Both AC and DC UHV systems are necessary to handle the increase in electric energy consumption and to back up the existing transmission system. They are, in effect, the highest density, highest efficiency electric power super highways. Bulk power transmission over big distances is – naturally – a topic for big countries. Therefore, UHV installations have been built in countries such as China, Russia, India, Canada, South Africa and the United States. However, the ongoing urbanization as well as the change in energy production to renewables and offshore power now make the UHV technologies a topic virtually everywhere.

Ultrahigh-voltage AC grids require electromechanical switchgear that can cope with the switching demands for normal operation, for protection in the event of a short circuit and for maintenance and revision purposes. ABB's portfolio comprises AIS LTBs (air-insulated switchgear live tank breakers) and DTBs (dead tank breakers), and hybrid switchgear and GIS (gas-insulated switchgear) portfolios, which each have their specific characteristics to best meet customer needs. Designing and building HV switchgear capable of meeting the stringent safety, performance and reliability demands for UHV power systems is a significant challenge, but one where ABB has consistently taken the lead over the past 50 years through technical innovation and close dialogue with the utilities.

A key aspect of ABB's successful leadership in supporting UHV power system implementation is the strength and flexibility of its modular design and production approach for all its HV switchgear breaker solutions including LTB, DTB, hybrid and GIS. ABB has the strongest single-element interrupters for both livetank and metal-clad solutions, as well as the world's most comprehensive range of breaker operating mechanisms, enabling ABB to rapidly develop reliable, high-performance switchgear to meet customer's needs.

ABB's leadership in switchgear design extends beyond interrupters and operating mechanisms to other core components for UHV technology, such as composite insulators using silicone rubber for bushings, metal varistor technology for overvoltage protection, nonconventional instrument transformers and sensors for current and voltage measurement.

Air-insulated UHV technologies

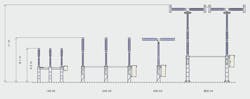

Electrical grids and the corresponding substations are often air-insulated – the high voltage is kept away from both the ground and people by distances of tens of meters ➔ 1 – 2.

The strength and reliability of ABB's live tank interrupters and drives – built on single-element interrupters up to 300 kV, 5,000 A, 80 kA and able to operate in climate extremes from – 60°C to + 50°C – provide the foundation for providing the most reliable and proven live-tank switchgear solutions up to 1,200 kV and even up to 80 kA. By coupling knowledge and experience in composite insulators and the ability to integrate advanced technologies such as ABB's fiber optic current sensors, ABB can offer the safest, most reliable and most compact UHV AIS solutions for both AC breaker and DC switching applications. ABB live tank solutions are supporting and protecting UHV power systems across the world in China, India, Canada, Russia, the United States, Ukraine and Venezuela, among many other locations ➔ 4.

4 Comparison of the heights of different current breakers

The backbone of ABB's UHV dead tank circuit breakers are single-element interrupters rated up to 362 kV, 63 kA and 5,000 A. Utilizing tank heaters, the circuit breakers and drives are capable of operating in climate extremes from – 50°C to + 40°C. The interrupters and drives provide the foundation for the most widely installed and proven dead tank circuit breakers up to 800 kV. For the future, similar interrupters and drives utilized in GIS for the Bina Substation project in India, provide the foundation for extending the dead tank circuit breaker capabilities up to 1200 kV. In 2000, ABB was the first to install an 800 kV dead tank circuit breaker. Since then, the 800 kV dead tank circuit breaker has been supporting UHV power systems worldwide, notably in China, the United States and South Africa.

Gas-insulated UHV technologies

Metal enclosure and SF6 gas insulation enable the development of more compact high-voltage switchgear. One of ABB's predecessor companies introduced GIS technology to the market in 1965 with the first 170 kV GIS underground substation being installed in the Zurich city center in Switzerland the following year. In 1976, ABB delivered the first 500 kV GIS to Claireville, Canada.

With the installation of the world's first 800 kV GIS in South Africa in 1986, ABB has proven its technology leadership at the ultrahigh-voltage level. This so-called alpha substation has been in operation for more than 20 years without failures or unplanned interruptions.

The world's first 1,100 kV AC grid in China has been under successful commercial operation since it was energized in 2009. For this grid, ABB developed a complete GIS components portfolio, including circuit breakers with closing resistors, disconnectors, earthing switches, current transformers, busbars, bushings and insulators, and tested it together with the Chinese switchgear manufacturer Xian Shiky. ABB shipped the core components for the 1,100 kV hybrid GIS installation to Jingmen substation and continues to supply core components such as spacers, interrupters and circuit breaker drives to several Chinese switchgear manufacturers for ongoing and further extensions of the 1,100 kV grid in China ➔ 3.

3 1,100 kV GIS for China

In India, an ultrahigh-voltage grid is also in the testing, planning and execution phase. The execution of this 800 kV AC transmission grid comprises several substation tenders including ultrahighvoltage GIS and AIS switchgear. ABB is renewing its 800 kV GIS design, which has been shipped to this alpha substation to fit it to today's standards for routine and type testing and to upgrade to state-of-the-art technology. Part of this renewal program is to perform a complete type-test series according to the latest standards and the customer Powergrid of India.

The 1,200 kV AC transmission grid in India is now in its testing phase and Powergrid of India has set up a 1,200 kV test station at Bina to allow manufacturers to install and test their UHV equipment. The test station is powered by transformers connected to the 400 kV grid on both ends of a short overhead transmission line. This allows power flow through 1,200 kV equipment to ensure real test cases for the equipment ➔ 5.

5 Power flow from Satna to Bina will be diverted via a 1,200 kV test station.

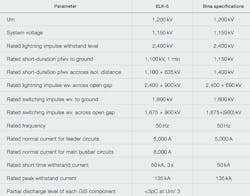

ABB has agreed to invest in a hybrid GIS test pole to be installed and tested at Bina test station. A GIS is named "hybrid" if the busbars are air-insulated but all other equipment such as circuit breakers, bushings, busducts, connecting elements, manually operated disconnectors, current transformers and PD sensors are of gas-insulated design. For this test pole the GIS components of ABB's ELK-5 GIS are applied, as the type tests conducted on it already cover the specified values requested by Powergrid of India ➔ 6.

6 Comparison of main equipment ratings for ELK-5 and Bina requirements

The 1,200 kV hybrid GIS test pole is being assembled and factory tested in ABB's switchgear factory at Vadodara, India under witness of Powergrid of India. Installation and commissioning took place in February 2013.

Leadership in switchgear

ABB is the technology and market leader in most UHV AC switchgear technologies and continues to invest in the development of new products, upgrades and higher voltage levels, and pursues market opportunities for both AIS and GIS substations.

The latest UHV development in AIS technologies is the installation of a 1,100 kV bypass circuit breaker. In GIS technology, the upgrading of ELK-5 equipment to the 1,200 kV voltage level used in India and the corresponding hybrid GIS pilot installation at Bina substation are both ongoing.

Walter Holaus

ABB Power Products, High Voltage Products

Zürich, Switzerland

[email protected]

Michael Lane

ABB Power Products, High Voltage Products

Mount Pleasant, PA, United States

[email protected]

Richard Thomas

ABB Power Products, High Voltage Products

Ludvika, Sweden

[email protected]