Utilities face a significant challenge in prioritizing investments across myriad transmission, substation and distribution equipment to make most effective use of limited capital and operating budgets. Traditionally, Commonwealth Edison (ComEd), a unit of Exelon Corp., has relied on asset health and project risk scoring frameworks to facilitate this prioritization. These are quantitative methods designed to target the worst performing assets and most impactful projects across the system. These methods have produced notable improvements in reliability, environmental and safety performance.

However, ComEd is now benefiting from the growing population of remotely monitored and controlled grid devices, primarily as a result of advanced metering infrastructure and distribution automation installations. To extract the full value from these investments, ComEd is in the process of designing a platform to leverage this growing volume of data. The platform — Business Intelligence and Data Analytics (BIDA) — will be designed in collaboration with Baltimore Gas and Electric Co. and PECO (ComEd’s sister utilities) and promises to serve both as the foundation for data storage and access across the enterprise, and to provide the processing tools needed to perform advanced analytics. This will translate to more precise asset health assessments and more targeted asset investment planning.

Asset Management

The rapid U.S. grid expansion in the 1950s and 1960s was followed by a period of decelerated development due to low demand growth. The 1980s and 1990s saw limited investment in system maintenance across the industry, with work being biased toward “extent of condition” type programs (that is, addressing populations of a given asset known to be prone to failure).

These programs took a limited view of asset health and failed to recognize variations among equipment that may have developed over time. While these programs are still appropriate for some assets, reaching to the next layer of asset risks requires a more granular understanding of asset conditions.

In 2007, ComEd began revamping its approach to asset management with the introduction of health indices and risk scores. Health indices assess the condition of individual assets rather than targeting equipment by age or model. Assets with poor health scores are reviewed with the appropriate engineering team and projects are developed to address the identified issues. These projects are then assigned risk scores to provide a measure of criticality that can be used for prioritizing work across the service territory. These asset health and project risk scoring frameworks have continued to evolve as ComEd incorporates its lessons learned over time into these analyses.

Currently, ComEd calculates health indices on a quarterly basis for major transmission and substation equipment. These are based on several equipment-specific factors. For example, the factors for oil circuit breakers include maintenance history, age, power factor test results, oil test results, timing performance, resistance and loading. Each piece of equipment is rated against appropriate factors, followed by weighting and aggregating of the factor ratings, to obtain the final health index, which is fit to a scale from 0 to 100.

For assets with poor or very poor scores (<50), projects are developed to address the condition issues. For transmission and substation equipment, the data needed to perform this analysis is compiled from various systems including supervisory control and data acquisition, PI Historian, Asset Suite, Cascade and additional homegrown databases.

Distribution equipment requires a modified approach to the health index framework. This is because of the significantly larger asset population and lower asset replacement cost for distribution equipment as compared to substation and transmission equipment. For these reasons, the health of these assets is more appropriately assessed using reliability metrics. Metrics such as system average interruption frequency index (SAIFI), customer average interruption duration index (CAIDI), and customers experiencing multiple interruptions (CEMI) are measured at the feeder level to identify worst performing circuits for further engineering analysis and preventive and/or corrective maintenance investment.

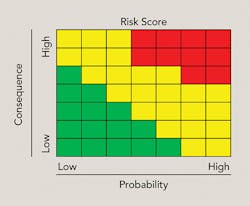

For all ComEd electric system investments (distribution, transmission and substation), the annual business planning process creates projects or programs of work to address ComEd’s lower-performing asset population as identified through the asset health process. Once projects and programs are developed, they are assigned a single risk score based on probability and consequence of risks mitigated by the investment. This risk score is calculated using ComEd’s risk model and ultimately allows work to be compared on a common platform, regardless of work type or voltage class.

Leveraging Data

ComEd’s investment in analytics will leverage data from smart meters and distribution automation to identify asset risks more precisely. Several analytics use cases are now being pursued and many more are expected to be identified as analytics develop and additional sensing devices are deployed.

ComEd is designing the platforms and analytical tools needed to integrate real-time data streams into static data sets for transmission and substation equipment to enable a more robust asset health scoring system. This system is expected to provide several advantages over the current, purely static view:

•Equipment health indices will be updated in real time while taking into account system configurations.

•The system will be able to send automated notifications to spur timely preventive or emergency maintenance.

•Engineers and asset managers will be provided with more detailed and timely data to update their asset management strategy.

Data from the installed smart meters and distribution automation devices also will provide unprecedented visibility into distribution system conditions. Initially, this data will be used to develop health indices for entire circuits — similar to the current practice for transmission system equipment evaluation — by aggregating smart meter data to the distribution transformer level and assessing the loading as well as voltage conditions for each transformer on a circuit. These data points can then serve as one of many factors in the health index calculation for that specific circuit. The circuit ranking tool becomes more robust as additional factors are identified that will further direct engineering analysis to reduce asset risk systematically.

In addition to supporting circuit ranking, this data can be used directly to address abnormal conditions proactively on an individual asset basis. For instance, ensuring equipment is not overloaded can increase life expectancy and enable optimal use of distribution assets. Similarly, overvoltage and undervoltage conditions can be identified and managed to improve the quality of service as well as reduce equipment wear.

Failure Prediction

Analysis is underway to identify patterns and relationships to support predictive capabilities. Preliminary studies have identified a specific voltage profile that may be related to transformer failure. Although too early to declare statistical significance, several cases have been identified where aggregated smart meter data show voltage spikes followed by sustained overvoltage conditions roughly one month to three months before transformer failure.

By studying this relationship, predictive models could soon support proactive replacement of transformers linked to this voltage profile. Similarly, short-duration undervoltage conditions have been found to precede sustained tree-related outages. Detecting this pattern automatically would enable more timely and targeted vegetation management and reduce outage frequency.

As analytics improve, the signatures of specific equipment failure modes could be differentiated. A fast-leaking transformer might be differentiated from that of a slowly deteriorating one, thus allowing crews to be dispatched first to the more critical risk, and accordingly mitigating environmental damage and preventing a future outage. These examples are a few of the many identified use cases being analyzed, with many more still to be conceived.

Phasor Measurement Units

In line with deploying grid-sensing technologies and data analytics, ComEd is exploring the potential for phasor measurement units (PMUs) to provide visibility down to the alternating-current cycle level. The utility has been involved in the deployment of synchrophasor technology on its transmission system through participation in a PJM Interconnection-led project. Progressing to a more granular application of these devices, PMUs could be deployed on distribution feeders to monitor the operations and condition of nearby devices precisely. It is possible measurements of open and close operation timing for reclosers and automatic switches could trigger alarms when sluggish operations are detected.

PMUs also may detect abnormal operating patterns such as an excessive capacitor switch or recloser operations. This information could point to a feeder problem or control malfunction that could be addressed proactively.

Building the Platform

The development of a robust BIDA platform is being recognized within the Exelon Utilities family as a key strategic initiative that will enable ComEd and its sister utilities to reap further benefits of their smart grid investments. As ComEd progresses toward data-driven asset management, each of the applications being considered clearly depend on the ability to access timely and vast sets of data, and to manipulate them into actionable intelligence using constantly evolving analytical tools.

The BIDA platform is being carefully designed both to serve as the enterprisewide system for universal data storage and access as well as to provide the processing tools needed to support advanced analytics. Flexibility and scalability are core requirements being built into all aspects of this system to accommodate the data streams.

To structure the near-term design, sourcing and deployment of this system, uses cases and system requirements are currently being evaluated and prioritized within five functional domains: advanced metering infrastructure, transmission and distribution grid infrastructure, smart energy services, customer experience and business support.

The transmission and distribution grid infrastructure domain focuses heavily on improving analytics related to asset health and investment planning, which are core components of strategic asset management.

Final Thoughts

With so many aspects of daily life dependent on the presumption of reliable electric service, the critical task of managing the nation’s aging transmission and distribution infrastructure must continue to evolve to ensure resources are applied precisely when and where they are needed most. ComEd has come a long way in advancing its asset management strategy over the past decade. The introduction of health indices and risk scores nine years ago delivered a step-change improvement in the utility’s ability to direct investments strategically to address asset risks.

With the passage of the Energy Infrastructure Modernization Act in 2011, the system was propelled forward in terms of overall infrastructure condition, and smart grid technologies were deployed broadly across the service territory. Looking forward, ComEd plans to raise the bar for asset management by leveraging the unprecedented level of visibility into system conditions that is afforded by the smart grid. This is an exciting time for innovative and analytical minds to collaborate in driving the next evolution in asset management.

Patrick Graves is a senior project manager in ComEd’s smart grid and technology group. In this role, he focuses on developing service offerings around innovative smart grid technologies and supports Exelon’s efforts to strengthen its data analytics capabilities. Graves previously served as a project management office consultant for large-scale infrastructure modernization programs, managed energy-efficiency programs for a leading energy service company, and developed power market forecasts and asset valuation models.

Shay Bahramirad is an IEEE senior member and the director of smart grid and technology at ComEd, where she serves as a strategic business leader supporting the transformation to the 21st century power grid and the new energy economy. She is leading the smart grid organization across ComEd to develop the vision, business models and investment strategy of the grid for future initiatives such as emerging technologies, microgrids and smart cities.

Joe Svachula is vice president of engineering and smart grid at ComEd, where he is responsible for the utility’s engineering planning and reliability programs as well as developing and implementing operation plans for the installation of ComEd’s smart grid projects and other related technologies. He is a senior member of IEEE and former co-chair of the 2014 IEEE Power & Energy Society T&D Exposition.

The Energy Infrastructure Modernization Act

The passage of the Energy Infrastructure Modernization Act (EIMA) by the Illinois General Assembly in 2011 marked a significant advancement in ComEd’s asset management programs, especially with respect to the distribution system. EIMA enabled ComEd to launch a systemwide portfolio of investments to replace aging infrastructure and to modernize the grid. The investments significantly accelerated the proactive replacement of distribution assets and further allowed for the deployment of technologies that support better distribution asset condition visibility.

The five-year EIMA infrastructure programs primarily address replacing and rejuvenating aging distribution assets. The criteria for inclusion of specific projects or equipment in these programs vary from one program to the next, but generally include reliability history or inspection findings. An example of this is the underground rural distribution “Assess, Treat, Replace” program, where fused half-loop circuit candidates are selected based on the number of fuse operations experienced over the past two years as a result of cable faults. For the worst performing circuits, if cable rejuvenation is feasible, cable injection work is performed to fill voids in the cable insulation and to protect against future cable faults. Cables that cannot be injected are replaced.

Another objective of the EIMA programs is deployment of new smart grid technologies. This mainly includes the replacement of all ComEd’s retail electric meters with smart meters as well as expansion of distribution automation (DA), among other programs. Through the DA program, S&C Electric and G&W Electric sectionalizing devices with remote communications capabilities are strategically installed on 12-kV and 34-kV distribution feeders to detect issues and automatically reroute power to minimize customer impact. The modernization programs also include the development of 10 intelligent substations over five years through the upgrade of relays and monitoring and control systems.

This accelerated investment portfolio has reduced ComEd’s system average interruption frequency index from 1.54 interruptions per year in 2011 to 0.88 interruptions per year in 2015. In fact, 2013, 2014 and 2015 have been the three best years of reliability in ComEd’s history. Now a unique opportunity has emerged to improve asset management practices.