Making Transmission Cool: A New Look at High-Temperature Superconductors

It’s spring, and I sure have been looking forward to the end of winter. The temperature is rising, the tulips are getting taller, and my virtual inbox is flooded with news of technological developments popping up on the power grid. I always look forward to the spring bumper crop of press releases, and it has been a busy winter. One from Con Edison felt special because it fit nicely with my January 2023 editorial about growing pains in the supply chain.

That editorial focused on how the supply chain is impacting many utility solar projects and customer projects are becoming more important. Con Edison reported that its customers made 2022 a record year with solar installations. It completed 9,600 solar projects with a capacity of 89 megawatts (MW) in 2022. Con Edison went on to say when 2022 was combined with previous years, its customers have installed over 487.32 MWs behind-the-meter. It’s amazing what a utility and its customers can do when they work together!

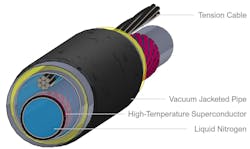

Another release had a personal link for me. It was from a cryogenic company, VEIR. It was about its latest developments in high temperature superconductors (HTS). Cryogenics is a fascinating technology and the HTS area offers many applications relevant to the power delivery system. They range from energy storage to power delivery and a lot of other topics that are improving the power grid.

HTS Memories

As I read this release I thought about a HTS project I had been involved with several decades ago. It was one of those “never been done before” projects and I could never resist that type of challenge. If you’re not familiar with cryogenics, superconducting technology is one of those technologies that has been around for a long time. However, it needed materials science to catch up with the theory before it could make the jump from the laboratory and to the power grid.

The development of HTS materials was that breakthrough. Materials were discovered that allowed superconducting to take place near the boiling point of liquid nitrogen, –320.4ºF (– 195.79ºC), rather than near absolute zero. And that’s as deep as I’m going into the physics. It was dubbed high temperature superconducting, and a lot of demonstration projects popped up in the power industry.

My exposure came about when a HTS cable manufacturer contacted the utility I worked for with a proposal. They wanted to modify the utility’s back-to-back HVDC (high-voltage direct current) converter station with HTS cabling inside the valve hall. The HTS cables would be an HVDC transmission line running between the two sections of the back-to-back converter.

HTS Today

With that in mind, this release got me thinking about cryogenics once again. I wanted to find out more about what was taking place, so I talked with VEIR’s chief executive officer, Tim Heidel about their unique approach to HTS cabling. He explained, “VEIR’s system allows for higher currents at lower voltages, which can result in smaller rights-of-way. It could provide 5 to 10 times the capacity of conventional transmission lines.”

When asked how the VEIR system compared to other HTS methods, Heidel said, “Traditional HTS cabling uses underground closed-loop systems. VEIR uses an open system with evaporative cryogenic cooling to keep the superconducting material cold for its entire length. This is a simpler system that is lighter and can be used for overhead transmission.”

We continued our discussion. Heidel said, “In December 2022, VEIR completed an end-to-end demonstration of its core technology. A 100-foot (30 meters) span of VEIR’s cable system was suspended on steel towers in the lab. The test span was successfully operated at 4,000 amperes – a first ever for an overhead superconducting transmission line.” Heidel and I promised to stay in touch and see where this new application will take HTS overhead transmission in the future.

With highway and railway rights-of-way being shared with transmission lines, reducing the space required for those lines and increasing their capacity is a critical element in renewable integration. HTS is poised to be a major contributor for these characteristics!

About the Author

Gene Wolf

Technical Editor

Gene Wolf has been designing and building substations and other high technology facilities for over 32 years. He received his BSEE from Wichita State University. He received his MSEE from New Mexico State University. He is a registered professional engineer in the states of California and New Mexico. He started his career as a substation engineer for Kansas Gas and Electric, retired as the Principal Engineer of Stations for Public Service Company of New Mexico recently, and founded Lone Wolf Engineering, LLC an engineering consulting company.

Gene is widely recognized as a technical leader in the electric power industry. Gene is a fellow of the IEEE. He is the former Chairman of the IEEE PES T&D Committee. He has held the position of the Chairman of the HVDC & FACTS Subcommittee and membership in many T&D working groups. Gene is also active in renewable energy. He sponsored the formation of the “Integration of Renewable Energy into the Transmission & Distribution Grids” subcommittee and the “Intelligent Grid Transmission and Distribution” subcommittee within the Transmission and Distribution committee.