Major changes are running through the power industry: On top of industry-mandated indices like the system average interruption duration index (SAIDI) and system average interruption frequency index (SAIFI), many states are introducing a range of other grid efficiency regulations. Further, the energy generator and consumer landscape is becoming more mixed and more sophisticated with intermittent generators like solar and wind sources jostling for grid access and major new consumers, like data centers, placing stringent demands on power providers.

All this is happening to an infrastructure that has changed little since its inception in the early 1900s. This situation has led to the genesis of the so-called smart grid. At the power distribution level, the smart grid offers an intelligent way to approach grid efficiency and reliability, and provides a solid foundation for the automation, and remote monitoring and control of switching. But smart distribution needs smart products, at both the primary and secondary substation levels.

ABB UniGear

Digital ABB's UniGear Digital is not just the next version of an established product. Rather, it is a new concept – a new way of going about MV switchgear. The concept combines well-proven switchgear design with an innovative approach to protection, control, measurement and digital communication. It is based on an optimized integration of current and voltage sensors into MV switchgear, combined with the latest intelligent electronic devices (IEDs) and IEC 61850 communication. The concept is embodied in the UniGear ZS1, an ABB MV air-insulated switchgear (AIS) for primary substations. This switchgear is produced locally around the world and more than 200,000 UniGear panels have already been installed in more than 100 countries. The UniGear ZS1 is used in demanding locations such as offshore platforms, container or cruise ships and mines, as well as in the more common applications, like utility substations, power plants, chemical plants, etc.

Lower cost and easier setup

With the UniGear Digital concept, "one size fits all," so there is no need to change primary MV components, for example, instrument transformers, if the load changes. This saves time and money during project planning and execution.

Energy losses during operation are lower with the UniGear Digital than with equivalent devices: Instrument transformer losses are eliminated and this can save around 250 MWh over the 30-year life of a typical substation. This represents a reduction of about 150t of CO2 emissions. Costs are also reduced because the UniGear Digital has fewer live parts, so outages are less frequent and troubleshooting effort is reduced. UniGear Digital takes up less space in the substation – a real cost-saver where real estate is expensive or limited.

Setup is easier too. The streamlined setup procedure eliminates the necessity, in many cases, to define details such as relay parameters, current transformer (CT) data and voltage transformer (VT) data. CT/VT data does not have to be calculated, checked and approved, and last-minute changes can be realized in the IED logic. IEDs are perfectly suited to protection, control, measurement and supervision duties concerning utility and industrial power distribution – including radial, looped and meshed networks.

Using the IEC 61850 standard, the international standard for electrical system automation, further simplifies things. Protection and control IEDs publish signals for interlocking, blocking and tripping between panels via horizontal GOOSE communication. GOOSE (generic object-oriented substation events) – defined under the IEC 61850 standard – is a control model mechanism in which any format of data (status, value) is grouped into a data set and transmitted. GOOSE communication is becoming popular in substations as it offers simplicity, functionality, flexibility, easy scalability, improved diagnostics and faster performance.

The IEC 61850-9-2 LE process bus is also used by IEDs for transmitting sampled measured values (SMVs). UniGear Digital uses it for sharing busbar voltages, for example.

Secondary substation automation products

Two elements are essential to enable the smart grid at the secondary substation level: automation of the secondary substation switchgear itself and the ability to communicate with the remote SCADA (supervisory control and data acquisition) system. ABB has products that address these: gas-insulated SafeRing and SafePlus ring main units (RMUs) and UniSec air-insulated switchgear.

SafeRing and SafePlus RMU gas-insulated switchgear (GIS) is designed with flexibility and compactness in mind ➔ 1. Each consists of a completely sealed system with a stainless steel tank containing all the live parts.

This virtually maintenance-free system ensures a high level of reliability and personnel safety. UniSec AIS is based on a highly flexible, modular concept that can be readily configured to meet the specific needs of each application ➔ 2.

UniSec is used in secondary substations where normal environmental conditions prevail, no severe space restrictions apply and complex configurations and accessories – with, for example, MV instrument transformers or surge arresters – are required.

Secondary substation automation

To enable automation, MV switchgear is equipped with an advanced grid automation (GA) controller. This device collects data available within the substation, puts it into a standard communication protocol and transfers it to the remote control center for evaluation ➔ 3. This improved level of automation and communication in substations gives the remote operator the ability to adjust different operations in order to:

- Provide high-quality power at all times

- Reduce energy transport losses

- Enhance network stability

- Avoid (or shorten) outages

- Avoid overloading network components

- Improve maintenance planning

- Enhance field crew efficiency

- Optimize asset management

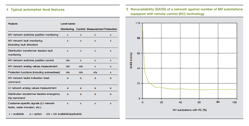

Different levels of remote automation are available for ABB secondary switchgear and the user can select the one that best suits his needs ➔ 4. Each level comes with a predefined IED standard package, which, in some cases, can even be integrated into the MV switchgear, thus eliminating the need for additional mounting space. Customization of these standard packages is also possible. All standard packages include:

- Power supply backup source for IEDs (24 V DC batteries)

- Wired and/or wireless (GSM/GPRS) communication interfaces

- Preconfigured IEC 60870-5-104 remote protocol signals

All IEDs installed within the switchgear or kiosk are factory preconfigured based on the standard package specification. The communication system details (IP addresses, access point name, SIM card PIN, etc.) and MV network parameters (fault pickup current, fault current pickup time, etc.) are usually configured on-site.

GA effectiveness

For a quick evaluation of the effectiveness of a particular GA solution, ABB uses an activity-based costing (ABC) calculation tool developed in cooperation with the National Technical University in Aachen, Germany. This allows calculation of, for example, the impact of a SafeRing installation and standard GA package on SAIDI ➔ 5.

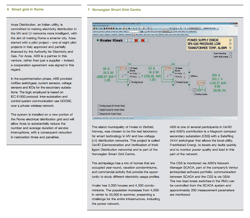

Smart switchgear is already making a big impression ➔ 6–7. The smart grid is still in its infancy. Renewable sources, distributed generation and an increasingly complex and demanding network of power consumers are just some of the factors that will drive future product development in smart distribution switchgear.

This article was previously published in ABB Review Special Report Medium-voltage Products, 2014, pages 11–15.

Vincenzo Balzano

ABB Power Products

Dalmine, Italy

[email protected]

Martin Celko

ABB Power Products, Medium Voltage Products

Brno, Czech Republic

[email protected]