Industry Challenge

As the requirements for T&D reliability and resiliency increase in the face of continued pressure on utilities to lower operating and maintenance costs, advanced monitoring technologies are a promising solution. Technologies must be easy to deploy and integrate into present systems while, at the same time, provide pertinent information that can inform decisions.

EPRI’s Response

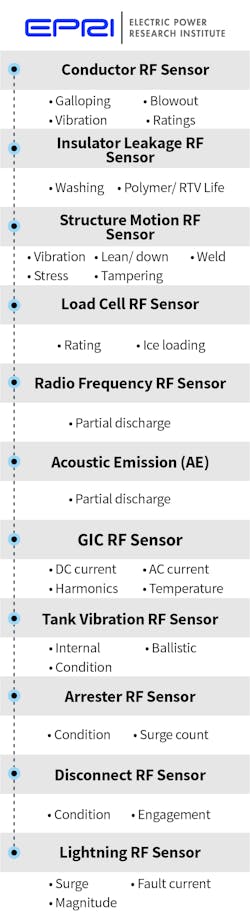

In 2003, the Electric Power Research Institute (EPRI) started to develop a toolbox of radio frequency (RF) sensors to meet this challenge. Each of the RF sensors developed addresses a specific asset or issue, is easy to install, is self-powered, and contains on-board algorithms to convert measured data to actionable information. The sensors are intended to have decade-long life and a lower cost.

Progress, Results, & Next Steps

EPRI has created 12 RF sensors for overhead lines and eight for substations, with still more concepts in development. Many of these sensors measure parameters that cannot be measured with wired technologies—for example, geomagnetically induced currents (GICs) that flow through energized conductors.

Some of the RF sensors have been designed to be installed under energized conditions, such as with a hotstick, and are power-harvesting. All of EPRI’s RF sensors can be integrated into a single RF base station that can be solar-powered and communicate using various options, such as cell phone modems, DNP3, or Modbus. A graphical user interface visualizes the information for different stakeholders and creates customizable alarms.

To date, more than a thousand sensors of different types have been demonstrated at EPRI-member utilities in more than 50 pilot projects. Many of these pilot projects have resolved difficult questions, such as determining when to wash insulators, why conductors gallop, and whether partial discharge (PD) activity is occurring on bushings.

Among the key lessons learned are that one needs to have experience from many sensors and that multiple revisions are needed to become confident that the sensors are reliable and yield relevant actionable information.

How to Use the Research

T&D utilities experiencing problems that must be diagnosed and solved in the field should consider whether RF sensors can help. Some examples include:

• Multiple utilities have been faced with contamination substation outages, and RF leakage current sensors have been deployed to provide a deeper understanding and alert crews when to wash the insulators.

• A utility concerned about the reliability of transformer bushings quickly deployed the AE sensors to continuously monitor for PD. The PD was found to be correlated with loading.

• When deploying an advanced transmission line design, a utility wanted to be confident of the field performance. It deployed galloping, blowout, arm vibration, weld-stress, and leakage current sensors to confirm the design in the field.

How to Get Involved

Utilities interested in solving challenges in substations and on overhead lines might consider deploying appropriate RF sensors from the toolbox to obtain insights and actionable information. These pilot projects will not only help address the issue at hand, but will allow the industry to obtain more experience with this new technology, improving performance and reliability.