Some days, a picture is worth far more than a thousand words. When effective communication is needed, imagery can play an important role. However, in many instances, pictures are not enough. For electricity providers, plans and drawings familiar to engineers and technicians may be confusing to customers, laypeople or even in-house workers, which can lead to lack of understanding of a design, project or maintenance task. The result can be repeat site visits, rework, compliance issues, customer complaints and cost overruns — all of which easily could have been prevented through accurate and effective communication, context and understanding.

Looking to solve these challenges and more, the American Electric Power (AEP) distribution engineering best practices group began considering augmented reality (AR) technology in the spring of 2018 as a possible solution to minimize discrepancies. Focused on its mission of incorporating the use of existing and emerging technologies to create and improve safe, cost-effective designs and efficient workflow practices, the best practices group supports approximately 800 distribution engineering technicians and engineers who use line design applications to build and maintain the utility’s distribution network. The group’s work also involves structural analysis, secondary electrical analyses, cable-pulling studies and facility design.

These activities require knowledge of local site conditions and staking for distribution lines and facilities. In addition to marking the location of proposed installations, staking supports the process of in-field review and approval by customers and landowners who may be affected by new poles and lines being placed on their property or in a right-of-way near or through their property. Typically, staking jobs are completed in a single visit, but in some cases, two or three visits may be needed to ensure everything is completed properly. For complex jobs, even more site visits may be required.

Another challenge in design and staking jobs is in placing and replacing missing stakes. Back in 2018 and years prior, it was not uncommon for this to occur as often as six or more times in a single job at AEP. As a result, when line construction crews would arrive on a job site and stakes were missing, it could take 30 minutes to 1 hour (or more) for an engineering technician to arrive and re-stake the job site. A focus on reducing the resourcing and costs associated with staking workflows was an important factor in AEP’s decision to consider using AR technology as part of its best practices program.

Distribution Applications

Introducing AR into AEP design and construction workflows to improve process was gradual. It first began in July 2018 at the annual AEP Survey Seminar in Columbus, Ohio, U.S., with an on-site overview and demonstration of Trimble SiteVision for Utilities AR technology. Seeing the possibilities, AEP kicked off an early adoption AR project with Trimble Inc. in the fall of 2018.

A training event on the AR solution was held in February 2019 at AEP’s Newark Service Center in Ohio. About 10 AEP Ohio Operating Company engineering technicians and a line crew supervisor received hands-on training on how to use AR technology. This included using AR for visualizing AEP data and 3-D models, such as the placement of poles and visualization of property lines in the field.

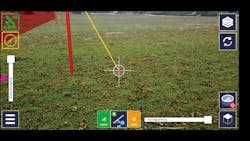

What these AEP training participants quickly discovered was how AR technology could superimpose 3-D utility models against real-world views to enable accurate visualization of proposed and existing utility features, on-site and in real time. They also realized using AR could greatly improve communication and coordination with customers and crews by replacing 2-D drawings with on-site 3-D visualization of planned structures, line designs and other activities.

They also identified a stake-less workflow using AR, which could address the common issues related to missing stakes. It became clear AEP engineers and construction crews could use AR as a tool to streamline the customer review process and confirm the placement within about 1 inch (25 mm) of poles, lines and other utility facilities without the need for wooden stakes.

AR Rollout

In June 2020, 10 AEP engineering technicians and line crew supervisors in the AEP Ohio Operating Company received full production training of the AR product as part of the initial rollout of the technology. The Trimble AR technology runs on smart mobile devices and connects to a Trimble global navigation satellite system (GNSS) antenna that provides 3-D positions in the field accurate to 1 inch or less. The high-accuracy positioning capabilities coupled with AR technology is crucial to AEP workflows, as it ensures accurate placement and representation of planned designs at the right locations in the field.

The smart mobile device is mounted on a lightweight 1.24-lb (0.56-kg) handle that incorporates a Trimble GNSS antenna and an electronic distance measuring (EDM) tool, to measure design features and distances. The mobile hardware AR platform makes for safe and easy portability of the AR technology and enables extended use outdoors with engineers and line crew supervisors in the field.

Since the initial AEP deployment of AR technology in June 2020, engineering technicians and line crew supervisors already have implemented AR technology into their design and construction workflows. For example, instead of a customer just looking at a design on paper, a dot on a map or a stake in the ground, AR has given context to the location of the stake (through visualization of a utility pole and line) and what it would represent on a customer’s property within about an inch of location accuracy. Customers, line construction crews, technicians and inspectors have more context and a better understanding of planned designs and any clash with natural or man-made structures when visualized in AR and in 3-D.

Also part of the AR rollout at AEP was the development of a workflow to minimize any impact on design teams by ensuring a smooth connection between their existing field design system — Distribution Design Studio (DDS) from Geospatial Innovations Inc. — and the Trimble AR solution. Once engineers complete their designs in the DDS application, they use an existing process to convert the designs into a keyhole markup language (KML) format. The designs then are placed into a designated folder in a Cloud-based collaboration tool for organizing and managing design files so they can be accessed in the field. From there, the engineers download the model into the AR application and, while on-site in the field, check and validate the designs for real-world placement and measure distances of the designs to nearby natural or man-made objects and vegetation. Additionally, if there are any updates or changes to the designs, notes are added to the design files and office staff can access the design files from the Cloud-based collaboration tool and make any necessary design or job changes.

Based on its current AR deployment with engineering technicians and line crew supervisors, AEP estimates it can reduce repeat site visits by 50% as well as engineering and construction rework by 25%. With AEP generating approximately 70,000 design and construction jobs every year, the utility has calculated a favorable ROI on both technology purchases and annual recurring AR subscriptions, occurring within a year of initial purchase and after three months of use each calendar year, respectively.

While further AR technology rollout for distribution applications has been slowed by the COVID-19 pandemic, AEP has plans in place to deploy the AR technology to even more engineering technicians and line crew supervisors in other locations throughout the AEP system.

Transmission Applications

As part of a separate rollout of AR technology on the transmission side of the utility, AEP transmission team leadership engaged in a project with Trimble in 2019 to visualize Power Line Systems’ PLS-CADD transmission line design blowout models. In-field visualization of the line designs have enabled AEP design engineers to compute line clearance related to the effects of temperature, wind and sag on overhead lines (especially on 345-kV or 765-kV lines) to show crews and customers what happens to the wires during periods of high winds or maximum sag and encroachment of vegetation that needs to be cut back.

This can be difficult to convey in the field with a customer on a nice day when wires are up and trees need to be trimmed. The AR tool enables AEP foresters, crews and customers to see in the transmission blowout which trees are impacted and pose risks under a variety of potential weather conditions. As a result, gaining customer understanding and buy-in on trimming is easier and compliance with regulatory clearance requirements more effective.

Similarly, AEP uses AR technology as part of its current work in corridor planning. After creating georeferenced models for towers, poles and other facilities, AEP staff in the AEP Ohio Operating Company routinely go on-site and visually compare line designs with real-world in-the-field conditions. Using AR in this case, AEP engineers detect design clashes with AEP rights-of-way, existing man-made structures (such as roads, bridges and buildings) and naturally occurring obstructions (trees, rocks, rivers and ponds) well before construction begins and crews and equipment arrive on-site. Also, in areas where underground utilities have been accurately mapped within the AEP Ohio network, as-built data can be added to the AR data set and displayed along with the existing and planned structures.

Extending AR Technology

AEP has identified and explored other applications for AR, such as for electric vehicle (EV) charging station, streetlight, and meter placement use cases and workflows. As part of a smart city initiative with the city of Columbus and a grant from the U.S. Department of Energy, AEP is engaged in a project to deploy hundreds of EV charging stations, including more Level 3 charging stations for EVs throughout the city. Because Level 3 charging stations require additional infrastructure (specifically large pad-mounted three-phase transformers and meter boxes), it is important to provide a complete picture of how a charging station will affect the placement area.

By creating standard models of the possible transformers, charging pedestals and other fixtures, AEP staff is using AR as part of walk-throughs with key stakeholders of an EV charging station site and collaborating on plans to mitigate the visual impact as well as confirm location and placement. For example, in planning outdoor commercial spaces, AEP staff uses AR to check the location, wheelchair accessibility (for compliance with the Americans with Disabilities Act), and aesthetics of transformer, meter boxes and other distribution assets in relation to walkways in retail areas or restaurants with outdoor patio dining areas.

AEP staff also have identified and tested an AR use case related to exterior area lighting, streetlight and floodlight illumination. Once the COVID-19 pandemic subsides and the utility returns to a more normal operating environment, AEP has project plans in place for streetlights and area lighting placement whereby AR will be used for confirming height above ground, light rotation, tilt and pitch. The project also consists of adding light manufacturer photometric data, which will be integrated into the 3-D streetlight models and visualized in the Trimble AR system. When this information is displayed in AR in the field, data on intensity and directional lighting will enable key stakeholders to see how a proposed light can have the desired effect — something that just cannot be shown on paper.

Additionally, AEP plans to use AR technology for electric meter visualization and placement confirmation. For example, AEP staff could work with restaurant customers on outdoor seating plans to show where a meter bank would go, confirm placement, and check compliance with local codes and clearance. The same could be performed with residential customers who are adding or moving a meter on their home.

Beyond Power Lines

Looking forward, AEP sees widespread possibilities for AR applications in its operations. One opportunity lies in tracking underground electric assets as well as those of other utilities. As georeferenced data sets of assets expand, the location of buried pipelines, water, sewer and communications infrastructure can be displayed to users in the field. AR may also can be used in damage assessment. Features can be captured in their original condition and then compare conditions following an incident that results in damage or displacement.

As the adoption of AR technology continues to expand into other areas within AEP and each new application and use case, there will be more opportunities and challenges. It is difficult to overstate the potential for AR technology to provide important results in increased efficiency, safety and cost management. For now, AR technology will continue to give AEP’s teams a simple yet powerful assist in getting their work done.

Matt Shellenberger is a registered Professional Engineer in Ohio and a staff engineer at American Electric Power. Based in Columbus, Ohio, he leads the distribution engineering best practices group and serves on IEEE National Electrical Safety Code Subcommittee 5, focused on overhead lines strength and loading.

About the Author

Matt Shellenberger

Matt Shellenberger ([email protected]) is a registered Professional Engineer in Ohio and a staff engineer at American Electric Power. Based in Columbus, Ohio, he leads the distribution engineering best practices group and serves on IEEE National Electrical Safety Code Subcommittee 5, focused on overhead lines strength and loading.