in fall protection for new steel lattice tower structures, they face limited options for retrofit.

For example, some structural members or the connections between them may not meet the fall protection loads. As a result, BPA’s engineers have worked to identify existing bracing points available for anchorage that can withstand the appropriate fall protection loads. Engineers are developing a collection of drawings specific to each tower family that will allow linemen to quickly determine safe anchorage points along with the magnitude and direction of loads they can

accommodate.

BPA is also focused on developing retrofittable climbing systems or methods that will enable linemen to continue to climb towers in a safe and fall-protected manner. In addition to vertical movement on the towers, horizontal movement is a big concern as well. BPA is addressing this using a combination of temporary horizontal lifelines, assuming the structure can withstand the imposed loads, and through the use of pre-identified safe anchorage points during traversing.

As BPA works to meet the new requirements, the company faces the challenge of allowing its linemen to climb existing towers without making costly retrofits and designing fall

protection systems into new structures. Safety is a core value for the company, and BPA is continuously working to modify its structures, personal protective equipment and work practices to protect its field workforce while they maintain and construct new infrastructure.

David O’Claire ([email protected]) is a supervisory engineer for Bonneville Power Administration and is responsible for assisting with the structural aspects of fall protection on lattice transmission towers. A fall protection committee has also been working full-time for the past two years to devise work methods and solutions to work towards OSHA compliance.

Mentioned in this article:

Bonneville Power Administration | www.bpa.gov

Occupational Health and Safety Administration | www.osha.gov