Distribution utilities are showing an increasing interest in power factor correction (PFC) as a way to increase system capacity, improve quality of supply and reduce system losses, thus increasing overall distribution network efficiency. As a result, PFC plays a significant role in network operations.

The utility’s PFC base is typically based on a concept similar to the mix of distributed generation now being connected to distribution networks. At the majority of today’s utilities, PFC is achieved by installing capacitor banks either on medium- or low-voltage networks, but distributed PFC offers an alternative approach: It can reduce energy losses while increasing the capacity of a network when the reactive power compensation is next to users.

Motivation for Decentralized Installations

When electricity demand increased and the power factor reached the desired level on Mashhad Electric Energy Distribution Co.’s (MEEDC’s) distribution network in Iran, additional investment in PFC — required to be installed on the low-voltage network — began to show diminishing returns. This prompted the utility to begin examining the advantages of deploying decentralized PFC equipment.

The poor power factor on MEEDC’s distribution network was associated with fluorescent lighting, energy-saving lamps and air-conditioning units. A recent survey conducted in the city of Mashhad revealed that a residential customer uses at least seven fluorescent lamps. The resulting low power factor can cause overheating of inductive equipment and premature failure as a result of excessive voltage drop and losses on the distribution network.

There are several methods of PFC, each of which has its advantages and disadvantages. If centralized reactive power compensation is employed, only a partial benefit is achieved. The installation costs in this case are lower than the decentralized method, and the power factor at the point of common coupling is kept above a permissible level. However, the reactive power has to reach a point where a centralized reactive power compensator is needed, so the network losses remain as if there was no power factor compensation.

As a result, MEEDC considered a new approach, exploring the advantages of deploying PFC on its low-voltage network where the PFC would be positioned close to customers’ terminals. One of the utility’s main obstacles with distributed PFC was the lack of an appropriate-sized standard capacitor that could be installed inside the meter cover. The utility determined that the capacitor specifications had to include the smallest possible dimensions, easy installation and safe operation.

Course of Action

To meet these demanding requirements, MEEDC engineers developed a series of PFC capacitors that would fit inside the meter cover. The capacitors were designed for single-phase applications with a permissible voltage of 230 V on a 50-Hz network.

With the distributed PFC capacitors now installed, the utility’s electric energy consumption is optimized, which ultimately leads to reduced energy consumption and greenhouse gas emissions. PFC capacitors increase the system capacity because of the reduction in total current drawn from the distribution network. One major drawback of this approach is

harmonic resonances that need be taken into account.

In addition to their diameter matching the size of the meter case, the PFC capacitors offer a variety of customer benefits. Utility technicians can install the capacitor easily without the need for special training, and the customers’ 230-V voltage level is stabilized.

Pilot Field Trial

To check the feasibility of decentralized PFC, MEEDC conducted a pilot field trial in the Hashtabad region:

- 73,000-sq-m (785,765-sq-ft) trial area

- 431 residential customers

- Eight commercial customers

- Four public feeders

- Three express feeders

- One 800-kVA high-/low-voltage distribution transformer

- 1,600-A automated distribution switchgear.

Data management and analysis were performed using TDL101 data loggers from Mashhad Tadbir. At the start of the project, all electricity meters in the region were read, and the data loggers were set to record the electrical parameters simultaneously. Then, 13 days later, the electricity meters were read again, and the PFC capacitors were installed inside more than 430 customer meters over a six-day period.

The dedicated PFC capacitor installed in each customer’s meter was rated at 12 µF, and during the test period, the power factor reached 0.95 compared with the 0.85 recorded before installation of the capacitor. For the field trial, MEEDC staff provided and installed the new capacitors with the service connection remaining live in the utility’s existing meters, which were manufactured by several companies including Ski and Pauraad, under license from ABB and Elster through their joint solutions.

Although the capacitors developed in the field trials were 12 µF, the capacity has been decreased to a 9-µF capacitor because of the Ferranti effect and distribution network resonance. Therefore, every single-phase meter currently ordered by MEEDC will include a 9-µF capacitor. Industrial customers with a three-phase supply are required to provide their own means of compensation by selecting the most appropriate method for PFC based on energy consumption, tariff metering, investment payback and emission reduction.

Metering Standards

All meters manufactured in Iran are the solid-state type or smart meter, and come with a dedicated capacitor installed inside the cover, under the supervision of MEEDC. To date, Behineh Sazan Toos Co. — a manufacturer of all types of multi-tariff meters, under license by the Hexing Electrical Co. — has supplied MEEDC with more than 50,000 meters equipped with PFC capacitors that, in common with all the metering equipment, are compatible with International Electrotechnical Commission standards and come with a five-year guarantee and a 15-year after-sale service agreement.

Investment Payback

The installation of PFC equipment is a widely recognized way to reduce electricity costs as a result of reducing energy losses and benefiting the environment. However, because of the length of the payback period for such equipment, a utility should examine each situation on a case-by-case basis.

The MEEDC project resulted in a very short investment payback period. For example, a total annual savings of around 200 MWh can result in a cost savings of some US$170 million, savings that can then be shared between the utility and its customers. Additionally, the benefits of decentralized PFC extend beyond these cost savings. Decentralized PFC reduces the current loading on distribution equipment so utilities can defer the capital investment required to reinforce the power system and expand grid capacity. Furthermore, the application of PFC on all networks helps to improve and maintain the network voltage.

Benefits for Utilities and Customers

The new application developed by MEEDC reveals that

decentralized reactive power compensation on some networks can bring benefits to both utilities and customers:

- Power factor improvement in substations (from 0.83 to 0.95 in MEEDC’s case)

- Improved voltage profiles in medium- and low-voltage feeders, without creating overvoltages

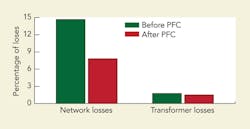

- Transformer losses reduced by 0.25%

- Distribution system losses decreased by some 50%

- Increased system capacity

- Deferment of capital investment as a result of increased capacity

- Improved utilization of distribution network equipment

- Improved system efficiency, further resulting in environmental benefits

- Reduced operating costs.

Ali Saeedi ([email protected]) is the managing director of Mashhad Electric Energy Distribution Co. Saeedi is a member of the Iranian Association of Electrical and Electronics Engineers, National Committee of Reliability, and the Electrical Distribution Companies Association. He also is an author of four books and several conference papers. He received BSEE and MSEE degrees from Ferdowsi University of Mashhad, Iran.

Morteza Hossein Pourarab ([email protected]) has worked in the research center of Mashhad Electric Energy Distribution Co. since 2009 and participated in several R&D projects. His current research interests are harmonic distortion management, power-quality monitoring, distributed energy systems and energy management. He received a BSEE degree from Ferdowsi University of Mashhad, Iran, and a master’s degree in electrical energy management from Amirkabir University of Technology in Iran.

Mohsen Zabihi ([email protected]) is vice president of Mashhad Electric Energy Distribution Co. and the deputy supervisor for planning and operations. Zabihi, who is the author and coauthor of two books and several technical papers, is a member of MEEDC’s R&D committee. He received a BSEE degree from Ferdowsi University of Mashhad, Iran.

Saeed Alishahi ([email protected]) is manager of Mashhad Electric Energy Distribution Co.’s R&D center and is a member of the R&D committee. He is responsible for all research projects and activities at MEEDC. He holds a BSEE degree and has authored more than 50 papers and articles in the field of electricity distribution.

Companies mentioned:

ABB| www.abb.com

Behineh Sazan Toos

Elster| www.elster.com

Hexing Electrical Co.| www.hxgroup.cn

Iran Transfo| www.iran-transfo.com

MEEDC| www.meedc.ir

Mashhad Tadbir

www.mashhadtadbir.com