Electric distribution systems long have been held back from many forms of grid modernization achievements because of a lack of operational awareness in the form of accurate, precise overhead-circuit voltage and current measurements. Operational programs such as fault location, isolation and supply restoration (FLISR) and voltage/volt-ampere-reactive optimization (VVO) are proven technologies on demonstration projects. However, widespread cost- effective adaptation of these modern grid programs at Orange and Rockland Utilities (O&R), a Consolidated Edison Co. (ConEd), requires ubiquitous, dependable grid sensing with specific accuracy and installation requirements.

In part, this is a result of O&R’s modern grid vision, modeled after a generation plant distributed control system. O&R’s vision for the grid is to have control devices and instrument measurements all feeding data back to a centrally located server that contains logic to orchestrate model-based programs for control of a wide-area, open network of overhead circuits. This control would be augmented by fallback, stand-alone automation in the field, such as fast-acting fault clearing and recloser loop scheme sectionalizing, in place of FLISR during communication failure.

O&R recognizes the traditional method of installing instrument transformers — current transformers (CTs) and potential transformers (PTs) — to measure volts and amps for overhead circuits is not sustainable across the modern distribution grid. This is due to many factors, including finite space at the top of poles, basic impulse level (BIL), accuracy and calibration, and high-energy secondary signal safety concerns.

The inability to add new sensing technologies to existing pole-top equipment also is an issue. An example of this is the need to use a pole-top recloser at the point of distributed energy resource (DER) interconnection to monitor generation voltage and current in supervisory control and data acquisition (SCADA) system. This challenge is highlighted in the New York Joint Utilities’ efforts to identify and specify low-cost monitoring and control options.

First Try

One of O&R’s original 2010 New York State Energy Research and Development Agency (NYSERDA) grant projects demonstrated new sensing technologies integrated into traditional pole-top devices with SCADA connectivity. A secondary objective was to use the same control meter serve double duty as a power-quality (PQ) node. The device selected for the innovative pole-top design was an overhead distribution switched capacitor bank. O&R added three-phase voltage and current line post sensors, and an automation meter programed to replace traditional socket controllers with features such as a neutral current sensor. Selected capacitor controller/PQ meter calculated values, indicators and control functions were sent over the SCADA communications network and visualized in the human machine interface.

The research conducted under the NYSERDA grant proved conceptually the use of sensor technology for monitoring and control. However, the high cost of construction, metering inaccuracy (as roughly estimated by adjacent, up and down stream recloser values) and sensor signal failure rates prohibited wide-spread deployment.

A New Approach

O&R engineers reflected on how they could approach sensor testing and technology development more effectively. With regard to generation plant distributed control systems, sensors are often calibrated and installed in triplicate for long-term accuracy. For example, a natural gas pressure control system might use a two-out-of-three voting logic routine to reject the outlier measured-pressure value actively.

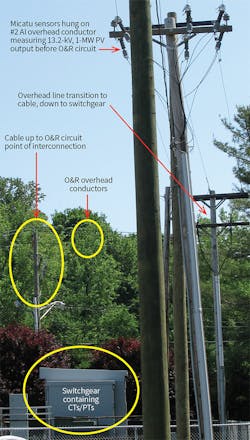

Though this may be too rich for a widespread approach to the modern grid, this concept could be used for a long-term accuracy and precision test bed for evaluating new types of voltage- and current-sensing technologies, instead of the historical install-and-pray approach. O&R found an ideal test location at a recently installed 2-MW solar field that would provide a dynamic electrical source to challenge sensor precision.

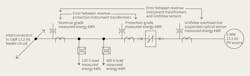

Several spans of overhead 13.2-kV distribution wire over controlled public access land — before the point of interconnection with an O&R overhead circuit — would allow space for a series of sensing systems. This DER also had metal-clad switchgear that houses both protection- and revenue-grade CTs and PTs whose secondary signals had already been tapped remotely by trenched conduit for monitoring purposes.

Project Charter

What attributes did O&R require in the next-generation sensor system?

• The utility needed the ability to install the sensor directly on an overhead line by suspending it from the conductor to overcome the difficulty of pole-top integration. An adaptable sensing technology enabling future pole-top device integration was also a priority.

• A low-energy analog (LEA) sensor, with a 0-VAC to 10-VAC waveform to meter analog input, would provide ease of automation integration and worker safety. Exclusive wireless-sensor data transfer would not meet O&R’s local real-time automation needs, so direct sensor signals would have to be available as PQ meter inputs at the pole automation box.

• Sensors would need imbedded digital calibration for exceptional off-the-shelf accuracy performance. The target was ±1% of full scale. Also, the sensors would need to show proven precision over time at a price that would enable widespread

deployment without an excessive failure rate.

Having selected the desired sensor attributes, O&R considered the relative project tasks from start to finish:

• Identify potential technologies

• Establish commercial agreements with willing vendors

• Perform bench-testing for some technology understanding and performance confirmation

• Install field-ready sensor systems in a long-term field-test facility

• Integrate sensor signals into GPS-aligned PQ meters with a data collection system for 24/7 by-the-minute and event waveform big-data comparison and analysis

• Continually analyze field-test data as an O&R/vendor team; diagnose anomalies; and deploy software, firmware, algorithm updates and refined hardware

• Repeat the process until the desired performance becomes highly probably over a long period.

The final step was to create a multiyear project budget and apply for a ConEd/O&R shared services research and development (R&D) project. Con Edison R&D has administered the O&R-funded sensor project since inception, resulting in several off-shoot projects at Con Edison. These projects use the Micatu sensing technology in unique applications.

Technology Identification

DistribuTECH 2015 was an important show for O&R. The team identified three vendors with sensing technologies in the alpha and beta stages of development. O&R performed bench-testing at two vendor sites; the third vendor could not line suspend its sensor technology.

The bench-testing included a safely staged high-voltage lab area with signal-generating equipment that simulated a high-voltage overhead line. High-accuracy step transformers and isolated low-voltage conductor turns for current were energized and driven by OMICRON software-controlled signal generators. The signal generator successfully excited the 120/7620-V instrument transformer, and a high-accuracy voltage divider was used to confirm the high-voltage transformer output. The Micatu m410 modular optical sensor platform was wired to one Dranetz Technologies PQ meter.

A second PQ meter, with clamp current transducers and low-voltage inputs, was wired in parallel for independent verification of Micatu’s GridView RG235 sensor system measurements. A series of signal generator recipes for voltage as well as current steady-state and transient events were captured in both sets of PQ meters and compared. This lab testing satisfied O&R that a Micatu GridView RG235 sensor system field-testing facility installation would not become an unmanageable burden of troubleshooting and replacement line work.

Only Micatu was suitable for long-term field-testing because of the other vendor’s inability to repeat LEA signals into a local meter. The next step was for linemen to mock install the Micatu GridView RG235 sensor system at O&R’s de-energized pole training yard. Did Micatu have any idea of the three-and-a-half-year journey of product improvement and continued development on which it was about to embark?

To support the tremendous, long-term development efforts, Micatu submitted NYSERDA applications for various program opportunity notices and received grant money to supplement the R&D funding O&R received and its own development investment. NYSERDA recognized the value of this partnership between a New York utility and manufacturer, and the collective support has paid off in a meaningful way.

Long-Term Field-Testing

Micatu’s GridView RG235 sensor system uses fiber-optic light shining through both a magnetic field influenced crystal and a second electric field influenced crystal to measure voltage and current. The integrated light source and receiver are encased in a rectangular metal housing about the size of a dollar bill, which is attached to one end of a 50-ft (15-m) multi-strand, rugged fiber-optic cable that plugs into the pole bottom automation box. The other end is attached to the bottom of the sensor body that is suspended on the bare high-voltage line, which contains the measurement crystals in an insulator body. The physics explanation for this sensing technology is Faraday’s Law and the magnetic permeability tensor of a crystal to rotate the polarized light to measure primary current on a line passing through a hinged iron magnetic focusing core. A separate, different crystal uses the Pockels Effect, also known as the linear electro-optic effect, in which the optical birefringence is proportional to the electric field applied to the detecting crystal. This electro-optic effect is used to directly measure the field strength, which is in proportion to the voltage applied to the sensor suspension clamps, which produces the electrical field at the base of the sensor insulator body. The voltage sensor is shielded at the base of the insulator body, which blocks adjacent fields, and is supported by conductive suspension clamps.

One does not need to have a doctorate in physics to use the Micatu GridView RG235 sensor system and appreciate the sensor performance results. The proof is in the test data. The sensor is supported on the bare line by two compression clamps. When coupled with the sensor bottom ground connection, the 12-lb (5.4-kg) sensor remains firmly in place even in the highest winds, and any conductor size can be used. O&R has tested the sensors on #2 Al wire for years with no visible conductor damage found during inspections. The hinged current clamp is secured around the same wire for current measurement. The end of the fiber cable has a gland seal assembled around the cable after it is passes into the automation box and, finally, slides into a sensor system mainframe socket in the m410. There are no field fiber-optic terminations required because of the factory encasement. The m410 provides a 0-VAC to 10-VAC calibrated and scaled signal for each voltage and current that is wired to the analog inputs of a meter. The m410 is powered by 12 VDC to 24 VDC, and it has more functions and features beyond simply sensing, which O&R intends to test and use over time.

Sensor Benefits and Lessons Learned

As a fiber-optic sensor technology company, Micatu still had quite a development journey ahead once the lab testing was completed. The product metamorphosis that has occurred over the last three years of field-test deployment is significant. The meeting at DistribuTECH and the commercial agreement between O&R and Micatu began paying dividends during the first mock installation with linemen.

The importance of linemen feedback for development of a field-deployable product cannot be overstated; the sensor offering today is quite different from the product used in the first mock installation. Many changes were made, from small items — such as changing to a split copper bolt to attach to the removable ground/shield wire — to far more complex tasks — such as eliminating the need to field prepare any fiber-optic terminations.

By integrating the light source and receiver into a modular rectangular box attached to the fiber end, Micatu made installation less complex. Installation by linemen over the years revealed some important insights. For example, the smallest line sizes require an aluminum compression crimp for the sensor clamps to bite tightly and still be capable of clamping to 500 MCM diameter wire; the balance of the sensor pick point for higher-voltage classes that cannot be gloved was improved; and, most importantly, work practices, methods and devices all were fine-tuned based on linemen feedback.

More to Come

O&R focused on understanding the Micatu sensor product and deciding if it was sufficiently developed to justify the commitment to long-term field testing. The idea is to place the sensor in the field to collect GPS time-aligned voltage and current data (minimum, maximum, average) every minute, to compare to CTs and PTs measuring the same photovoltaic electrical output. However, the testing is performed on an actual overhead line, not in a controlled lab setting. The trick is to place the lab-grade data collection system in the field and connect it to sensors and transformers on live conductors. The test facility materials were purchased, installed and commissioned in the field and the data collection began.

In a follow-up article, O&R will share its field-testing results and lessons learned as well as the tasks completed for production deployment and operational use. ♦

JP Laglenne is a principal automation engineer at Orange and Rockland Utilities with more than 23 years of automation and R&D engineering experience in numerous industries. For the last eight years, he has been focusing on product development and deployment for overhead distribution automation and overhead devices. He is a licensed professional engineer in the state of New York.

Brandon Peifer is an automation engineer at Orange and Rockland Utilities. Peifer develops programs for new distribution equipment and serves as a distribution modeling administrator for distribution planning studies.

Angelo Regan is director of electrical engineering at Orange and Rockland Utilities. He has more than 30 years experience leading the technology transformation occurring at Orange and Rockland Utilities in distribution, substation and transmission. He is a licensed professional engineer in the state of New York and a senior member of IEEE.

Lou Colangelo is distribution SCADA automation engineer at Orange and Rockland Utilities and has more than 15 years of utility experience. He is currently the remote terminal unit and distribution SCADA system subject matter expert, and he has been working on the utility’s advanced distribution management system initiatives. He is a licensed professional engineer in the states of New York and New Jersey.