New Technology for Ameren Transmission: Advanced Voltage Control for Grid

Ameren Transmission has energized the first two of four innovative upgrades to ensure its grid remains stable as the utility transitions to clean energy sources. Known as Static Synchronous Compensator (STATCOM), the technology helps ensure customers will have safe, reliable, and affordable energy as fossil fuel energy centers retire within the Ameren service territory.

Fossil fuel energy centers, in addition to generating megawatts, also provide reactive power capabilities via generator excitation systems, thus controlling the Transmission System Voltage during steady state and transient conditions. As these plants retire, in addition to losing the megawatt production, we also lose the voltage control these plants provide, which could lead to system stability issues and violation of NERC standards. Because of Ameren's commitment to clean energy and achieving net-zero carbon emissions by 2050, Ameren Transmission began planning for the retirement of several energy centers within the Ameren service territory.

Transient conditions known as Fault Induced Delayed Voltage Recovery (FIDVR) events can result in grid instability and loss of customer load. By performing system simulation of FIDVR events along with other transmission system planning studies, the team of planning engineers working with design engineering identified four locations within the Ameren grid that would require transient voltage control devices in order for it to operate in a steady and reliable manner after the expected retirement of certain coal-fired energy centers.

A team consisting of planning, design, project management, construction, and maintenance engineering was formed to develop a specification for the needed voltage control devices factoring in steady-state and transient performance, initial cost, operations and maintenance cost, safety, and long-term sustainability of the technology. Several types of solutions were considered including Synchronous Condensers, traditional Static Var Compensator (SVC) systems, and STATCOMs.

After reviewing multiple solutions and vendor proposals, the team decided the STATCOM solution best met the requirements of the specification, providing significant performance benefits over SVC and Synchronous Condensers in terms of increased reactive power capability under transient low- and high-voltage conditions, speed of response, and reliability. The STATCOM design, based on voltage source converter and Insulated-Gate Bipolar Transistor (IGBT) power electronics, provided the most current technology based on industry standard power electronic components, thus offering long-term sustainability, simpler design in terms of system integration (reduced harmonics), and the lowest operations and maintenance costs.

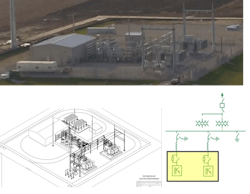

A STATCOM installation has a relatively small footprint, requiring an area 250 ft x 250 ft for a 250 Mvar installation. The STATCOM installation is shown in Fig. 1 along with design layout and one-line.

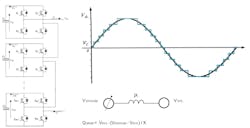

The power modules and control (highlighted yellow in Fig. 1 one-line) are located within the building and provide the basic building block of the STATCOM. The power module stacks schematically pictured in Fig. 2 are composed of dc capacitors and four IGBT switches per module. The power modules maintain charge on the dc capacitors, which are then gated on and off to increase or decrease the voltage to inject current through a series reactor. The net effect is positive or negative reactive power injected into the transmission system to regulate system voltage.

The first two of four STATCOM installations are near Wood River and Peoria, Illinois. These two locations provide advanced voltage control for Ameren customers affected by the retirements of major power plants in each area. These specific applications of STATCOMs and future applications of the technology are also critical in transitioning the State of Illinois to a carbon-neutral economy and meeting its goal of 100% clean energy by 2050.

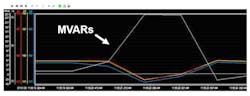

The Wood River area STATCOM provides transient voltage recovery to a highly industrialized corridor, which has a large energy demand and requires a stable voltage on the system to assure manufacturing facilities remain online during these contingency events. After the Wood River area STATCOM was installed in 2019, it has proven to meet high-performance standards. Sample performance of the Wood River area STATCOM is shown in Fig. 3 for a nearby 138-kV line to ground fault.

The above graph of the event showed the STATCOM injecting reactive power, limiting the voltage sag to less than 4% and restoring voltage to its pre-event state within 2 secs. Ameren compared the voltage dip before and after STATCOM was installed using system simulations. Without the STATCOM, the 138-kV voltage in the area would have dipped to approximately 90% of nominal voltage over an extended period of time. With the STATCOM, the 138-kV voltage was slightly higher than 96% of nominal voltage during the system disturbance, which would have exceeded the system performance prior to the generation retirements in the area.

The second two of four STATCOM installations are in Dupo, Illinois, and the southern portion of St. Louis County, Missouri. These STATCOMs are providing transmission support and voltage control to areas impacted by the retirement of Ameren's Meramec Energy Center located in St. Louis County along the Mississippi River. The St. Louis County STATCOM is also part of Missouri's Smart Energy Plan, a multiyear plan that includes more than 2000 projects to upgrade the energy infrastructure to support a cleaner and stronger energy grid.

STATCOM technology will be integral to support Ameren's goal of reaching net-zero carbon emissions by 2050. In addition to retiring its fossil fuel energy centers, Ameren is planning for its largest-ever expansion of clean wind and solar generation, all while maintaining the reliability and affordability that customers have come to expect.

About the Author

Suzanne Pohlman

Suzanne Pohlman is an Ameren Transmission project manager, leading a team that manages transmission line and substation projects of varying scope and complexity with capital budgets ranging from several millions to more than US$200 million. Responsible for some of the most complex and challenging projects in transmission, she holds a BSCM degree from Southern Illinois University Edwardsville and is an active member of the SIUE construction department's advisory board.

Robert J. Rauschenbach

Robert J. Rauschenbach is Ameren Transmission director of electrical design and has more than 35 years of experience in the design and planning of Ameren's T&D system. He holds a BSEE and MSEE from the University of Missouri Rolla and is also an adjunct professor in the University of Missouri St. Louis and Washington University Joint Engineering Program.