Habersham Electric Membership Corp. set out in June 2018 on an ambitious multiyear journey to assess and improve distribution reliability for its 26,000 members. The utility’s goals for a reliability program were simple: reduce outages, make the grid more resilient to storms and bounce back quicker from major weather events.

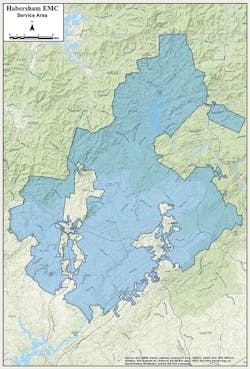

A rural electric cooperative with 3700 miles (5955 km) of overhead line, Habersham Electric Membership Corp. (HEMC) is located approximately 80 miles (129 km) north of Atlanta, Georgia, U.S. The utility began its reliability journey with an aggressive vegetation management program, called the Easement Clearance Initiative. The aim was to minimize and eliminate tree touches as well as clear overhead line easement areas.

Next, HEMC determined the best untapped opportunity for reliability improvement was to address overhead equipment issues. According to the U.S. Department of Energy, one-third of all non-weather-related outages is caused by overhead equipment. Typically, the approach for reducing the impact of equipment outages is aimed at minimizing downtime after an event has occurred. However, with the effectiveness of various problematic-equipment detection technologies, such as that from Exacter Inc., HEMC decided to be proactive and identify potential problems on the system so it could remove them before an outage occurs.

Invisible Problems

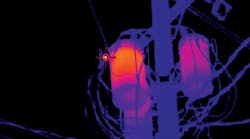

Almost all equipment problems are invisible to the human eye and silent to the ear. The most prevalent sign of failing equipment is partial discharge in the form of radio frequency (RF) emissions. The resulting conditions can include current leakage, dry-band arcing and tracking. While some arcing can be seen at night from the right viewing angle, much partial discharge takes place on the inside of the component.

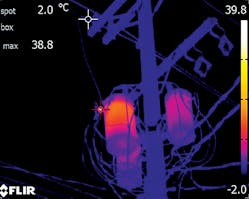

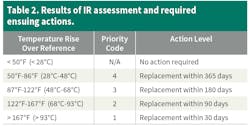

The second indicator of future equipment failure is the presence of heat. Equipment exhibiting temperatures 50°F (28°C) higher than ambient temperatures is a significant indicator of potential problems and important to identify. While visual inspection is not effective at finding most pre-fail conditions, it can help to locate important structural issues. This makes visual inspection an important part of any reliability improvement effort.

HEMC’s first step in assessing and improving distribution reliability was to establish a benchmark for the condition of its grid. The co-op’s overall motivation was to reduce its 2017 system average interruption duration index (SAIDI) of 195 minutes and system average interruption frequency index (SAIFI) of 2.08. A complete overhead health assessment of the system was necessary to identify areas and points of concern for predictive maintenance. Davey Resource Group Inc., a wholly owned subsidiary of the Davey Tree Expert Company, was contracted to perform system assessments using Exacter technology and infrared (IR) cameras to find invisible pre-fail conditions. DRG also performed visual inspections to identify any structural issues.

The priority for year one was to address the backbone of the system: the condition of all 512 miles (824 km) of three-phase lines. This would provide a benchmark for system wellness and identify specific points on the grid that should be the focus of preventive maintenance actions. Subsequent years would target historically problematic single-phase circuits.

2018 Findings

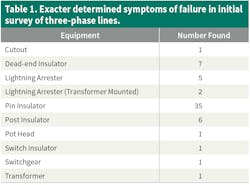

The Exacter portion of the assessment took six weeks to complete. Exacter technology identified and located all RF partial discharge being emitted on the system. In total, 60 components were found in a pre-fail state, exhibiting current leakage, arcing or tracking — the primary indicators of a future outage. This worked out to be one issue for every 8.5 miles (13.7 km) of line.

The Exacter process uses sensors mounted on vehicles. Each circuit is driven three times to four times (at posted speed limits) and automatically assessed to find locations where consistent partial discharge from lines occurs. To confirm and precisely locate the actual problem, field engineers use ultrasonic devices to identify the specific component emitting partial discharges. Photographs and video documentation are provided to ensure each find is legitimate, and not a false-positive reading. Results are presented in multiple formats, including geographic information system (GIS) compatible KMZ files, Google Earth, maps, Excel CSV spreadsheets, PDFs and an online portal that provides access to multiple years of data. Photographs of failing equipment and video confirmation of each find also are part of the deliverable.

The IR camera assessment was completed in approximately four months. These assessments take longer than the Exacter technology because field teams must stop at every pole to take readings. At each location, the DRG team established a reference temperature for the components. It uncovered 32 components emitting temperatures of 50°F (28°C) over the reference temperature. Of these, 10 were 100°F (55°C) higher. The IR assessment revealed one significant issue for every 16 miles (26 km). It is recommended these problematic equipment findings be replaced within one month to six months, depending on the temperature.

The combined Exacter and IR totals uncovered 92 components in pre-fail condition, an average of one targeted predictive repair for every 5.5 miles (8.9 km) of line. This assessment data will serve as a baseline as the reliability initiative moves forward.

Actionable Intelligence

By removing at-risk components, the system inherently becomes more reliable. It is like tending a garden every week vs. every six weeks. The garden being tended every week will have fewer weeds and be healthier. After year one and each year after that, the expectation is fewer and fewer components will be found in pre-fail condition. This translates into continuous improvement.

There also is an ensuing grid resiliency benefit from this approach, too. When a major weather event blows through, the deteriorating or failing equipment is most susceptible to causing an outage. By removing these susceptible components before the storm, there should be fewer outages and, certainly, fewer repairs to make. For HEMC members, this translates into faster recovery and bouncing back from the storm.

There are several things to note about the Exacter and IR assessment data. First, it gave HEMC a benchmark of how many components were in pre-fail condition before proactive maintenance was performed. This will enable the utility to evaluate progress in subsequent years. The most important benefit of the assessment is it gave HEMC specific points on the system that indicated the risk for a potential outage. HEMC members will receive no benefit unless those points of risk are removed. The data received must be viewed as actionable. Furthermore, maintenance must be performed to derive the benefit of fewer outages and continuous improvement. Otherwise, it is just information that was never acted on.

According to reporting data available to rural coops, the cost to make a repair after an outage vs. making a scheduled repair during normal business hours can be four times to five times more expensive. A crew can replace multiple components in a few hours if the replacement is scheduled. Compare that to the time it takes to locate the source of an outage, get the new piece of equipment and install it — especially at night or in after-storm-recovery conditions.

In addition, performing the work during regular business hours is much safer, a top priority of HEMC. Being able to avoid the uncertainties of nighttime repairs is a significant benefit on which one cannot put a price tag.

Shifting the Culture

HEMC’s service area in northeast Georgia is challenging. More than one-third of the land area is federal and state property. The land ranges from mountain rain forests — averaging 70 inches (1.8 m) of rain each year, the highest amount east of the Cascades — to 4000-ft (1219-m) elevations and suburban areas touching north of Atlanta. As a result, the utility has attracted skilled and responsive linemen who are used to going off-road, up mountains and through creeks, much like the original rural electrification workers did back in 1939. HEMC has been successful at leveraging this talented workforce and arming them with new technology tools, like Exacter, and a deliberate strategy to get ahead of outages, rather than respond to them.

Knowing exactly where points of weakness are, whether it is vegetation growth in an easement or equipment in pre-fail condition, presents an opportunity to do precisely targeted prevention. With this information, run-to-failure or random maintenance becomes unnecessary. Instead of doing rotational preventive maintenance geographically over large areas, linemen now are armed with specific preidentified points on which to work. This results in less preventive maintenance. For HEMC, the reliability program yielded 92 preventive repairs. Each one of these represents a future outage. This is a manageable amount of predictive maintenance work that can be accomplished in several months.

Next Phases

The second and third phases of the reliability program are underway and aimed at helping the HEMC system catch up from historical vegetation challenges and deteriorating legacy equipment. To that end, the Easement Clearing Initiative continues, majorly impacting the large poultry farms that rely on electric controls and motors, whereby eliminating tree-touch outages can significantly improve farming operations.

In addition, by using outage management system intelligence, challenging and problematic single-phase circuits have been identified for Exacter patrols and IR camera assessments. These activities already are underway. The goal of this is to create a level set at HEMC, where maintenance crews can start each year with a clean slate, responding and maintaining current issues instead of problems of the past.

Significant Results

In 2017, HEMC’s SAIDI was 195 minutes. After the first year of the reliability program, in 2018, SAIDI was reduced to 158 minutes. At the halfway point of 2019, HEMC’s SAIDI was projected to be 98 minutes — a 50% reduction! According to DRG, the Exacter findings and repairs resulted in more than 6000 different customers being spared 80 minutes of outage interruption. A key part of the reliability program, the targeted vegetation management program is credited with much of the reliability gains.

Widening the failure spectrum to include equipment exhibiting pre-fail characteristics raises the bar on what is acceptable and unacceptable on the system. If deteriorating equipment consistently is identified and removed, reliability will improve automatically. If easements and tree touches are better identified and managed, outages will be reduced. At HEMC, having the conditions-based intelligence to know where points of risk are located will continue to be a foundation of continuous improvement for the coop’s members.

For more information:

Davey Resource Group Inc., A Wholly Owned Subsidiary of the Davey Tree Expert Company | www.davey.com/davey-resource-group

Exacter | www.exacterinc.com