ABB and its predecessor companies have consistently stood at the forefront of the manufacturing and development of commercial transformers ➔ 1. As transmission distances from remote generation increased, the transmission voltage had to rise to keep losses down and to reduce the number of lines needed in parallel. In the early 1950s, Sweden commissioned ASEA for the world’s first 400 kV transmission system with a length of about 1.000 km and 500 MW capacity. This breakthrough in extra high voltage (EHV) transmission set a new standard for Europe.

1 Pulling the Gotland cable ashore in 1950. The power link connected the island to Sweden's mainland power grid, supporting the development of the island's economy

In the latter part of the 1960s, the Canadian province of Quebec followed suit. Similar to the situation in Sweden, it too had abundant hydropower yet large geographic distances between the power source and industrial areas. Together, the power company Hydro-Quebec and ABB developed a 735 kV EHV transmission system. In the United States, large thermal power plants, from which the power had to be distributed over long distances, were also being built. This resulted in the introduction of a 765 kV system. In the early 1970s, the Tennessee Valley Authority commissioned its first 1,200 MVA power plant at Cumberland, Tennessee. ABB built the first generator step-up transformers (rated 420 MVA) in a single-phase design.

These transformers represented a technical breakthrough in terms of power capacity on one wound limb.

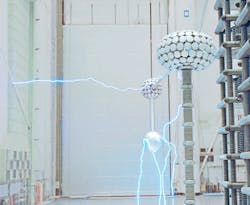

At the same time, ABB entered a development program together with American Electric Power (AEP) aiming for the highest technically feasible AC transmission voltage. For this purpose, ABB built a full-size single-phase network transformer for 1,785 kV, rated at 333 MVA. This test transformer was installed and successfully operated at the research facility until completion of the research program ➔ 2. Similar development programs occurred in other countries. For example, a full-size ABB transformer and shunt reactor was built in Italy for 1,000 kV and installed at the ENEL test station Suvereto.

2 The 1,785 kV ultrahigh voltage transformer installed at the USAEP-ASEA test station (USA)

During the last few years the need for even higher capacity long-distance transmission has resulted in renewed interest in ultrahigh voltage alternating current (UHVAC) voltages in the range of 1,000 to 1,200 kV AC in China and India, and the development of 800 and 1,100 kV ultrahigh voltage direct current (UHVDC) has resulted in ABB emerging as a major player in pushing transformer technology to new levels.

The TrafoStar technology platform

In August 1987, the Swedish ASEA and the Swiss BBC companies merged and formed ABB. Shortly afterward, ABB merged the transformer manufacturing parts of Westinghouse in the United States, which also included the former General Electric transformer technology, as well as Ansaldo in Italy and several Spanish factories. National Industri in Norway and the Finnish company Strömberg had become part of ASEA just before the merger. Together, these companies contained a very large portion of all the power transformer knowledge and experience in the world.

After the merger, a number of task forces and research and development groups were established to evaluate the experience and best practices from a wide range of previously independent transformer manufacturers. Major objectives were lower costs, shorter production times, higher quality and reduced test room failures. These objectives have remained the main focus for ABB's continued transformer development. As a result, ABB succeeded in unifying its technology into a common platform, TrafoStar, and today it offers products with the same high standard of quality wherever in the world the transformers are manufactured ➔ 3.

3 TrafoStar

The TrafoStar technology platform includes the following key ingredients:

- Common design rules based on experience from all ABB predecessor companies

- Common design system and design tools

- Common manufacturing processes, equipment and tools

- Common quality and failure analysis systems

- Common feedback and continuous improvement programs

- Common training and education systems

ABB launched the common concept, Trafo- Star, more than 15 years ago, with integrated engineering tools, manufacturing accuracy and major suppliers with common material specifications, testing and quality management system. This concept is now used for large power transformers in all ABB plants globally. Since the inception of TrafoStar, more than 15,000 power transformers have been produced; of these, 2,000 units are very large generator step-up (GSU) transformers and intertie transformers. More than 1,000 power transformers of more than 60 MVA rating are produced every year. This unique business concept has allowed ABB to amass design and manufacturing experience in a truly global way, for continuous process improvement ➔ 4.

4 High-voltage direct current (HVDC)

By the early 1950s, developments in current conversion technology led by ASEA, ABB's Swedish forerunner, enabled the company to build the world's first commercial HVDC power link between the Swedish mainland and the island of Gotland.

Since this installation, ABB has continued to develop HVDC technology, replacing the fragile mercury-arc valves in the 1970s with semiconductor devices.

ABB maintains its lead in HVDC technology and to date, has installed 60,000 MW of HVDC transmission capacity in 70 projects, and is a market leader in the manufacture of high-voltage transmission cable as well. ABB's HVDC technology has had a truly revolutionary impact on the way that electric energy is delivered all over the world.

Some of the world's biggest cities, including Los Angeles, São Paulo, Shanghai and Delhi, rely on HVDC transmission to deliver huge amounts of electricity, often from thousands of kilometers away, with remarkable efficiency and minimal environmental impact.

ABB's achievements using this remarkable technology include the world's longest and most powerful HVDC installation, the Xiangjiaba- Shanghai power link currently under construction in China, which will deliver 6,400 MW of electricity over 2,000 km (shown here) and the world's longest underground cable transmission system, the 180 km Murraylink HVDC Light project in Australia.

The improvements achieved by ABB drives in energy efficiency, productivity and process control are truly remarkable. In 2008, ABB's installed base of low-voltage drives saved an estimated 170 TWh of electric power, enough to meet the annual needs of 42 million European households and reduce global CO2 emissions by some 140 million metric tons a year. That is like taking more than 35 million cars off the road for a year. As society faces the challenge of reducing environmental impact while meeting rising demand for electricity, ABB’s drives will be making a positive contribution to a better world.

Since ABB is also one of the world's major suppliers of all types transformer components – insulation materials and kits, tap changers, bushings, and electronic control equipment – the company is in a unique position to control product quality and performance.

Serving the new electric power markets

Since the inception of ABB in the late 1980s several major changes in the electric power markets have occurred. As the original domestic, country-based networks have been built out and matured, markets were opened up and deregulated in the western world to promote competition and efficient interconnections and creation of regional networks and markets. This evolution led to a change in relations between transformer manufacturers and buyers, from local to more global relations, and with a greater focus on economic aspects on both sides. As a result, manufacturers also had to become more global, leading to consolidation and concentration of the industry. ABB was perfectly prepared for this development, and emerged as the world leader in power transformers.

Simultaneously, the emerging markets in Asia and South America started to have a major influence, and later dominated the demand for power transformers. The rapid build-out in China and later India and other emerging markets created a boom period for transformers during the first decade of the new century, causing very high material prices for copper and core steel, and long delivery times and various other imbalances. A very rapid build-out of manufacturing capacity occurred particularly in Asia, causing a substantial overcapacity at the end of the period, with new imbalances and instabilities in material prices. ABB, with its global position and common technology, emerged as a major forerunner during this period.

In the present market, utilities and other power transformer buyers have a much more complex procurement process. Many of their local manufacturers and sub-suppliers are gone and many new unproven players have emerged. The local service support organizations have been transformed or are no longer available. Economic pressure has increased and new load patterns and highly loaded networks are challenging demands on the reliability and stability of the networks. Safe and reliable operation is a key but requires a procurement process for transformers and other equipment that can correctly identify quality products. This is a formidable challenge. ABB supports its customers in this new challenge by delivering a very well proven and reliable product with verified quality properties as well as a stable service and support organization.

Power system reliability

Modern power systems are increasingly complex with a large number of individual components. To ensure reliable operation, it is essential that the key elements, such as large power transformers, have a very high degree of availability, minimizing the outages of individual components or whole blocks of power generation.

The ability to withstand short-circuits is recognized as a very crucial function of power transformers in the network. The International Electrotechnical Commission (IEC), Institute of Electrical and Electronics Engineers (IEEE) and other commissions, specify the requirements on power transformers and how their performance should be verified. There is, however, extensive evidence that many transformers are not as shortcircuit proof as assumed. Failures caused by short-circuits are still a major cause of transformer outages, and failure rates vary widely between different countries and systems, depending on network characteristics and equipment installed.

Different networks have varying problems. In rapidly developing regions with increasing demand for electric power, more and more generating capacity and interconnections are added to existing systems. However, the western world is characterized by expanding cross-border electricity trade, integration of wind and other renewables, changing load flows and aging components. Several of these circumstances mean that old as well as new transformers will be exposed to even more demanding severe short-circuit stresses.

Assuring transformer quality

ABB has continued its predecessors' active participation in international bodies such as CIGRE (the International Council on Large Electric Systems), IEC and IEEE helping to establish stringent standards on test levels and test procedures to verify transformer performance and quality under various operational conditions. Successful factory acceptance testing of new transformers is necessary but not in itself sufficient to demonstrate service quality in all respects. Dielectric performance is very well covered by appropriate international standards that have been developed over the years.

The areas of thermal and mechanical integrity, however, are arenas where design and production weaknesses can pass tests without being detected. ABB has therefore made specific efforts in design, production, supply chain and testing philosophy of large power transformers to verify thermal and mechanical performance. A key measure of the mechanical integrity of the transformer is a short-circuit test, which ABB has promoted and successfully performed more frequently than any other supplier.

Mechanical rigidity of the transformer will become one of the most vital performance factors for the future.

There are three reasons for this:

- The ability to withstand short-circuit (SC) stresses

- Seismic requirements

- Transport handling

SC forces give rise to mechanical forces on windings that can reach hundreds of tons in milliseconds. The current peaks and the corresponding forces depend on many factors. In high-voltage systems, the most probable type of SC is a single-line-to-earth flashover, normally due to environmental conditions such as a lightning strike on the line, etc. The relative severity of the different types of faults depends on the characteristics of the system, in particular on the SC impedance value of the transformer and the SC apparent power of the system.

Forces and related withstand criteria in windings can be split into two components: radial forces and axial forces.

The failure modes for radial forces include:

- Buckling of inner windings

- Stretching of outer windings

- Spiraling of end turns in helical windings

The failure modes for axial forces include:

- Mechanical collapse of yoke insulation, press rings and press plates, and core clamps

- Conductor tilting

- Conductor axial bending between spacers

- Possible initial dielectric failures inside windings, followed by mechanical collapse

The SC forces are calculated in ABB with advanced computer programs based on detailed finite element methods (FEM) that also take into account axial displacements caused by workshop tolerances and pitch of helical type windings.

Windings are dimensioned for maximum compression forces, where dynamic effects are included. An extremely important feature of ABB's SC technology is that inner windings subject to radial compression are designed to be completely self-supporting with regard to collapse by "free buckling". This means that the mechanical stability of the winding is determined by the properties of the copper and conductor geometry only, a cautious design principle that has served ABB very well.

Short-circuit strength verification

The new IEC Standard 60076-5 (2006-2) provides two options for verifying the transformer's ability to withstand the dynamic effects of a SC:

- A full SC test performed at a certified laboratory

- A theoretical evaluation of the ability to withstand the dynamic effects of SC events based on the manufacturer's design rules and construction experience, in line with the new IEC guidelines.

Due to the high investment costs of SC test equipment, such test facilities are available in only a handful of locations in the world. The test requires power capacities in the range of a large power grid together with sophisticated control and measuring equipment. One such facility is KEMA in the Netherlands, where a number of SC tests were carried out on behalf of ABB. In spite of the high cost, ABB has performed a large number of such tests to guarantee quality. 35 ABB TrafoStar power transformers of different designs have been SC tested, with a failure rate as low as 11 percent ➔ 5.

5 TrafoStar's short-circuit reliability is more than twice the industry average

KEMA reports presented at CIGRE and other technical conferences show the total test failure rates for power transformers to be 28 percent of the performed SC tests for the whole industry [1]. ABB's test record over the last 16 years has been 5 failures out of approximately 50 tests, or only 10 percent. When the ABB test results are compared to the result of all other manufacturers the remaining manufacturers show SC test failure rates several times higher than ABB.

Future ambition for ABB quality efforts

In the future, new ways of rating transformers through better control of the thermal capability can help reduce the use of expensive materials. New standards should take the load profile into account, and allow for more flexible specifications to deal with more complex load patterns. This will require the integration of more intelligence. Other possibilities are to further increase the mechanical, thermal and dielectric integrity of transformers – to better equip them to deal with the greater stresses that will affect future networks. Since transformers stand for a substantial part of the network losses, energy efficiency programs will further require transformer designs and technology with lower losses.

Pieralvise Fedrigo

ABB Power Products, Transformers

Sesto S. Giovanni (Milan), Italy

[email protected]

Arne Hjortsberg

ABB Corporate Research

Baden-Dätwill, Switzerland

[email protected]

Thomas Fogelberg

ABB Power Products, Transformers

Ludvika, Sweden

[email protected]

-------------------------

References

[1] Smeets, R.P.P., te Paske, L.H. (2010) Fourteen Years of Test Experience with Short Circuit Withstand Capability of Large Power Transformers. Travek VIIth International Science and Technical Conference on Large Power Transformers and Diagnostic Systems, Moscow, Russia.