Alternative Design Measures Limit Pole-Top Fires

In common with utilities around the world, parts of Eskom’s medium-voltage distribution network in South Africa suffer from pole-top fires, adversely impacting reliability. A.K. Persadh studied this problem in the KwaZulu-Natal, South Africa, province as part of his master’s thesis in October 2007. He estimated approximately one fire occurred per 1000 km (622 miles) of 22-kV network annually.

While this might not seem like a large number, every occurrence has the potential for severe consequences that extend far beyond network reliability. Pole-tope fires can result in low-hanging conductors that are energized yet intact and not in contact with any grounded object. This type of situation is not detectable today in a practically viable way, and certainly not on a large, distributed network like Eskom’s.

Pole-Top Fires

The reason for pole fires, sometimes referred to as pole-top fires, is leakage current flowing over wet and polluted overhead line insulators, a well-known phenomenon in the electric distribution industry. However, the approach taken to mitigate the problem varies significantly in different regions of the world. Eskom has developed and adopted an approach that has been tested in a natural high-leakage current environment and can be implemented easily in the field. Preliminary studies also took into consideration other causes of wood structure fires and methods to minimize them.

Prime Conditions

The location of the wood-pole structures, primary atmospheric conditions and surface condition of overhead line insulators in terms of the degree of pollution are all contributing factors linked to pole-top fires. Generally, the conditions that can result in leakage current are as follows:

- The surface of one or more of the overhead line phase conductor’s insulators has surface pollution.

- The polluted insulator gets lightly wet from mist, fog, drizzle, light rain or condensation. Conversely, heavy rain can help to reduce the risk of pole-top fires because it cleans the insulators, reducing the buildup of surface pollution.

- Wet and polluted insulators offer a conductive surface, resulting in leakage current.

- The leakage current finds its way into the interior and/or onto the surface of the wood pole or cross arm of the distribution structure.

- Arcing results, leading to tracking on the surface of the wood, which can be ignited.

Mitigation Measures

Electric utilities have numerous mitigation measures at their disposal, including engineering design like electrical bonding and earthing coupled with or without operational interventions such as insulator washing and leakage current detection.

Bonding unenergized pole-top hardware together diverts leakage current away from the wood sections of the overhead line support. The bonding is earthed by a down-running earth wire. This wire includes an air gap provided by the wood pole in series with phase insulators. The air gap effectively reduces the number of power interruptions from lightning, as induced lightning surges rarely cause the line to flash over at the higher insulation level provided by the air gap.

For new overhead line construction, the use of composite phase insulators with at least a 31-mm/kV (1.22-inch/kV) specific creepage is recommended to limit the magnitude of leakage current. On existing lines, porcelain products with the same specific creepage specification may be acceptable for use as phase insulators.

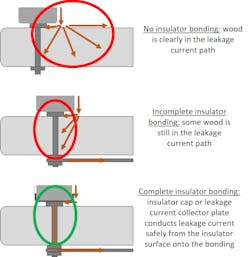

All phase insulators must have suitable conductive end fittings to ensure leakage current is safely conducted from the surface of the insulators onto the bonding. Post insulators must be capped, and uncapped insulators need a leakage current collector plate to divert the leakage current to the bonding.

Steel cross arms may be used instead of wood cross arms, eliminating the problem with burning cross arms. Eskom uses steel cross arms extensively, but there are trade-offs with material and labor costs. Steel cross arms cost significantly more than wood cross arms, but they are also relatively simple to install and more robust. Steel cross arms also have issues related to vibration that causes nuts to loosen, steel-weld quality controls and corrosion mitigation. The utility has found steel cross arms achieve the same purpose with respect to pole-top fires as bonded wood cross arms, provided that all mitigation measures are correctly implemented.

Verifying Effectiveness

The effectiveness of these alternative mitigation measures can be verified in two ways: by investigating pole-top fires in the field and testing the measures in a highly polluted environment.

Eskom achieved the former through a targeted field investigation of structure fires. For all structures with pole-top fires in which the cause could be conclusively verified, the utility found those structures did not meet at least one of the mitigation criteria. For example, the overhead lines were constructed before bonding was introduced.

Eskom’s Koeberg Insulator Pollution Test Station (KIPTS) served as the high-pollution test environment, as it is located in a natural pollution environment close to the high-water mark of the Atlantic Ocean on South Africa’s West Coast, near Cape Town. This site was chosen for testing because of its severe pollution levels and the power and measurement infrastructure were already in place, as the test station was constructed specifically for insulator testing. Six wood-pole test structures were erected and each of the different insulator technologies and bonding arrangements were evaluated. The results of the tests verified the effectiveness of each of the proposed mitigation measures.

Other Wood-Pole Fires

Pole-top fires are generally restricted to overhead distribution lines and lower-voltage overhead transmission lines supported by wood poles. At higher voltages, capacitive rather than conductive effects dominate the performance of high-voltage overhead transmission lines.

Wood-pole structures installed to support overhead distribution lines are also subject to burning for reasons other than leakage current flow. For example, a phase conductor or jumper could get disconnected from its insulator and end up lying on the cross arm, a phase conductor or jumper could clash with a pole or stay in high wind, or a failed insulator could conduct excessive leakage current.

Lightning flashover occasionally causes a wood-pole structure to burn. If the structure is bonded and earthed correctly, then the fire would start on the pole at the insulation coordination gap (that is, at the location of flashover across the pole). However, the risk of poles burning in this way is lower than the risks mitigated by inclusion of the gap.

Each of these fires can be mitigated by addressing the cause, such as engineering designs where problems are encountered, ensuring overhead line hardware is adequately specified and scheduling maintenance inspections to detect loose conductor ties and brackets.

Engineering Philosophy

Many of the world’s overhead distribution line networks are routed in harsh environments, such as high levels of lightning or pollution. Measures can be introduced at the design stage, prior to construction, or retrospectively to improve the performance and safety of these distribution networks in high-pollution areas, where networks are more prone to pole-top fires. These fires are caused by leakage current flow produced by the light wetting of pollution deposited on phase insulators.

Acknowledgments

Several Eskom colleagues, past and present, assisted with various aspects of this work and are gratefully thanked. The authors would like to especially acknowledge the contributions of Mikhuva Ntshani, Keneilwe Thejane, Thamsanqa Mvayo, Rob Watson, Hendri Geldenhuys, Richard Evert and Johan Neethling.

Andreas Beutel ([email protected]) holds bachelor’s, master’s and Ph.D. degrees in electrical engineering from the University of the Witwatersrand, South Africa. He is currently chief engineer at Eskom Holdings SOC Ltd., South Africa. His research interests include electrical distribution, insulation and safety, as well as lightning and surge protection. Dr. Beutel is a registered professional electrical engineer in South Africa, a Chartered Engineer in the UK and a Fellow of the South African Institute of Electrical Engineers.

Bruce McLaren holds a national diploma (electrical), a graduateship in electrical distribution from the City and Guilds of London Institute and a post-graduate diploma in project management. He has recently retired as senior technologist at Eskom Holdings SOC Ltd., South Africa. McLaren’s research interests include medium- and low-voltage electrical distribution, including applied insulation, safety and lightning mitigation. He is a registered Professional Electrical Technologist in South Africa and a member of the South African Institute of Electrical Engineers.

About the Author

Bruce McLaren

Bruce McLaren ([email protected]) holds a national diploma in electrical, a graduateship in electrical distribution from the City and Guilds of London Institute, and a post-graduate diploma in project management. He is a senior technologist at Eskom Holdings SOC Ltd. McLaren’s research interests include medium- and low-voltage electrical distribution, including applied insulation, safety and lightning mitigation. He is a registered Professional Electrical Technologist in South Africa and a member of the South African Institute of Electrical Engineers.

Andreas Beutel

Andreas Beutel ([email protected]) holds BSEE and MSEE degrees as well as a Ph.D. in electrical engineering from the University of the Witwatersrand, South Africa. He is currently chief engineer at Eskom Holdings SOC Ltd. His research interests include electrical distribution, insulation and safety, and lightning and surge protection. Dr. Beutel is a registered professional electrical engineer in South Africa, a Chartered Engineer in the UK and a Fellow of the South African Institute of Electrical Engineers.