Transmission lines are long-lived assets, with minimum design lives of 40 years; often, these assets are in use for much longer than that. A life of 40-60 years is an eternity compared to the rate at which other aspects of society and technology change. This begs the question: how can today’s utility engineer design transmission lines that can be expected to accommodate an uncertain future?

Forecasting transmission loading decades into the future can be more of an art than a science. In the last two decades, the overall demand for electricity in the United States has been relatively flat thanks to developments in energy efficiency. However, loads are being redistributed throughout transmission and distribution systems due to an increase in distributed generation and the development of concentrated pockets of electrical load from data centers. There is no reason to believe that this load shifting will not continue over the next two decades, for the aforementioned reasons and because of future unexpected changes.

To reduce the risk associated with future uncertainty, utilities are deploying advanced conductors, like Southwire Company, LLC’s C7® Overhead Conductor, for new line designs. This conductor uses a highly reliable, stranded carbon fiber composite core which has a very low coefficient of thermal expansion (CTE) compared to steel cores used in traditional conductors like ACSR and ACSS. The low CTE ensures that there is very little increase in sag as increased electrical loads drive the conductor operating temperature from near ambient to its maximum continuous rating of 180°C.

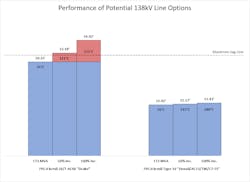

As an example, consider a new 138kV transmission line that is being designed for a maximum continuous rating of 173 MVA. Assume that the new line is located within the NESC Medium loading district and will have 800 ft ruling spans. If the load forecast was perfect, meaning there was no uncertainty, 795.0 kcmil 26/7 ACSR “Drake” would be an appropriate conductor selection. Drake yields 20.25 ft of sag at the maximum continuous operating temperature of 75°C (corresponding to 173 MVA), and 21.66 ft of sag at the emergency operating temperature of 100°C (237 MVA).

Assume now that 20 years later, new generating assets, new load demand, changes to the transmission system architecture, contingency planning requirements, or some combination of all of these factors has led to the need to increase the load on this transmission line by 50-100%. With a steady state load increase of 50%, the Drake ACSR would have to be operated at 113°C, with two additional feet of thermal sag. With a 100% load increase, the Drake ACSR would have to be operated at 175°C, with an increase in sag of five feet over the baseline. Both scenarios would require a reconductoring or reconstruction of the transmission line since ACSR cannot be operated continuously at those temperatures. Additionally, the large sag increase would be unacceptable given minimum clearance requirements.

Had the transmission line engineer identified the risk that load could change substantially during the lifetime of the line, an advanced conductor like Southwire’s C7 overhead conductor could have been used to avoid future cost. In the scenario outlined above, 795.0 kcmil Type 16 “Denali/ACCS/TW/C7-TS” could have been chosen instead. This conductor would be oversized on the day the line was commissioned, operating at around 75°C with 11.02 feet of sag. Under the hypothetical 50% load increase, operating temperature would increase to 115°C with a sag increase of only two inches; the 100% load increase would yield an operating temperature of 180°C with only five inches of additional sag over the baseline. In both of these cases, the choice of C7 overhead conductors during the line design prevented the need for reconductoring down the road as the load profile changed, which could result in a cost savings of up to 95%.

Sponsored by: