Partial discharge (PD) is the name given to the partial breakdown of the electrical insulation in high voltage (HV) switchgear and cables. This is a destructive process and, if unchecked, it will eventually lead to a complete breakdown of the insulation and failure of the asset. If the distribution network operator (DNO) is unaware of the PD, the failure will often occur without warning and this can cause a range of unwanted problems including unplanned outages, unscheduled repair work and potential safety implications—all situations that create considerable expense to the DNO.

EA Technology has for many years been developing and producing on-line PD monitoring systems for plant and equipment deployed on HV electricity distribution networks as part of its ASTUTE condition monitoring service. This provides a check on the health of the HV equipment 24/7 whilst the equipment remains in normal operation. More recently, this technology has been extended to monitor HV cable,s which is the main focus of this article.

Historically, in order to assess the condition of a HV cable, it was necessary to temporarily remove the cable from service and perform off-line PD testing, such as very low frequency (VLF) testing, but this is now changing. EA Technology has developed a novel technique known as the ASTUTE Cable Monitor for performing on-line 24/7 PD monitoring of underground HV cables. In recent years, this has been incorporated into the ASTUTE condition monitoring service. Continuous PD monitoring provides a good indicator of the health of an individual cable, as well as allowing a defective cable to be repaired or replaced in a timely fashion before it fails catastrophically. This addition to the traditional substation HV equipment monitoring capability has proven to be highly beneficial to network operators.

In theory there is no upper voltage limit for the ASTUTE cable condition monitoring service. To date it has been applied from 11kV cables up to a 220 kV transmission cable in a tunnel in China. The monitoring service is applicable worldwide and is being used by utilities and many other business sectors in Europe, North and South America, Asia and Australasia, as it continues to evolve.

ASTUTE Cable Monitor

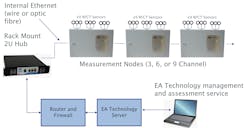

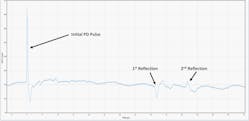

The ASTUTE Cable Monitor can detect minute high-frequency electrical pulses that are induced on to the cable screen/sheath at the position of partial breakdown of the insulation, known as the discharge site. These pulses travel along the cable to the end terminations where they can be detected using a high frequency current transformer (HFCT) simply clipped around the cable earth or grounding strap. Waveforms from the HFCT sensors are captured by measurement Nodes and the data is then fed back to a Central Hub where it is processed and analyzed.

Therefore, this addition to the traditional substation HV equipment monitoring capability has proved highly beneficial to network operators as illustrated in the following three case studies.

Case Study 1 – INEOS

INEOS is a multinational group specializing in petrochemical production and Grangemouth in Scotland is one of its largest sites as it includes a crude oil refinery as well as INEOS’ Olefins and Polymers UK business. INEOS operates its own Combined Heat and Power (CHP) plant as well as one of the largest private electricity distribution networks in Europe. The CHP plant also exports electricity to the UK’s National Grid.

To connect the CHP plant to the primary substation on site there are 18 feeder cables. These are arranged as two ganged 33kV circuits, with each phase having three single-core separate cables in parallel to carry the full output current of some 2,300 Amps from the CHP plant. Each cable has cross linked polyethylene (XLPE) insulation and are approximately 1 km (0.62 miles) in length.

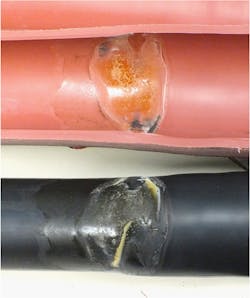

The defective joint was sent for forensic examination to EA Technology. Evidence of PD was discovered, and the root cause diagnosed as moisture ingress. (INEOS and EA Technology were joint winners of the 2018 Institute for Asset Management Award for Innovation as a result of this example of condition‑led active asset management work).

Case Study 2 – NIE Networks

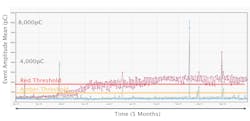

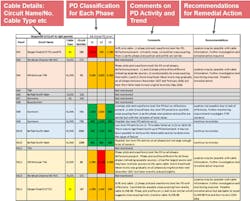

Northern Ireland Electricity (NIE) Networks owns and operates the electricity distribution network, which transports electrical energy to over 900,000 customers in Northern Ireland. Part of this distribution network comprises over 3,700 km (2,300 miles) of HV underground cable, which ranges in age from present day to 75 years old. Naturally, some of these cables are now experiencing age related failures and require replacement. However, variation in the condition of the network cables means that many can still continue to provide further service despite their age. The problem facing NIE Networks was how to determine the relative condition of the individual cables so that it could select and prioritize those that need to be replaced, and how to perform the requisite strategic and commercial planning to justify their replacement. Three separate ASTUTE™ Cable Monitor systems were installed at three separate NIE Networks 33/11 kV primary substations in Northern Ireland in October 2017 and have been monitoring a total of 72 - 11 kV cables since then. The circuits being monitored were selected in relation to their criticality with respect to the consequence of failure - which includes both network risk and physical location.

In addition to providing a useful benchmark against which to judge future changes in the cable condition, this provided a readily visible means for prioritizing remedial work. This information was used by NIE Networks, for both day-to-day network management as well as the justification, planning and prioritization of future network investment and cable replacement programs. Avoiding outages and only replacing sections of cables that are in poor condition, allowed NIE Networks to save money as well as enhancing network performance.

Case Study 3 - Biomass Power Plant

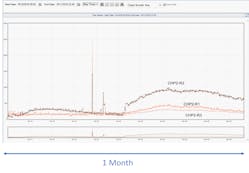

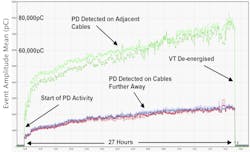

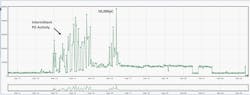

An ASTUTE Cable Monitor was installed at one of Northern Powergrid’s 33/11 kV primary substations to monitor a pair of critical 11kV XLPE insulated cables, (Circuit A and Circuit B), each over 4 km (2.5 miles) long that connected a biomass power plant to the 11 kV distribution network. This action was taken following the discovery of raised PD levels on Circuit B blue-phase during routine spot measurements taken using EA Technology’s hand-held UltraTEV Plus2 PD detection instrument.

However, the Cable Monitor also picked up some intermittent PD activity on the blue-phase of Circuit A. When active, the magnitude of this PD was even greater, reaching levels between 20,000 – 50,000pC at times. Due to its intermittent nature, this source had not been detected at the time the spot measurements were performed. This illustrates the benefits of a continuous on-line monitoring system. The position of this source was estimated to be between 95% and 97% along the cable length from the substation.

The locations of the two PD sources were compared to Northern Powergrid’s cable records and found to correspond closely to known joint positions. The joints were subsequently excavated and replaced during a holiday period whilst the biomass plant was off-line. Following the cables’ return to service there was no further evidence of PD on the cables. The ASTUTE™ system had averted the sudden failure of the cables, and corresponding loss of energy production, and allowed the repair work to be conducted in a controlled manner at a suitably convenient time.

The ASTUTE condition monitoring service is likely to be particularly attractive to network operators that do not have their own in-house PD specialists, and instead would prefer to focus their efforts on their core business operating and maintaining their network, but doing so using the best condition information available to them.

Ramiz Ahmed B.Eng, MSc, MIET is currently the Head of Monitoring Services Team at EA Technology. His team focuses on providing fault location and management services to Private and Distribution Network Operators. Ramiz is constantly working on developing new insights and monitoring solutions using EA Technology’s vast range of instruments, allowing his customers to move from reactive to preventative asset management solutions.

Graham Earp is a Principle Consultant Engineer with EA Technology and is based in the United Kingdom. He has enjoyed numerous development roles since joining EA Technology in 1991, including responsibility for evaluating and implementing innovative technologies for the detection of Partial Discharge (PD) in High Voltage plant and equipment. He holds a degree in Electronic Engineering from the University of Liverpool and is a Chartered Engineer with the Institution of Engineering and Technology.