Transformers are critical parts of the electric power grid, and transformer components such as bushings and tap changers are crucial for ensuring the reliability and safety of transformers in service. Some functional moving and electrically stressed transformer parts are also subjected to outdoor conditions – for example, the air side of a bushing, which insulates the high voltage line from the transformer tank ground potential under rainy and polluted conditions.

Today's strong market requirement for reliable and safe electrical equipment has led to the emergence of breakthrough technologies for transformer components. For example, vacuum interrupter technology now represents a major trend for tap changers, because it substantially reduces the maintenance cycle by preventing contamination of the insulating oil, and slowing down its aging process.

Another major current trend in the transformer industry is dry bushing insulating technologies, combined with silicon outer insulators to provide the safest service conditions. Many other transformer components also contribute to reliable and safe service conditions of the equipment, including air breathers, which require supervision and maintenance to securely reduce moisture ingress in the transformer and tap changer oil.

Transformer customers today are not only demanding safe, reliable electrical equipment, but also cost-effective, overall solutions. Taking all of these factors into account is extremely important when considering an essential component of transformer design, such as the connection from the windings to the bushings, which very often dictates the overall size of the transformer (and thus its overall cost), as well as assembly time.

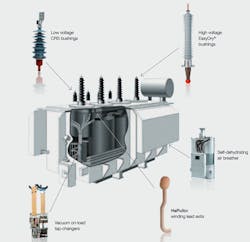

ABB, as a leading transformer component manufacturer is continually addressing major technology trends and market challenges in the transformer industry with innovative products that meet or surpass the demanding requirements of today's transformer customers ➔ 1.

1 ABB's latest innovative transformer components

New vacuum on-load tap changer portfolio

A tap changer can be considered a transformer's gear box. It connects or disconnects turns in the tap winding to maintain a constant voltage out of the transformer. Both mechanical and electrical challenges must be addressed when designing a tap changer, and demand for reduced maintenance has resulted in increased use of vacuum interrupter technology. Electrical arcing that previously took place in oil is now taking place in a vacuum interrupter, which prevents arcing from contaminating the insulating oil. Typical inspection intervals for vacuum interrupter technology are between 300,000 to 500,000 operations, compared with 100,000 operations for conventional, non-vacuum arc quenching technology. Additionally, there is no time limit set for maintenance with vacuum interrupter technology, while seven years is typically applied for conventional non-vacuum technology.

2 ABB's new vacuum on-load tap changer current portfolio

An overview of the current ABB vacuum on-load tap changer portfolio is shown in ➔ 2. The vacuum diverter switch tap changer types VUCG and VUCL have the advantage of being built in the same housing as ABB's conventional tap changer types UCG and UCL. Upgrading conventional units already in service, with corresponding ABB vacuum types, does not require any specific construction adaptations and makes the installation of new vacuum units straightforward. Similarly, since the vacuum selector switch tap changer type VUBB does not position the change-over selector outside the cylinder, its rotational symmetry makes installation extremely simple and easy. It is also fully insulated between the different phases, and therefore applicable to delta connection.

The new ABB vacuum reactance on-tank tap changer type VRLTC is fully insulated and mainly used for LV regulation – in this specific case, a reactor is used to bridge adjacent taps instead of a resistor. The unique electronic motor drive that controls the tap changer is fully integrated and can achieve one operation per second (compared to five seconds typically).

To secure reliable and safe service conditions, all new ABB vacuum tap changer types undergo a very demanding and extensive test program. For example, service duty test conditions – simulating typical service conditions – require 50,000 operations according to today's IEC and IEEE standard requirements. However, all new ABB vacuum tap changer types have been successfully service type-tested for 600,000 operations. In addition, several test objects of each type have been mechanically endurance-tested for over 1,200,000 operations under both warm and cold conditions, versus the standard test requirement condition of 500,000 operations.

Another technical challenge of vacuum interrupter technology is to ensure a long and reliable lifetime of the contacts, which weld due to the pre-arc created when the interrupter is closing. For a breaker, impedance from the whole grid limits the rise time of the current in the pre-arc, but in a tap changer it is only the inductance from one step in the tap winding that limits such a rise. The standard circuit used for tap changer service duty test doesn't produce this quick rise time, so a new test circuit had to be developed in order to better reproduce actual operating conditions. In this new test circuit, the new ABB vacuum tap changer types VUBB, VUCG and VUCL were tested for 600,000 operations at service conditions.

New self-dehydrating air breather portfolio

Air breathers are crucial transformer components that reduce the maintenance cycle of both the transformer and tap changer by limiting moisture ingress in both the transformer tank and tap changer compartment, respectively. A pipe system is in most cases connected from the top of the conservator to the breather, which is placed at ground level for easy access. Traditional breathers consist of a drying agent (such as silica gel) which dehydrates the air passing through, and retains the moisture. Regular inspections and replacement are needed to ensure the drying agent is not fully saturated, and can still absorb moisture.

The new COMEM self-dehydrating air breather (SDB) portfolio was developed to provide the safest and most reliable control of the air drying function, while lowering environmental impact and reducing overall maintenance costs ➔ 3.

3 COMEM's new self-dehydrating air breather portfolio

Saturation control and drying is automatic which drastically reduces maintenance time because the drying agent no longer has to be replaced. By using a patented double air breather tank system, it is ensured that the air intake in the transformer conservator is always passing through a tank with dehydrated drying agents, as the second tank is simultaneously regenerating. In other words, as one of the drying tanks is dehydrating, the other is used as the hydrator. This system guarantees a low humidity level for incoming air in the conservator. In addition, the entire SDB portfolio is smart grid enabled, with a digital output available.

New oil- and paper-free transformer bushing portfolio

The main function of a transformer bushing is to take the current on high potential through the transformer tank. ABB has been producing high voltage transformer bushings for more than 100 years, and today manufactures bushings in seven countries on four continents. The first dry, resinimpregnated paper (RIP) bushings were developed in the 1960s, and today ABB is a market leader for this type of product.

ABB is well-known for technical innovations that have set new standards in dry bushings technology. Nearly ten years ago, ABB recognized the market need for a new bushing technology that would provide safety and performance benefits of traditional dry bushings, but without the hermetically sealed protection on the oil side of the bushing which is required for long term storage, as is the case today for RIP bushings.

4 ABB's new EasyDry® bushing portfolio

Several years of R&D effort produced the new EasyDry® bushing portfolio. It is based on a unique resin-impregnated synthetics (RIS) technology, and is commercially available in a full range of standardized, oil-toair transformer condenser core bushings for 24 to 170 kilovolt (kV) AC applications ➔ 4. The RIS technology not only provides oil-free but also fine capacitive graded, paper-free bushings. Instead of using conventional paper insulation, the bushing's core is wound with polymeric (or synthetic) fabrics. EasyDry® bushings do not contain any water-absorbent materials, while maintaining the fire-resistant, explosion- proof characteristics of traditional dry bushings. This makes transportation, storage and installation much easier.

A major challenge during development was optimizing the curing process of the resin-impregnated, polymeric fabric wound condenser core, so that a crack and void-free bushing body could be produced faster than a conventional RIP core. ABB successfully established an optimized curing process.

The improved process means shorter process times and fewer materials and parts used in production (hence shorter delivery times), making EasyDry® bushings more environmentally friendly than any other condenser-core bushing technology available today. Thanks to the RIS technology, EasyDry® offers a unique combination of excellent performance and cost-effective products. Oil-free, explosion-proof, class-E insulation (ie, up to 120°C), very low tangent delta (or dissipation factor), and partial- discharge free up to double-service voltage are distinctive attributes that make EasyDry® bushings a perfect fit within ABB's broad product portfolio of environmentally friendly and high-quality components for power transmission and distribution equipment. They also contribute directly to today's higher network availability, reliability and safety requirement standards ➔ 8.

|

8 EasyDry® bushing success story in Indonesia As in many other countries in Southeast Asia, Indonesian electrical utilities are very price sensitive and would typically specify oil-impregnated paper (OIP) bushings rather than more expensive dry bushings, despite the benefits an oil-free product can bring. Indonesia can therefore be considered a very challenging market in which to introduce ABB new EasyDry® bushings. EasyDry® bushings have, however, the advantage of combining all the benefits of resin-impregnated paper (RIP) bushings but at a more attractive price than conventional RIP bushings, and at the same time enable simplified storage (no moisture penetration) and faster deliveries (more streamlined production). Indokomas, a local EPC, was commissioned to build a power substation to connect a brand new Honda Motor Company car factory to the 159 kV network owned by PLN, the main electrical utility in Indonesia. The substation project had a very short delivery time, ie, only six months from when the contract was signed to when the equipment had to be commissioned. Short delivery times were therefore crucial to meet the project timetable. With EasyDry® bushings, ABB was in a unique position to meet the challenge. Hand-in-hand cooperation between ABB factories in Vietnam (transformer) and Switzerland (bushings), as well as a well-coordinated effort from front end sales and regional marketing teams, finally made this breakthrough commercial installation a reality. The end customer received high-quality, maintenance-free bushings with more safety in service within an extremely short delivery time. This first successful project definitely provides ABB with a very good first reference installation for further market expansion of EasyDry® bushings in the region. |

New combined insulation transformer bushing

ABB also has a strong presence in the lower voltage transformer bushing market segment with an extensive product portfolio. A conventional non-condenser core bushing in that voltage range is typically composed of a conductor bolt (usually brass or copper), a porcelain insulating part and oil as the primary insulator. These so-called conventional porcelain bushings are low-cost components in comparison to the valuable assets in which they are fitted. A bushing failure – after either an internal breakdown in the main transformer unit (where the bushing then acts like an exploding "plug") or an internal bushing failure – can have dramatic consequences not only for the transformer itself, but also for its immediate surroundings. Shattered porcelain projectiles are likely to cause secondary damage to any other nearby equipment or people. Additionally, after such a dramatic failure, the insulating oil spreads out in small droplets, and combined with a secondary arcing can easily ignite and caused further collateral damage.

COMEM in Italy, an affiliate company of ABB, recently launched a combined insulation (combined epoxy resin and silicon or CRS) bushing, that addresses conventional porcelain bushing weaknesses by providing reliable insulation while substantially reducing the risk of collateral damage in the event of a bushing failure.

5 COMEM's new CRS combined insulation bushing

The CRS bushing has its conductor directly molded in a primary organic resin insulation layer, which is in turn protected by a shed-formed silicone rubber overcoat ➔ 5. This unique combination of insulation layers eliminates shattered bushing fragments (no porcelain) and drastically reduces the risk of fire (no oil), therefore greatly mitigating the risk of collateral damage after failure, while also providing excellent insulation properties in harsh environments (silicone rubber housing).

The CRS bushing consists of a full range of standardized transformer bushings for 24 to 72.5 kV AC applications, up to 5,000 A, with a level of partial discharges meeting the IEC 60137 standard specifications thanks to an embedded internal capacitance screen. With its exclusive combination of superior materials and robust construction, the CRS bushing addresses modern insulation requirements while simultaneously providing a safer and easier solution for handling, transporting and assembling bushing units.

Composite insulators with silicone sheds

Composite insulators offer superior insulation properties in a low weight, as well as non-brittle, and virtually maintenance free design. This insulation technology is rapidly increasing its market penetration, especially for critical components like high voltage bushings.

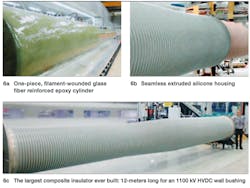

6 ABB's composite insulators

ABB is the technology leader in the market for hollow core composite insulators for ultra-high voltage (UHV) applications. The technology is well proven through demanding lab and field tests that often exceed standard requirements, and is supported by a unique service record from an installed base of 80,000 insulators. In-house production of the glass fiber tube and a one-piece tube design is essential in order to secure quality and enable short lead times ➔ 6a. To achieve the best tracking, erosion and durability performance, a high temperature vulcanized (HTV) silicone housing is used. The patented ABB helical extrusion process enables cost effective application of the housing on both small and large insulators, and directly on dry condenser bodies without any parting lines or joints ➔ 6b. Helical extrusion also eliminates the need for part-specific investments in casting tools, which significantly reduces lead times and costs in the development of new products.

ABB recently marked another outstanding achievement by developing the largest composite insulator ever built – 12-meters long – for a 1,100 kV HVDC (high-voltage direct current) wall bushing ➔ 6c. Despite development challenges, the project was completed in a record 10 months, from materials selection to final product design, including the installation of brand new production equipment.

New generation of winding lead exit system

Winding lead exit systems ensure the electrical connection between windings and bushings in high voltage power transformers. Conventional lead exits consist of insulating barriers made from cellulose-based molded parts. Manufacturing such parts is labor intensive, and is therefore very time consuming, and also greatly limits design possibilities. Additionally, problems during final assembly may extend overall assembly time, increasing the possibility of moisture adsorption which in turn increases the risk of transformer test failure from partial discharges. Even after the transformer has passed factory tests, if the electrical field is not distributed properly due to the overall design of the lead exits, electrical and/or thermal stresses can increase during operation leading to partial discharges and/or overheating of the unit, therefore further increasing the risk of early failure.

7 PUCARO's new generation of winding lead exit systems, HaPusystem

PUCARO in Germany, another affiliate company of ABB, has recently introduced HaPusystem, a new generation of lead exit systems ➔ 7. This new generation provides greater flexibility during the design and assembly phase of the transformer, and also considerably limits the risk of failure during testing and later in operation.

The unique structure of HaPusystem components leads to more efficient cooling, better distribution of electric stresses and a significant reduction of clearance distances. With such a system, the footprint of transformers can be reduced, while simultaneously minimizing the risk of partial discharges in the lead exit. Due to innovative solutions and materials, HaPusystem lead exit barriers are produced on automatic winding machines, which allow great flexibility in the lead exit design (up to five bends) without significantly impacting its cost. It in turn provides much more flexibility in the transformer design. The HaPusystem standard solution with turret can be installed using a fork lift instead of an overhead crane, making its assembly much faster and more accurate.

The HaPusystem solution for bushing connections is also adjustable. The bushing end shield can be inclined in all directions up to 3° to compensate tolerances. Once the bushing and bushing shield are adjusted, the bushing shield position is bolted. After factory tests, the bushing is dismounted and the transformer transported on site. The bushing shield will however stay in a pre-adjusted position and the bushing can thereafter be installed without any additional adjustments. The assembly time in the workshop and more specifically on site can therefore be reduced by up to 70 percent. Reduced assembly time means limited ingress of moisture, lower risk of failure and overall cost savings for transformer manufacturers.

Stephane Page

ABB Power Products, Transformers

Geneva, Switzerland

[email protected]

Bengt-Olof Stenestam

ABB Power Products, Transformers

Ludvika, Sweden

[email protected]

Carlo Carollo

COMEM S.p.A.

Montebello Vicentino, Italy

[email protected]

Zoran Zic

ABB Power Products, Transformers

Zurich, Switzerland

[email protected]

Anders Holmberg

ABB Power Products, Transformers

Piteå, Sweden

[email protected]

Mladen Banovic

ABB Power Products, Transformers

Zagreb, Croatia

[email protected]