According to the International Energy Agency [1] in 2021 the electricity demand is anticipated to grow by 3% (around 700 TWh) in total, which means that global demand would be higher than in 2019.

The greatest uncertainty for electricity demand in 2021 is the further development of the Covid-19 pandemic, the measures taken by governments to prevent it spreading and the availability, speed of distribution and effectiveness of vaccines. This will affect the commercial and services sector, which was hit hard by repeated lockdown measures towards the end of 2020.

Additionally, economic prospects depend on government stimulus packages and their success in triggering new investment and supporting businesses that have experienced economic pressure in 2020.

As far as Europe is concerned, already in 2030 the ten-year development plan of the EU grid foresees 58% [2] of electricity from renewable sources in the EU mix to be tackled with 166 new grid development projects and 15 storage projects, for a total investment of 144 billion Euro, which will result in annual savings of from 2 to 5 million Euro, due to the cut in generation costs and due to the greater flexibility of the system.

For example, Germany alone will need a capacity of between 235 and 276 GW of renewable energy by 2035 (more than double the 116 GW at the end of 2018) and over the next few years German Ministers announced they must build over 7,500 kilometers of transmission networks, including strengthening of interconnectors with European neighbors.

Electricity grids will therefore have to equip themselves to instantly convey the production of energy from the wind and the sun (e.g. Baltic Sea or southern Europe) to the areas where this electricity is needed (e.g. Rhine Valley and South Germany), even thousands of kilometers away.

We need shifting power across EU from where it is not needed to where it is and electricity storage, flexible demand, interconnectors could help to cut the costs of the green transition.

Typical drivers of this phenomena are the political change toward green energy production (i.e. EU Green Deal and the Biden administration’s clean energy drive) as well as the differential cost of energy between countries/areas that make viable and desirable the interchange of energy in parallel or in substitution of new generation plants.

Power generation from renewable energy sources and interconnection among networks are, in fact, the two main areas where energy links is developing massively and as such are driving technological evolution.

Cable market is one of the hot sectors in the clean energy transition, as demand for products such as undersea HV lines leads to order backlogs of 2 to 5 years for cable makers portfolios.

Furthermore, the consequences of climate change that bring more frequent and intense storms, floods, heat waves, fires and other extreme events are under the eyes of all, consequently the use of underground cable networks will grow as the latter are more resistant to these climate-related risks.

HDVC Cable Revival, Real World Underground Demonstrations

HVDC cable systems are used worldwide to transit high power over long distances in situations where HVAC connections are not feasible or not economical convenient.

The number of HVDC interconnectors in the construction stage is larger than ever before. Also, there are many projects in progress at various preliminary stages (planning, studies etc.), and they are typically very long and with higher power ratings, thus pushing voltages to new levels with new cable technologies.

Demand for interconnectors is rising as the EU and other countries work to develop more flexibility in their grid systems, boost cost border electricity trade, and connect new renewable power to the cities where it is in demand. The market for interconnectors is expected to grow 14% per year over the next decade according to different consultants.

HVDC connection in EU are mainly used as interconnectors in the Mediterranean area and both as interconnectors and connection of offshore windfarms in the North Sea (see Fig. 1).

Background

At the September 2014 symposium that precede the opening of HVDC new test lab in CESI-FGH Mannheim, different international TSO emphasized a lack of multi-year experience with HVDC technology. Among European TSOs, TERNA also pointed out shortcomings and did played an important role for the development of the reliability of XLPE extruded cable with the Polarity Reversal tests performed [3] up to 350 kV at FGH laboratories in Mannheim, see Fig.2.

From this point of view, CESI’s new testing facilities, with 60 m x 25 m x 21 m (L x W x H) in size, with 3 independent areas (25 m x 20 m each), each one with a dedicated DC generator, can support through flexible and professional testing services the increase of reliability of the grids.

The GTSO project

To have higher thermal and electrical performance (e.g. operating temperature and higher power deliverable), the German Transmission System Operators (GTSO), in the frame of the Energiewende, was looking for the first set of cable manufacturers able to supply at least 3000km of 525 kV DC extruded cables systems.

In order to fulfil this need, an ad hoc qualification process was established by GTSO (Type Tests and Pre-Qualification Tests) where CESI (at that time) was deeply engaged and 4 cable loops were under test in FGH. For the first time ever for HVDC cable systems, the cable loops of the PQT were not tested on the floor of a laboratory [4] [5] but mainly underground, representing real network situations like urban tunnel, pipelines and joint bays, [6] see Fig.3.

Transient Over Voltages (TOV)

Recently KEMA Labs Mannheim laboratory was requested to perform a feasibility study on the possibilities of setting up test circuits that could enable laboratory testing of full-scale HVDC cable systems up to 525 kV according to the above-mentioned TOV. The aim was to verify the performance of the HVDC cable system to withstand these stresses, which are of non-standard nature e.g. during pole-to-ground fault, pole to pole fault, faults on AC side etc.

These requests are addressed to the enhanced capability to withstand electrical transients, giving higher confidence for all transient phenomena occurring in HVDC schemes.

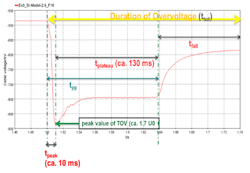

In case of failures in an HVDC cable grid, two categories of overvoltage stresses are expected to occur. Zero-crossing damped oscillatory discharges in the failing pole (see Fig. 6) and a very slow long impulse dynamic voltage stress (see Fig.7). Very slow means slower than standard switching impulses in comparison to standard test setup as could be seen in relevant CIGRE and IEC standards [10].

Since already a number of test specifications including these type of TOV with different values for the voltage magnitudes and time parameters have become known, it seems necessary to define proper requirements in case it is intended to standardize these tests, e.g. tolerances on test parameters shall be provided.

Furthermore, KEMA Labs, who is fully engaged in this project in different areas, considers very important that the required impulses shall be produced in typical HV cable testing laboratories without excessive efforts to facilitate the introduction of these new TOV stresses in the frame of the standardized types of tests on HVDC cable systems.

Conclusions and outlook

In recent years HVDC solutions are having higher preferences not only for submarine cables but also for land applications especially for long distances.

To have higher thermal and electrical performance TSOs are looking for a new class of extruded cables; in fact, in particular German TSO are looking for the first set of cable manufacturers able to supply 525 kV DC extruded cables systems.

The request of German TSO's not to test on the floor of a laboratory but to have a replica of a real underground network layout, with 525 kV DC cables and accessories to be able to withstand each specific environmental installation peculiarities, has greatly increased the level of complexity of the long-term tests, both in terms of test modalities and the management of the tests themselves.

The experience gained during the execution of the PQT gave quite positive feedback on the behavior of the cable system, increasing the expected reliability of the connections in HVDC. Outcomes of such tests cannot be disclosed without agreement among all the parties involved.

It’s evident that successful passing of the PQT will give confidence to manufacturers of new HVDC voltage level for extruded cables systems (with different type of cable and accessories) to become qualified for 525 kV DC transmission projects, not only for German TSOs but worldwide.

It can be easily forecasted that GTSO qualification procedures will become a similar milestone for the HVDC cables market like it happened for the BEWAG project for HVAC extruded cable systems in early ’90.

The positive experiences gained from the tests carried out for the GTSO project and the growing requests from European and Far East manufacturers and Utilities, have prompted KEMA Labs to invest in the Milan laboratory (called the Big Hall “il Salone”) with substantial interventions that have made it equipped now with two test lines for HVDC cable systems up to 525kV (both terrestrial and submarine cables), according to the most up-to-date international requests.

Recently, it is observed an increase of requirement coming either from equipment manufacturers or from grid operators. These requests are addressed to:

· verify the possibility of reversing the flow of energy circulation in the event of varying needs of adjacent markets, and

· withstand electrical transients, giving higher confidence for all transient phenomena occurring in HVDC schemes such as during pole-to-ground fault, pole to pole fault, faults on AC side etc.

With the appearance of technical specifications with different values for voltage quantities and time parameters, it seems necessary to define the requirements in the event that it is intended to standardize these new types of tests, e.g. tolerances on test parameters, calibration procedures and so on must be provided.

About CESI and KEMA Labs

CESI S.p.A (Centro Elettrotecnico Sperimentale Italiano) is a world-leading technical consulting and engineering company in the field of technology and innovation for the electric power sector. Through its Division KEMA Labs, CESI is the world leader for the independent Testing, Inspection and Certification activities in the electricity industry. With a legacy of more than 60 years of experience, CESI operates in 70 countries around the world and supports its global clients in meeting the energy transition challenges.