A Practical Overview of CT Saturation Causes and Mitigation Techniques

This article provides a simple explanation of what CT saturation is, what causes it, and what you can do about it. For a more thorough, technical treatment of this topic, refer to the paper, “Beyond the Knee Point: A Practical Guide to CT Saturation.”

How Do CTs Work?

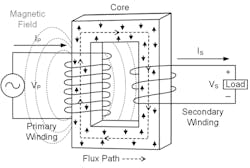

Like any transformer, a CT consists of a primary winding, a secondary winding, and a core (see Fig. 1). When an alternating current flows on the primary winding (primary current, IP), it generates an alternating magnetic field in the core. This field, in turn, induces an alternating current on the secondary winding (secondary current, IS) that is proportional to the primary current. This is how CTs scale current values to meet the needs of relays and other measurement and control devices.

What Is CT Saturation and Why Should I Care?

To better understand CT saturation, think of the iron core of the CT as being made up of a huge number of tiny, molecular magnets that are randomly arranged. The magnetic field created by the primary current causes these magnets to line up in the same direction as the field. This aligning of the magnets with the magnetic field produces magnetic flux, a measurement of the amount of magnetic field in a given area. A higher magnitude current generates a stronger magnetic field, which causes the magnets to align more fully and increases magnetic flux. This process of the magnets changing their alignments is what induces the current on the secondary winding.

Normally, the molecular magnets in the CT begin randomly oriented, align in one direction for the first half of the cycle, and then align in the opposite direction for the second half of the cycle. Because there are always magnets changing their alignment, secondary current is continuously induced in proportion to the CT ratio. However, if a situation occurs in which all the magnets align in the same direction, the CT core becomes saturated, a state also known as maximum flux density.

Since the change in the alignment of the magnets induces secondary current, when there are none left to change direction (that is, the core becomes saturated), the current on the secondary winding drops to zero, as shown in Fig. 3. With no current on the secondary winding, the CT can no longer provide accurate current information to measurement and control devices, which can lead to relay misoperation.

What Causes CT Saturation?

There are two main types of CT saturation: symmetrical and asymmetrical.

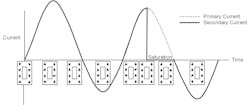

Symmetrical saturation is caused by a primary current that is too large for the CT core to handle for a given load or burden. An example is shown in Fig. 3 that assumes a CT ratio of unity (that is, 1:1). The primary current causes a strong enough magnetic field to align the magnets in the first half cycle. When the CT runs out of magnets to realign, the secondary current drops to zero.

Once the primary current enters the negative half of the cycle, the magnets begin aligning in the other direction and secondary current is produced once more. However, because of the strength of the primary current, the magnets all align in this direction and the secondary current drops off again.

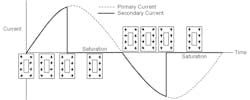

Asymmetrical saturation occurs as the result of dc offset in the primary current. This offset causes the current wave to no longer be symmetrical around zero, as illustrated in Fig. 4. This results in one half of the cycle being larger than the other. Because the amount of magnetic flux created in the CT is proportional to the area under the curve, this asymmetry causes more flux to accumulate in the direction of the larger half cycle than can be reset by the smaller half cycle. This extra flux accumulates until the CT saturates.

Because asymmetrical saturation does not require a high primary current, it can take several cycles to occur, unlike symmetrical saturation which normally occurs in the first half cycle after a fault. Note that low levels of saturation can be much harder to detect than those depicted in Fig. 3 and Fig. 4.

What Should I Do About It?

The simplest solution to CT saturation is to select a CT with high accuracy class. However, higher-rated CTs are sometimes not viable because of physical limitations such as restricted spaces.

Another option is to reduce the CT burden. Halving the burden by adding another set of CT cables in parallel has the same effect as doubling the CT accuracy class. Using CT taps, if available, to effectively double the turns ratio has the same effect as quadrupling the accuracy class.

Relay protection algorithms can also be used to desensitize or delay relay operation during CT saturation, though they are no substitute for selecting the appropriate CTs in the first place. If you plan to use such algorithms, it is recommended that you test them in a digital simulator prior to deployment.

Conclusion

Even the best protection and control devices are only as good as the information they have to act upon. Choosing the right CTs and taking other steps to avoid saturation are essential to giving your devices the information they need to operate reliably and protect your electric power system.

Reference

About the Author

Brad Heilman

Brad Heilman, P.E., has a BSEE degree from the South Dakota School of Mines and Technology. From 1990 to 1997, he was employed as a system protection engineer for Black Hills Power and Light. His utility work included transmission line and generator protection, power plant and substation commissioning, and SCADA system upgrades. In 1997, he joined Schweitzer Engineering Laboratories, Inc. as a field application engineer supporting customers in Arizona, California, Montana, Wyoming, Utah, North Dakota, Nebraska, Nevada, Idaho, and South Dakota. He is an IEEE member and licensed professional engineer in the state of South Dakota.

Ryan Urie

Ryan Urie received a BA in English from the College of Idaho in 2004 and an MS in bioregional planning from the University of Idaho in 2010. He joined Schweitzer Engineering Laboratories, Inc. (SEL) in 2013 as a technical editor. In addition to editing numerous technical papers, application guides, articles, and presentations, he has written several articles, white papers, and case studies for the SEL.