Like many distribution cooperatives, Minnesota Valley Electric Cooperative (MVEC) continuously strives to provide more reliable service and savings to its members. The cooperative provides electric service to more than 41,000 members across a 968-sq-mile (2507-sq-km) service area, encompassing nine counties. MVEC purchases energy from three wholesale power suppliers — Great River Energy, Basin Electric Power Cooperative and Alliant Energy Corp. — that generate and deliver the electricity to MVEC’s substations. The cooperative is billed for demand and transmission services based on monthly system peaks, which vary from supplier to supplier.

MVEC works to level out peak demand to help control costs, without overcontrolling, which would lead to lost revenue and unnecessarily disrupt members. With existing technology, MVEC already has 44% of its members participating in load management programs, providing an excellent foundation on which to build. However, to build the information technology (IT) and system operations infrastructure needed to realize corporate strategic goals, MVEC needs to implement a single platform for demand-response activities. The utility has selected a demand-response management system (DRMS) to help manage its multiple types of assets and multiple wholesale supplier constraints in one place.

In addition to a DRMS, MVEC also needs to find a way to connect and control commercial assets (generators and photovoltaic sites) as well as field assets (midline voltage regulators and capacitor banks) securely. By gaining the ability to view and control these assets, MVEC hopes to decrease its operational costs to manage assets and increase member satisfaction through better information about their commercial assets. By using these pieces of technology and this approach, MVEC hopes to increase observability, member participation and member satisfaction by controlling devices less often.

In addition to these operational benefits, MVEC also expects to save approximately US$15,000 per megawatt per month, which would translate to big savings over time. For example, if MVEC could cut 10 MW during peak demand times each month, it could achieve savings of $150,000 per month, or $1.8 million per year.

Achievable Objectives

MVEC has spent significant time researching its customers’ asset capabilities and establishing the business drivers behind the desire to control each asset intelligently. With these drivers in place, MVEC can stay focused on framing problems into achievable objectives.

The first foundational objective is to collect data that MVEC’s operations staff can use for better decision making. Before MVEC could begin collecting data, it needed to identify existing data sources such as the geographic information system (GIS), outage management system (OMS), advanced metering infrastructure (AMI), supervisory control and data acquisition (SCADA), customer information system (CIS) and available attributes from these systems. Some examples of available attributes include substation kilowatts, network switch statuses, member notification preferences and member consumption information.

Throughout this process, it became clear to MVEC staff that knowing more about each member’s assets was key to moving forward. Actual observed consumption during similar days of the week with similar weather can be used to determine how much demand response is delivered on a demand-response event day. Additional information from larger, more complex sites with on-site generation can include values from annunciator panels (generator alarms), generator output and fuel levels. These key data points can be used to ensure success when MVEC calls on the assets for picking up the customer’s load and off-loading megawatts from substations across the MVEC system.

Actionable Information

Once the data is identified, it needs to be collected, organized and displayed automatically for the MVEC system operator. To achieve this objective, system-level baselines are created to show how many megawatts can be reduced or transferred over to the customers’ own generation. Similarly, baselines are created to show the expected savings from residential water heating and air conditioning programs. These baselines are presented jointly to the system operator. The operator can see what load control capabilities are available, given the conditions impacting system loading that day.

MVEC made a key decision during this process to use a single platform to pull in data and provide the system operator with a unified way to analyze the situation, notify customers and dispatch control signals to the various systems. This enables the dispatcher to focus on solving the business issue and not have to focus on how to communicate to all the lower-level systems.

Once the system-level data is turned into actionable information, MVEC can concentrate on developing the business rules for the system operator. The business rules come from a variety of sources, including regional transmission organization (RTO) operational rules; multiple generation and transmission (G&T) company rules, incentives and constraints; multiple coincidental and non-coincidental peak management time frames; and MVEC’s own operational practices. It quickly became apparent managing all these business rules in real time would be challenging and take a great deal of knowledge. This presents problems when individuals across multiple shifts are required to call demand-response events, so MVEC began looking for a system that could help to make its vision a reality.

Leveraging Technology

MVEC reached out to Open Access Technology International Inc. (OATI), a software-as-a-service provider to the energy industry, to find a solution that could help the utility to realize its business goals. MVEC uses the OATI webSmartEnergy platform to consolidate information flows and provide a decision-support tool that helps to guide the system operator through the complex set of business rules.

Along with providing multiple baselining methods to estimate how the assets will perform, the solution also has a feature-rich implementation for triggers. This trigger functionality enables the utility to specify complex calculations and if-then logic that can use almost any source data available in the system. MVEC plans to use this triggering functionality to construct complex business rules for the system operator.

MVEC will set up multiple triggers to support maintaining the enhanced DRMS response. Load-level triggers will notify the system operator when the system is reaching or ending DRMS event times. Multiple triggers also can be set up to feather in or feather out the available demand-response assets to help maintain the monthly demand target during the event. A key concept is to control a target safely below the financial target (165 MW), but also to not overcontrol it, which may cause customers to issue complaints or the utility to lose revenue needlessly.

Current Challenges

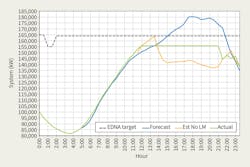

The two graphs represent some of the current challenges MVEC faces. The first graph shows MVEC’s system load over a five-day period and identifies the observed metered load. The red circles show when MVEC’s wholesale suppliers (G&Ts) bill their demand charges.

One G&T assesses its demand charges on what would have been the G&T’s monthly peak, the red circle on the left, while the other supplier bills MVEC based on the cooperative’s highest observed load during the month, which in this chart occurs the morning after the load control event from the night before. Managing these individual peaks and the constraints placed on MVEC by members, the G&T’s and eventually the Midcontinent Independent System Operator (MISO) is complex and requires a supervisory system.

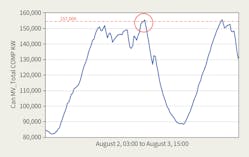

The second graph shows the importance of controlling rebound peaks immediately after a load control event. On the day with the red circle, a rebound peak is set when restoration of commercial and industrial loads, interruptible water heaters and air conditioners were restored from load control as well as allowed to begin using grid energy again.

This in-rush consumption needs to be managed to realize the benefits of controlling load in the first place. Otherwise, the value of the load control programs is significantly eroded. Integrated systems, increased analytics, and the ability to monitor field assets in real time allows MVEC manage rebound peaks with two methods simultaneously. Fracturing the programs allows operators to gradually restore loads over a greater period of time, while ate the same time being able to give participating members accurate times for when they will be called on to participate. MVEC has seven generators in seven control groups while all other programs are divided into four groups. Increased situational awareness allows MVEC operators to better understand the programs’ impact on system load at any given point in time using both real-time and historical data from tens of thousands of endpoints.

Additional Capabilities

Another important aspect of the overall solution is to have tools to analyze how the system performed. The MVEC team needed answers to the following questions:

• From a demand and energy perspective, how effective were the controls?

• Did control failures happen during the day?

• What are the financial impacts of each set of assets?

• What is the cost of the controls versus the savings achieved for the events?

• How did today’s operations compare to previous control days?

The new platform provides the system analyst many tools to answer these questions. Performance reports are available for each demand-response scenario (one or more demand-response programs scheduled to run concurrently) to look at the event on a system level. Additional reports enable the user to drill down into the details to see substation, feeder or customer-specific performance information. All the demand-response scenarios are stored on the system, so it is easy to review or compare performance across different control days.

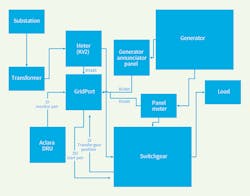

MVEC also is deploying several OATI GridPort devices, enabling the utility to connect end-use devices securely to the distribution grid to give transparency to field assets.

By installing an OATI GridPort and integrating it with the generator’s control module, MVEC can access generator data and turn the generator on and off with either an on-demand or a predefined schedule. This enables MVEC to lessen the load demand on the grid, when needed, by turning on generators during peak demand times to provide power to the owners’ facilities — ensuring additional cost savings and reliability not only for MVEC but also its members.

MVEC is working to leverage this data to provide business owners with more information at their fingertips. Depending on the available data points at the generator, owners would be able to understand the following:

• When their generator responded to load control signals

• What the facility load was at the time

• How much energy was served by the generator

• How much energy was served by MVEC

• When the generator ceased to operate and the facility returned to utility power

• Whether a generator is available for control, based on status, alarm or fuel-level data points

Deploying technology that provides its operators with more information will give MVEC a better understanding of the impact its generator program has and enable the utility to provide even more information to business owners on the status of their generators.

The Future

MVEC’s solution will continue to evolve as new sensor equipment is installed in the field and as its business rules evolve. Following are some examples of ongoing activities MVEC has planned:

• Rolling out additional OATI GridPort devices to most of the remaining 100 generators, as the technical and economic indicators predict reasonable returns

• Tuning of event triggers to more closely reflect MVEC’s business objectives and the information needs of the system operator

• Deploying additional OATI GridPort devices connected to midline voltage controllers and capacitor banks to provide additional observability and control

• Setting up rates and incentives for the cooperative to have observability and control capabilities to include photovoltaic inverters as controllable devices into a more advanced DERMS solution

• Preparing to offer incentives and controls that match MVEC’s business objectives and help to minimize the customer’s ongoing costs as electric vehicle car chargers take off.

Through the enhanced use of its distributed assets, MVEC hopes to achieve its business objectives while minimizing the impact to the comfort and productivity of its member-ship. As it looks to the future, the cooperative will continue to invest in technology that helps the cooperative to provide more reliable services and savings to members just as it has done for the past 85 years. ♦

Eddie Webster III currently serves as director, demand response and program development for Minnesota Valley Electric Cooperative in Jordan, Minnesota, U.S. Prior to joining MVEC, Webster was the demand-response and emerging technologies lead for Great River Energy, one of MVEC’s power suppliers. He has more than a decade of experience creating and managing demand-response programs, both for utilities and commercial customers. Webster has led many efforts to achieve more efficient and valuable demand-response operations, and he has a keen understanding of the potential demand response holds at the various operational levels, spanning distribution operations through the organized wholesale power markets.

Check out the September 2017 issue for more articles, news and commentary.