The distribution utility in northern Finland, Rovakaira Networks Construction Ltd., distributes power to 30,000 customers. The population is sparse, being widely spread and clustered in many small villages and hamlets over an area of 28,800 sq km (11,120 sq miles). The medium-voltage and low-voltage distribution network spans 6500 km (4039 miles), and approximately 5% of the network consists of underground cables. The utility has 2500 transformers, all of which are pole-mounted units with capacities ranging from 30 kVA to 200 kVA. Rovakaira has a major challenge to maintain this distribution network to satisfy the low distribution costs and outage targets set by the regulator.

While demanding, this challenge is made worse because much of the distribution area is in the Arctic Circle, which has some of the harshest weather conditions on earth. This includes a recorded lowest temperature of -51°C (-60°F), strong arctic winds, heavy and deep snow for six months of the year, and long periods without any daylight. In these conditions, maintaining a reliable supply of energy to customers can be literally a matter of life or death.

Overhead Line Maintenance

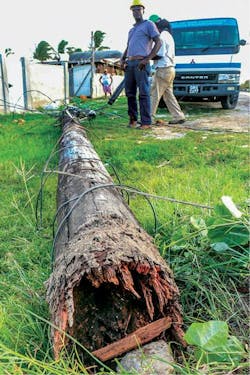

Rovakaira considers the failure of wood poles from ground rot a major problem, as it is more likely to occur during the severe winter conditions because of excessive ice loading and trees falling on overhead line conductors. The average life of wood poles in Finland is more than 50 years. Current utility practice is to replace overhead lines supported by time-expired wood poles with underground cables or, in some instances, with new overhead lines constructed adjacent to roads for ease of access.

Annually, Rovakaira — which experiences an average of 120 overhead line faults — replaces 100 km (62 miles) of overhead line routed through forests and adjacent to roadside verges as well as about 25 km (15.5 miles) of underground cables. All medium-voltage overhead lines are inspected annually in the spring. Line patrols are conducted by field teams using helicopters or snowmobiles.

Pole testing for decay is not a frequent procedure for all wood poles, as testing is limited to wood poles in service for at least 35 years. However, the utility sought a solution to minimize wood pole decay to improve its network reliability, reducing long-term maintenance and repair costs in addition to reducing the need for overhead line fault repairs in adverse weather conditions.

To satisfy the requirements of both reduced long-term maintenance costs and improved network reliability, Rovakaira considered a range of options that included ground line barrier sleeves to prevent ground rot in its wood poles. The use of composite ground line barrier technology can typically double the pole life, thus greatly reducing costs and preventing early failures also while improving system reliability.

In 2014, before deciding whether to switch from a wood-pole preservative treatment to an environmentally friendly yet potentially less-effective copper-only wood pole preservative, Rovakaira wanted to better understand the types and causes of pole decay. The utility would then be in a good position to establish the criteria to evaluate the different barrier sleeve products on the market to ensure it selected the best solution to meet the utility’s needs.

Ground Line Decay

Almost all wood poles erected by distribution utilities to support overhead line conductors are subject to ground line decay. The decay, combined with high mechanical loading, results in the ground line being the normal point of failure for wood poles.

For pole decay to occur, the following criteria must be present:

• Oxygen

• Nitrogen

• Wood-decaying fungi

• Moisture content greater than 25%

• Temperatures above 10°C (50°F)

• Depleted preservative protection.

Considering the pole-erection procedure in more detail, it is evident the deeper the pole is in the soil — typically 30 cm (12 inches) or more below ground level — the factors necessary for decay to occur are greatly reduced or not present. This means the risk of decay below this level is nonexistent.

The ground line section of the pole is surrounded by all the factors necessary for decay to occur; the only defense against decay and pole failure is the protection offered by the preservative impregnated into the pole by wood pole suppliers. However, the ground line section is subjected to major variations in moisture content throughout the year as ground level soil becomes seasonally wet and dry. The net effect of these small changes results in long-term depletion of the wood preservative, making the pole vulnerable to attack over time by the wood-decaying fungi present in the soil at the ground line section.

Two types of decay cause ground line failure in utility wood poles, namely, soft rot and core rot. Soft rot is where the outer part of the pole is attacked by decaying organisms present in the soil; core rot (or brown rot) attacks and decays the core of the pole.

Establishing the Criteria

Based on the research, it was evident to Rovakaira that using additional protection against decay on the vulnerable ground line section of the pole would help to reduce outages from pole failures while significantly extending pole life, resulting in excellent cost savings. Rovakaira, in partnership with the approved pole supplier, established the following key performance requirements that a barrier system would need to meet to be effective:

• Protect the vulnerable ground line section of the pole.

• Exclude all factors that may cause decay, including oxygen, decaying organisms, nitrogen and, most importantly, moisture.

• Retain the preservative within the wood pole to maintain secondary protection over time.

• Be nontoxic to ensure environmental concerns could be satisfied beyond the requirements of the European Biocidal Products Directive.

• Be easy to apply and have a low additional pole cost.

• Be sufficiently robust for the sleeved pole to be transported from the pole supplier to the site and for installation to be completed without damage issues that could compromise the performance of the barrier system over time.

• Allow the utility to continue following its standard pole test procedures.

• Be designed to withstand installation in stony ground conditions using dig and backfill installation equipment

• Be independently tested and proven in use.

Evaluation of Products

The pole supplier investigated the available barrier sleeve options and their suitability for ease of application and in-service protection. These included the following alternative products:

• Heavy-duty open-topped bags lined with a metal barrier film, a U.S. product that slides over the base of the pole and is taped to the pole above ground level.

• A German system whereby metal foil is wrapped around the pole and then covered with a heavy-gauge plastic sheet, which was wrapped over the metal foil and heat shrunk in situ.

• A U.K. product with a heat-shrink thermoplastic ground line sleeve lined with a heat-applied thermoplastic bituminous sealant.

The first two products failed to seal to the pole surface satisfactorily, raising concerns over the ingress of water, oxygen, nitrogen and decaying organisms through the gap between the sleeve and the pole surface. Also, although the bag system was tough, there were concerns the bag would be open to water ingress if punctured.

The third and final product, manufactured by Postsaver Europe Ltd., satisfied all the criteria. Once heat was applied, the bituminous liner inside the outer thermoplastic heat-shrink sleeve melted to form a tough watertight seal to the pole surface. This seal effectively lowers the entry point for moisture to the pole, keeping the zone inside the sleeve relatively dry — below the 25% level when decay may occur. Even if punctured or damaged, the area of wood exposed to water ingress that can lead to decay is limited to the damaged area only, unlike the other systems. This product also proved to be easy to apply to the pole and was the lowest-cost option of the three products evaluated.

Initial Trials

Rovakaira implemented initial trials in 2011 using the Polesaver composite barrier sleeve system and bituminous ground line sleeve system. The pole supplier applies the sleeves to the poles prior to delivering them to the utility, which increases the cost of the pole by 20%. However, Rovakaira expects the service life of the sleeved wood poles to be increased by some 15 years or more. The initial trials proved promising, apart from experiencing some problems that resulted in low-level damage to the sleeves when a backhoe excavator was used to install the polls. This problem was soon overcome with some plant operator training.

Subsequently, Rovakaira now has installed more than 4000 poles fitted with Polesaver sleeves successfully. Based on the relatively low unit cost, reduction in outages and estimated overall cost savings, Rovakaira has adopted this form of ground line protection as the standard for all its pole replacements and on poles erected for all new overhead lines.

Hannu Lehtinen is president and CEO of Rovakaira Networks Construction Ltd., with overall responsibility for the network including maintenance. Lehtinen has been in his current position for eight years. With extensive long-term experience of treated wood poles used in both distribution and telecom utility applications, he has gained an in-depth knowledge on the service life and performance of wood poles.