In recent years, power grids and utility networks across the globe have undergone unparalleled amounts of stress and are today experiencing issues never seen before to this degree. Extreme temperatures, unprecedented natural disasters, increased global energy consumption and aging utility networks are just a few of the many elements causing major issues within power grid networks worldwide. These issues have brought the topic of power grid resiliency to the forefront of industry discussions and made it the focus of many power and utility organizations.

Specifically, the issue of aging wooden utility poles and their increasing vulnerability has become a major obstacle to grid resiliency. With this and other sources posing new and unforeseen threats to the grid every day, improvements must be made to improve the resiliency and overall life span of power grid networks, including what types of power poles are used to deliver electricity. Numerous organizations, standards, safety considerations and environmental conditions play important roles in the current landscape of power grid resiliency.

In practice, power grid resiliency involves protecting the network from potential issues and disruptions through careful planning, preparation and allocation of available resources. At any point in the network, from generation to transmission to distribution, the network can be attacked, be compromised or malfunction in some way. Some of these issues are not uncommon and can be prevented during routine maintenance or fixed at the source by a field electrician. Other issues are more complicated and serious, causing major outages and wiping out entire networks. To prepare for this, the industry needs to implement and invest in resiliency improvements, designing networks with a certain amount of redundancy that enables the grid to be more easily restored when an event occurs.

Resiliency Guidance

Exploring resiliency among other things, utility and energy organizations have worked for many years to develop standards and operational guides that prescribe best practices for the safest, most effective management of every part of the power and utility system.

One of the most well-known and adhered-to codes is the National Electrical Safety Code (NESC), published exclusively by the IEEE Standards Association (SA). First developed in 1913, the NESC sets the ground rules and guidelines for practical safeguarding of utility workers and the public during the installation, operation and maintenance of electric supply, communication lines and associated equipment. The guide, a working document updated every five years to account for changes in the industry and technology, has begun to dive more deeply into threats to the network and overall power grid resiliency in recent years.

Today, power grid resiliency and safety, as prescribed by the NESC, are inextricably linked as the utility landscape continues to change rapidly and face novel issues. The overall level of safety within the utility industry increases and will continue to do so as resiliency improvements are made, but such improvements cannot be made without adhering to the most recent, innovative standards in the field.

Aging Overhead Network

A critical area in which the NESC addresses and works to progress power grid resiliency is overhead utility pole networks and worker safety. When it comes to utility poles, a slowly developing but growing obstacle the industry faces is the aging of the entire overhead utility network. When the first version of the NESC was released in 1913, the standards were aligned with that era, characterized by a changing network structure that was the result of rapid electrification and the running of utility lines through previously installed wooden telegraph poles.

However, a key driver of the utility pole network known today came with the Rural Electrification Act of 1936. The act laid the groundwork for widespread expansion of the network, with most infrastructure completed by the 1970s.

As of today, most of the U.S.’s utility poles have been in use for 50 years to 60 years, which raises concerns about resiliency when considering the biological life expectancy of wood. The life span of a wooden pole is expected to be around 60 years to 70 years in terms of its structural integrity and strength. Thus, with most utility poles being installed by the 1970s, almost 54 years ago now, and the average life expectancy of a wooden pole being around 60 years to 70 years, this means most utility poles in the network are in the last third of their life cycle.

As these poles get closer to the end of their life span, their structural integrity and ability to withstand harsh conditions and major disruptions continues to diminish. Pair this with the uptick in recent years of extreme weather events, and it becomes a dangerous combination that has created widespread power issues and unsafe work environments for electrical workers.

Searching For Solutions

With power problems predicted to continue and become more frequent as utility poles age, efforts to improve the resiliency of utility pole networks and the overall power grid have increased. Industry experts, like those from IEEE SA who contribute to the NESC, are continuing to look for novel methods, technologies and innovations that can improve the strength and resiliency of aging utility poles. For example, some researchers are looking into creating a digital twin of the base infrastructure of a utility system, so it can be integrated into other parts of the system like the pole networks.

Other organizations are conducting analyses to determine the ages of poles in different parts of the network to identify where the stronger and weaker sections are. This information can be sent to utilities, so they can properly distribute resources to conduct maintenance on and install reinforcements to the oldest and most vulnerable poles in their network.

Other areas of research are looking to improve pole resiliency by finding material alternatives to wood that are more durable but also can withstand the conditions of electrical transmission. Materials like fiberglass, concrete and more have been tested to determine whether they are viable alternatives to wood, but each has been found to come with their own set of issues that can create problems and lead to failure.

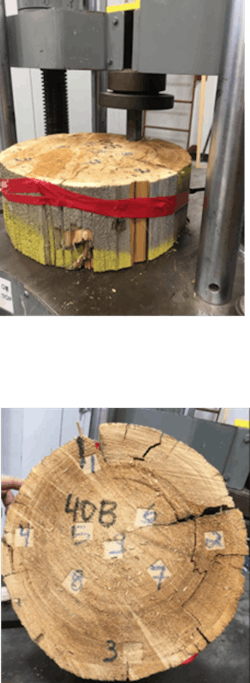

To further the search for standardized solutions to pole aging, a recent study was conducted by Mississippi State University on a sample of utility poles that had been in service for varying amounts of time to see how excessive conditions and loads would affect breaking and failure. Of the poles, 16% broke between 6 inches (152 mm) below and 12 inches (305 mm) above ground line (AGL), 63% broke between 1 ft to 4 ft (0.3 m to 1.2 m) AGL. The remaining 21% broke above 4 ft AGL. This result was expected, as a pole that is 60 years to 70 years old cannot be expected to be capable of carrying the same load as a pole that has only been in the ground for 5 years to 10 years. Other studies of a related nature have yielded similar results, demonstrating the potential catastrophic effects of pole aging.

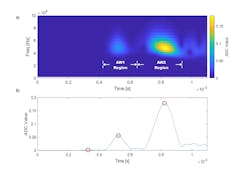

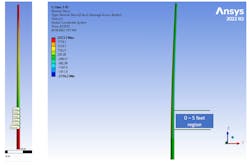

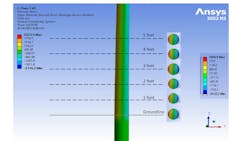

Based on the Mechanical Properties of Wood, a report published by the U.S. Department of Agriculture Forest Service on Douglas fir, a simulation was built according to the ASTM for standard test methods of static tests of wood poles (ASTM D1036-99, 2017). The result of the simulation suggested a similar cross-sectional stress level occurs from ground level up to 5 ft (1.5 m) AGL. This conclusion agrees with the break test result, which showed 63% of the poles break between ground level and 4 ft (1.2 m) AGL.

Operational Resiliency

The NESC actively works to address findings from research and testing by standardizing methods for reinforcing the overhead utility pole and line network to make it more resilient to complications. Section 8 of the code looks at overhead utility lines and ratings that measure operational resiliency. It includes standards that detail network hardening plans and systems that include class upgrades for aging poles that protect legacy electric lines in high wind areas.

Section 8 also targets resiliency through standards that delineate targeted trussing of weak poles. This involves not replacing the poles themselves but rather installing trussing along key poles that can prevent catastrophic fails and domino effects. This way, networks can potentially lose two poles or three poles instead of 50-plus poles, enabling utilities to minimize the damage and recover from an adverse event more quickly.

All the standards detailed in section 8 use different methods to build strength within the network and make the grid and utility pole network more resilient by reinforcing weak parts of the network. Such methods are crucial to the overall advancement of network resiliency across the globe.

Future Focus Areas

Finding novel solutions to improve resiliency of utility poles networks will continue to be of high importance in the coming years. When looking toward the future, making predictions on possible solutions for improving wooden pole resiliency will be heavily based on future weather, environment and technological advancements. With the chances of massive changes in weather events being high, power grid — and specifically pole — resiliency is going to be extremely important and something the NESC helps to address and will continue focusing on in future iterations.

Based on current patterns, future versions of the NESC are likely to contain specific changes and more detailed standards related to resiliency. One prediction is designated loading zones and guidelines for determining these zones will change. This can safeguard networks by distributing loads more evenly across the network and away from weak points more susceptible to issues. Teams will have to identify how the zone changes affect loads for the overall network to ensure they are reinforcing, and not hurting, overall resiliency.

In relation to aging utility pole networks and grid resiliency, the NESC also works to address worker safety standards that detail best practices for safely approaching and performing all electrical work. Section 4 of the worker safety portion of the NESC, which was updated in 2023 to reflect the most recent landscape, addresses workers being well equipped and prepared for the job and task at hand. With extreme weather events sweeping across the world and bringing network repairs and resiliency concerns to the forefront, it is important electrical workers have the right tools and equipment as well as follow the proper procedures to deal with such specific issues and tasks. By identifying upcoming weather patterns and threat-heavy seasons, utilities can modify their preplanning and deployment processes to prepare for these events, allowing them to better protect and ensure the safety of their employees.

Overall, the growing variety of unforeseen conditions that are becoming increasingly threatening to the health and stability of global utility networks and power grids worldwide calls for widespread action. IEEE SA’s work within the industry through the NESC and other publications will continue to target power grid resiliency and establish standards that prescribe the safest ways for improving the network now and in the future.

Wayne Hall ([email protected]) is a member of IEEE SA and the current President of Utility Asset Management Inc., in Denver, Colorado. Currently, Wayne is named on four US patents related to using ultrasound on wooden structures. He is also a qualified supervisor in wood preservation and wood products treatment (Colorado), is an FAA qualified drone operator, and was one of the reviewers for the Colorado Department of Agriculture’s recently released Colorado Wood Products Commercial Pesticide Application and Safety Training Study Guide. Wayne has an undergraduate degree and a post graduate diploma in business from the University of Auckland and is a certified PMP (Project Management Professional) through the Project Management Institute.