Wildfires have become increasingly common, larger, more expensive to fight and deadlier. They are costing billions of dollars in natural resource and property losses. Of significance, wildfires also pose an extreme risk to utility infrastructure. Every year, utilities spend millions of dollars replacing wildfire-damaged wood utility poles and infrastructure. Replacing fire-damaged equipment is extremely expensive, disrupts routine maintenance schedules and, most importantly, reduces the reliability of electric service.

Utilities have tried a variety of ways to prevent damage to utility infrastructure from wildland fires. Approaches range from doing nothing to installing metal poles and all points in between. Utilities face some tough questions when it comes to wildfire mitigation: Is spending more funds for poles made of fire-resistant materials a good approach? Is pretreating wood poles and utility infrastructure with long-term fire retardant (LTR) an equally viable and potentially less costly option?

LTRs have proven to be an effective tool in reducing the damage and destruction of wood utility poles from wildfires. Pretreating utility poles with LTR ahead of a spreading wildfire can increase the odds of their survival.

Fire Retardants

The same fire chemicals traditionally used by wildland fire agencies can be used by utilities as a treatment method on utility infrastructure. They include Class A foams, gels or water enhancers, and LTRs.

Class A foams are dependent on the water they contain. Foams typically evaporate within one to four hours of application. The surfactants in Class A foam significantly reduce the water’s surface tension and, when mixed with air, create a superior foam blanket that surrounds fuels with a thick layer of tiny bubbles containing water. This creates a barrier between the fuel and fire, knocking down the fire faster than water alone, and enabling firefighters to see the areas of application. Making the water significantly more effective reduces the amount needed to extinguish the fire. This reduces water damage and increases firefighter safety through quicker knockdown, requiring less time to locate and extinguish residual hot spots.

Class A foams have some limitations. Performance is decreased in high heat situations and during periods of long exposure to sun and wind, which speeds evaporation of water from the foam solution and renders it less effective. Class A foams must be applied immediately prior to flame impingement (within one hour or less), thus requiring application crews to work near the fire area.

Like Class A foams, water enhancers or gels depend on the presence of water to be effective. Gels break the fire triangle by suffocating oxygen from the fuel and cooling the heat source, thus providing a thermal barrier. Gels cling to vertical surfaces, which prevents rekindles—thereby reducing property damage. Because of their increased effectiveness over water alone, gels provide an additional margin of firefighter safety. While gels tend to retain moisture and resist evaporation better than foams, they also lose their effectiveness after periods of exposure to ambient temperature, relative humidity, sun and wind.

Some manufacturers suggest, once dried, gels can be rehydrated by the application of additional water. This is a myth. Any dried gel remaining on unburned fuel will be rinsed off by a subsequent application of water. Because of these characteristics, gels are best when used within hours of flame impingement. Because of their limited duration of effectiveness, gels also require application crews to work near the fire area.

Foams and gels both rely on the water they contain to be effective; they do not chemically alter the combustion process. Once dry, they are no longer effective. In contrast, LTRs do not depend on the presence of water to be effective. LTRs consist primarily of ammonium phosphates and other functional components. Phosphate-based LTRs chemically modify the combustion process in cellulosic fuels, reducing the rate of spread. This occurs with or without the presence of water. Fuels treated with LTRs result in less combustion. This reduces fire intensity and rate of spread as well as increases safety for those working on the fire line.

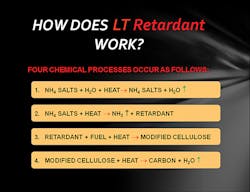

From a reaction standpoint, LTRs chemically alter the combustion and decomposition process of fuels as well as reduce flammable gasses and vapors. After the fuel is coated with LTR and exposed to fire, a chemical chain reaction takes place. During this chain reaction the combustion process is modified minimizing the emission of common volatile gases and producing water vapor which cools the fire. The end result is a “graphite-like” carbon char that continues to insulate the fuel surface and impede further combustion. From a safety perspective, this characteristic is highly desirable, as it does not require application crews to work near the fire area. LTRs can be applied several days prior to fire passage, and they will remain effective for days and even weeks after application.

Long-Term Retardants

Testing and evaluating the use of fire retardants, by simulating conditions that would typically be encountered during a wildfire, can be conducted on wood utility poles to compare the effectiveness of various fire chemical agents. A series of tests were conducted by Pacific Gas and Electric Co. (PG&E) in which utility poles were treated and exposed to a standardized flame for a specified period. Based on the experience of staff at PG&E and testing conducted by the authors, LTR products were determined to provide the best results in this evaluation.

Ground application of LTRs to wood utility poles can prevent ignition and eliminate replacement costs. Application in rights-of-way, perimeter fuels around substations, switchyards, valve lots and mountaintop communications sites can prevent a fire from entering the area, thus protecting utility equipment and infrastructure. Also, ground application is not subject to limitations of weather, inversions, smoke conditions and night operations that may hinder dissemination using air tankers and helicopters. LTRs can be applied with back pumps, utility terrain vehicles with pumps and poly tanks, garden sprayers (highly effective for poles with limited accessibility), water tenders, hydro mixers and fire engines.

In some situations after application, ignition of wood poles or fuel is still possible. This may be a result of improperly mixed solution, improper application of the product, damage or checking of the pole, or heavy fuel loading near poles. The performance of any product depends on proper mixing and mix ratio to achieve the proper viscosity and salt (active ingredient) content. LTR properties remain effective for weeks to months after application. Because of this characteristic, retardant can be applied well in advance of fire impact, making it unnecessary to expose personnel to potentially more dangerous work situations near an approaching fire. LTRs remain effective even months after the water has evaporated, unless they are removed by rain.

Readily available scientific data regarding the environmental and safety effects of fire retardants is an important consideration for utilities. For example, all the commercially available Phos-Chek LTRs from Perimeter Solutions have been evaluated and tested extensively by the U.S. Forest Service (USFS) and shown to have no adverse health effects or negative environmental impacts when properly applied. In fact, they are included on the USFS’s qualified products listing and approved by the Canadian Interagency Forest Fire Centre. Of note, Phos-Chek products are the only LTRs currently approved by the California Department of Forestry and Fire Protection.

Examples of Successes

During the 2015 California wildfires, significant damage and destruction occurred in the areas of Amador, Butte, Calaveras, Fresno, Lake and Trinity counties. Pretreating poles with LTR by one utility prevented the loss of at least 312 T&D poles. This resulted in a savings of more than US$6 million in infrastructure alone for the utility. The 2015 Asset Protection on Wildland Fires publication included the following quote from Robert Cupp, PG&E’s incident commander for the Rough fire in Fresno County: “Without a doubt, pretreatment of PG&E infrastructure with long-term fire retardant on the Rough fire saved thousands of dollars in expensive repair and replacement expenditures. More importantly, our efforts to protect these assets allowed PG&E to restore service more quickly and maintain service reliability for our customers.”

Major incidents in 2017 included the Helena fire in Trinity County as well as the fire siege in Sonoma and Napa Counties, which included the Tubbs, Nuns and Atlas fires. One utility pretreated 200-plus transmission poles, 1000-plus distribution poles, a mountaintop communications site, an electric substation and a gas transmission substation with LTR prior to these events. The utility’s actions reduced damage and destruction, resulting in significant savings to its infrastructure.

Utilities are increasingly focusing on developing effective wildfire mitigation, vegetation management and pretreatment programs to minimize losses. LTRs have been proven to be the most effective treatment for a variety of fuel types. An efficient and effective pretreatment program generates four extremely important benefits for utilities:

- Enhancing safety for the public and responders by keeping the electric utility up and energized

- Increasing utility cost savings through avoidance as well as mitigation of damage and destruction to infrastructure

- Improving service reliability by reducing potential outages to critical community facilities

- Minimizing disruption of normal business activities as maintenance resources are not redirected to perform fire damage repair work.

Utility pole replacement costs can be $20,000 or more per pole. By comparison, the cost of pretreatment amounts to less than $20 per pole. When infrastructure is protected, valuable maintenance crews can focus on their normal duties rather than spending days replacing damaged or destroyed poles and equipment. Pretreatment program benefits and cost savings can be instrumental to utilities focused on achieving their goals of safety, reliability of the electric utility grid, affordability and customer satisfaction.

Scott Holmquist ([email protected]) has more than 32 years in fire service, retiring as the assistant deputy director of fire protection operation at the California Dept. of Forestry and Fire Prot. At CAL FIRE, oversaw department operations for the aviation, fire chemicals, and mobile equipment programs. Since 2008, he has been the owner and principal consultant of Pursue It Consulting. Previously, he spent more than four years as a public safety specialist for PG&E.

Ron Raley ([email protected]) has 49 years working in Wildland Fire Management. He spent 35 years with the United States Forest Service (USFS) finishing his career with them as the Deputy Director of Fire and Aviation Management for the Pacific Southwest Region (R5). While at the USFS he held numerous positions on Incident Management Teams and served as a Type I Incident Commander dealing with complex incidents across the country. For the past 13 years he has served as the owner and principal in Raley’s Forestry and Wildfire Management. He is a Registered Professional Forester and a long standing member of the Society of American Foresters.