The two main operational stresses experienced by HV AIS equipment are current and voltage. HV equipment must also not only manage normal voltages and currents, but – most importantly – must fulfill required safety and security concerns when faults and operational extremes occur on the electric power network. Circuit breakers must be able, on command, to interrupt currents up to full short-circuit ratings within milliseconds and without failure. Surge arresters must limit overvoltages within microseconds. Voltage and current transformers must continually provide accurate measurement data on the load and status of the power system. Additionally, apparatus like circuit breakers are required to perform their switching operations up to several times a day after extensive idle periods.

Power utilities and society rely on the equipment in electric power network to withstand these extremes, so that electricity remains available when it is most needed. HV AIS equipment must therefore also withstand a wide range of environmental stresses including extremes in ambient temperature, humidity, aerial pollution (natural eg, salt or manmade), severe weather (eg, cyclones, hurricanes) and even seismic events.

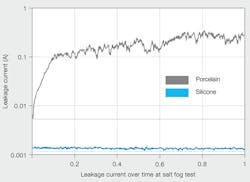

Selecting, developing and incorporating the most appropriate materials for managing the operational and environmental stresses HV AIS equipment must withstand is fundamental to the enduring success of ABB's HV AIS solutions. For example, the use of composite silicone rubber insulators instead of porcelain ones lowers equipment weights by 20 to 40 percent. They also inherently increase safety by being nonshattering and also improve seismic and pollution withstand performances. The significantly lower leakage current of silicone rubber compared with porcelain insulators during a salt-fog test is shown in ➔ 1. Such insulators reduce the weight of circuit breakers, instrument transformers and arresters, and make substations significantly safer and more reliable. ABB has delivered over 60,000 silicone rubber composite insulators worldwide ➔ 2.

With respect to internal insulation, ABB's SF6 live tank breakers are designed for ambient temperatures down to – 60 °C, which results in using the least amount of SF6 per interruption rating of any breaker design available. The use of quartz sand in combination with oil as the insulating medium in its IMB current transformers (CT) significantly reduces the volume of oil required; for example, using this technique the oil volume is reduced by about 425 liters for the 550 kV IMB CT. In addition the quartz sand provides the IMB greater strength to withstand the high mechanical stresses that occur during short-circuit conditions in the network. Another recent addition to ABB's innovations in this area is the dry pre-assembled cable termination. This technology eliminates the use of oil in cable terminations and makes their installation easier and quicker.

Optimization of ABB AIS designs is also clearly demonstrated beyond materials selection. ABB is the first and only HV live tank breaker supplier to not require grading capacitors at 550 kV up to 63 kA. This significantly reduces the weight of the circuit breaker and also dramatically reduces leakage currents across an open breaker and eliminates the risk of ferroresonance in the power network. ABB also has the only 800 kV live tank breaker with only one spring-operating mechanism per phase, which dramatically reduces the complexity of the circuit breaker control and operation, improving overall reliability and providing the optimal device for controlled switching at the highest voltage levels.

Other highlights of ABB's design innovations in AIS can be seen in the following applications:

- Overvoltage control - ABB has developed and produces its own metal-oxide varistor blocks for surge arresters that provide the maximum protection by triggering at the lowest overvoltage protective levels for the full energy dissipation requirements. Additionally with the high field strength of ABB's metallic oxide varistors, material, weight and size of arresters is reduced ➔ 3.

- Enhanced power quality - ABB's capacitors and capacitor banks designed in modular banks cater to the widest range of power quality applications from power factor correction to harmonic content filtering.

ABB is a pioneer in controlled switching and today has the largest installed base of controlled switching circuit breakers (over 3,700 installations accumulated over the past 25 years). The primary benefit of controlled switching is to minimize the level (size) of transients propagated on the power network due to normal switching of capacitors, reactors, transformers or lines in the power system, and ABB offers the largest application range.

Functionally focused flexibility

Functional modularity is a defining aspect of ABB's ability to provide the widest range of HV AIS products and solutions.

An example of the advances in HV AIS equipment technology gained by ABB through dialogue with customers is the development of the disconnecting circuit breaker (DCB).

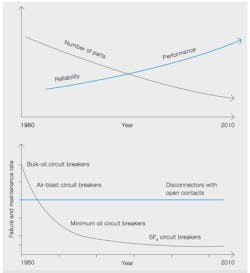

While developments in circuit breaker technology throughout the past 70 years has led to continuously higher reliability and lower maintenance, disconnector technology has remained relatively unchanged. This resulted in ABB's live tank breakers (LTBs) providing higher reliability and having lower maintenance needs than any available disconnector and spurred ABB to develop the DCB. In a DCB, the disconnecting function is integrated with the circuit breaker and therefore the need for separate disconnectors is eliminated. Additionally the high electrical endurance and voltage withstand strength available in ABB's live tank breakers, coupled with the added safety and pollution withstand of silicone rubber composite insulators, has put ABB in the unique position of having the world’s largest range of DCBs, that is from 72 to 550 kV and up to 63 kA ➔ 4.

DCB solutions provide many savings and benefits for power utilities, including reduced substation footprint, simplified substation design, higher power network availability and significantly lower total life-cycle costs ➔ 5.

Success story: Statnett's substation in Grytten

- 30 percent reduction in substation space

- Maintenance intervals increased from three to 15 years

Statnett's Grytten substation is a key component of the Norwegian regional grid, and the sole electrical supply point to the area around Åndalsnes. The substation was built in 1965 and progressively built up as a dual busbar system with an auxiliary busbar connecting four line bays and two transformer bays. The dual busbar system was necessary to guarantee uninterrupted service during transformer and circuit breaker maintenance. The final station had 81 single-pole disconnectors for facilitating maintenance.

Disconnectors and older circuit breakers were maintained at three- to five-year intervals. Moreover, the disconnector main contacts were inspected using thermal imaging on a yearly basis to detect any overheating tendencies.

In Statnett's maintenance plans, the useful service life for disconnectors was set at 35 years and the disconnectors at the substation were scheduled for replacement. It had also been decided to replace the substation's control equipment.

During subsequent planning, the question came up as to whether the devices should be replaced one at a time or whether a new, all-embracing solution should be considered. Statnett had studied the solution at Norsk Hydro's facility in Sundalsöra and looked at a solution with disconnecting circuit breakers (DCBs).

Availability calculations showed reduced annual downtime with the DCB. To further reduce maintenance needs, Statnett chose MotorDriveTM as the operating mechanism for the disconnecting circuit breakers. The optimized design with just one moving part in the operating mechanism reduces mechanical stress to a minimum. Electronically controlled operation is accom- plished without mechanical stopping, which means very quiet operation.

In addition, new current and voltage transformers and surge arresters were provided with newest ABB designs with ABB silicone rubber insulators.

The new switchgear occupies about 30 percent of the space of the old switchgear. The freed space can now be used for any other needs that may arise in the future.

In practice, the only devices that require maintenance are the disconnecting circuit breakers. A 15-year maintenance interval was proposed for full inspection. Every other year, visual inspections of the devices will be conducted, but without removing equipment from service.

Statnett has obtained new switchgear based on modern technology with a minimum of maintenance requirements. The substation, which is situated at an important location in the grid, has high availability and is very operationally friendly.

The short installation time and the well-planned switchover of operations enabled the entire modernization project to be conducted without interrupting service to customers.

Future technologies today!

ABB continues to lead in HV switchgear technology solutions, making further advances in reduction of materials, increases in functionality and reduction in environmental impact. Examples of futuristic technologies from ABB include the following.

Motor drive

First released in 2000, over 500 highvoltage breakers with a motor drive and based on the live tank breaker and hybrid technology platform have been delivered. The motor drive provides the optimal operating mechanism platform for future circuit breakers with IEC 61850-9-2LE process bus control.

Fiber optic current sensor (FOCS)

When integrated with the disconnecting circuit breaker, FOCS provides a footprint reduction of over 50 percent compared with the conventional solution of live tank breakers with disconnectors and current transformers ➔ 6. The solution eliminates a large part of the conventional wiring, secondary safety risks with conventional CTs, and has no saturation effects. In addition it is compatible with the IEC 61850-9-2LE, thus providing greater flexibility in substation protection configuration and operation through advanced process bus communication of current measurement data.

The LTA, which is the first high-voltage circuit breaker to use carbon dioxide (CO2) as an insulating and arc-extinguishing medium, offers a suitable alternative to conventional SF6 gas breakers. The LTA provides a reduction of about 18 percent or 10 tons in CO2-equivalent global warming impact over an approximate 30-year product life cycle. It is currently available for 72.5 kV networks as a conventional circuit breaker as well as a disconnecting circuit breaker.

Numerous advantages

By utilizing modern material and design methods, high-voltage air-insulated switchgear from ABB helps utilities and industrial customers worldwide to reduce costs and at the same time reduce environmental impact. The decreased size and weight of equipment also lowers transport costs and impacts, as well as requirements on foundations and installation work. The equipment's additional integrated functionality (such as disconnecting circuit breaker and integrated fiber optic current sensors) in combination with the latest designs of capacitors, voltage transformers, arresters as well as control functions, offers compact designs that reduce space requirement of substations while enhancing reliability and safety ➔ 7.

Richard Thomas

Hans Matses

ABB Power Products, High Voltage Products

Ludvika, Sweden

[email protected]

[email protected]

----------------

Further reading

- ABB Controlled Switching Buyers and Application Guide

- ABB Live Tank Breaker Application Guide

- ABB Disconnecting Circuit Breaker Buyers & Application Guide

- www.dcbsubstations.com