Urbanization is one of the most important global trends. It is expected migration from rural areas will result in two-thirds of the world population residing in cities by 2050. As a result, demand for electric power in cities continues to increase. This presents utilities with a major challenge.

Faced with the problem of increasing demands and lack of environmentally acceptable sites for additional extra-high-voltage/high-voltage outdoor substations in city centers, utilities must consider alternative solutions in the form of indoor substations. Land use sometimes dictates the installation of new substations in basements within existing buildings. But this oil-immersed electrical plant has risks in the form of fire and explosions. And, since SF6 is a greenhouse gas, its application to insulate equipment is not desirable.

Distribution substations equipped with dry-type transformers have been installed in buildings for many years. Until recently, dry-type transformers were only available for voltages up to 36 kV. The relatively new development of dry-type transformer technology with the manufacture of units designed for subtransmission voltages now offers a cost-effective alternative solution for supplying city center loads. Apart from eliminating the need for expensive fire and explosion protection, the subtransmission circuits offer increased load-transfer capacity and reduced system losses.

Dry-Type Transformers

Dry-type transformers do not use any inflammable liquids for insulation or cooling, so their main advantage compared with liquid-immersed transformers is safety. This makes them the preferred choice for underground or city-building substations that require site-specific fire prevention and fire contingency-management strategies. For many responsible authorities, the potential risk of oil-immersed transformers to humans and assets is still considered too great, and the related costs of protection measures are not economically justified.

In 2013, the International Council on Large Electric Systems (CIGRE) published a “Guide for Transformer Fire Safety Practices” for power transformers rated above 10 MVA with voltage levels up to and including 66 kV. A survey on transformer failures concluded some 10% of all transformer failures result in a fire. Annually, about one out of 1,000 power transformers catches fire.

Dry-type transformers use air as the main insulation medium. The dielectric strength of air is considerably less than oil, so dry-type transformers are larger and more expensive. The dielectric stress within the dry-type transformer is taken up by solid and air insulation. As a result of the higher permittivity of the solid insulation, the electric field is reduced. Therefore, the main insulation comes from air.

One possible drawback of dry-type transformers is the higher iron loss in comparison with the oil-immersed transformers because of the need for larger dielectric clearances, which results in a larger core.

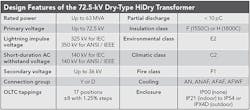

Currently, there are no International Electrotechnical Commission (IEC) or IEEE standards for subtransmission dry-type transformers, but manufacturing standards for the higher-voltage units were selected to fulfill the same requirements for partial discharge as the existing IEC standard specifies for transformers up to 36 kV, namely a maximum level of 10 pC at 1.3 Un. This standard guarantees there will be no degradation of the insulation as a result of partial discharge, thereby ensuring the operational life of the transformer will not be compromised.

New Dry-Type Equipment

In response to customer demands, ABB — following research and development work and intensive testing — has developed and manufactured 72.5-kV dry-type HiDry72 transformers for subtransmission applications. For transmission and subtransmission applications, on-load tap changers (OLTCs) are a prerequisite.

The 72.5-kV dry-type transformers are available with vacuum-cast coil or RESIBLOC coil technology. The vacuum-cast coil technology uses foil disc windings together with epoxy resin and silica filler casting technology. The RESIBLOC transformers are cast resin reinforced by glass fiber filament. This reinforcement offers superior mechanical strength, making them most suitable in the event of extraordinary load cycles, short-circuit currents or other mechanical strain.

The OLTC is based on dry-type, oil-free technology of linear switching type. The linear configuration is used for dry-type OLTCs at lower voltages and is well proven. Vacuum interrupters are used as diverter switches. The OLTC consists of a separate unit for each phase, and offers 17 positions and a tapping range of ±10% with a maximum voltage step of 900 V. The OLTC is designed for 100,000 operations between maintenance intervals.

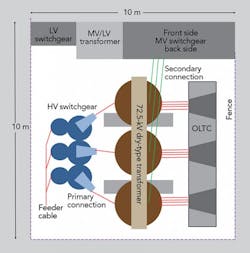

Combining dry-type transformers with gas-insulated or hybrid gas-insulated switchgear results in a very compact and safe indoor substation suitable for installation in the basement of any building.

Brazil Project

The oldest and third-largest city in Brazil, Salvador da Bahia, was chosen to be one of the cities hosting the 2014 FIFA World Cup. The new Fonte Nova Arena with a 55,000-seat capacity is supplied by 69-kV underground cables. The local utility, Coelba, part of the Neoenergia Group, established a high-voltage/medium-voltage substation, which was integrated into the stadium.

The substation has two 69-kV, 25-MVA dry-type transformers, each equipped with vacuum-interrupter-based OLTCs having a tapping range from +4% to -12% in 1.25% steps. The transformers and OLTCs are both installed without an enclosure. The incoming 69-kV feeders are connected to the dry-type transformers by a simple bus bar system.

This substation allows spectators to sit above the substation. Apart from satisfying all the safety considerations, the reduced need for civil works resulted in significant cost savings.

Sweden Project

Ulricehamn Energi, the local utility in Ulricehamn, a city close to Gȅteborg in Sweden, had to replace an oil-immersed transformer in an outdoor substation located in an environmentally sensitive and forested area. To satisfy environmental and other issues, the utility installed a 45/11-kV, 16-MVA transformer equipped with an OLTC with voltage steps ±75 in 1.67% steps. The transformer is designed with RESIBLOC coils to withstand Sweden’s very low temperature conditions.

An IPX4D transformer enclosure was installed at this outdoor substation to protect the unit from water ingress and possible intruder vandalism. The enclosure was designed to allow ventilation for cooling the transformer by natural convection. The transformer is connected by cables entering and leaving at the base of the transformer; hence, the enclosure does not require bushings. The transformer was delivered on-site in the enclosure with the OLTC mounted on the transformer.

Canary Island Project

Spanish transmission system operator Red Eléctrica de España (REE) is undertaking a smart grid demonstration project using a flywheel for energy storage. The project is on the Canary Island of Lanzarote at a 66-kV substation in the municipality of Tias. The energy storage device is supporting the frequency and voltage stability in the Lanzarote-Fuerteventura grid.

The 66-kV/440-V, 1,800-kVA dry-type transformer was delivered on-site fully assembled with the enclosure, including wall bushings for the high-voltage supply. This feature together with the fact the substation is located in an area at risk for forest fires were the main reasons REE opted to install dry-type transformer technology.

Plan Madrid Project

The Villaverde substation is part of the plan Madrid project developed by Spanish utility Iberdrola in agreement with the regional government and the city of Madrid. The plan replaces extra-high-voltage and high-voltage transmission lines crossing Madrid with an underground cable network. There will be 16 air-insulated substations dismantled and 18 new indoor substations built.

The Villaverde indoor substation is an important node in the Madrid transmission system. It is equipped with 220/132/45-kV voltage levels with the following configuration:

- 220-kV double-bus bar, 63-kA gas-insulated substation (GIS) with 15 line bays, two transformer bays, two coupling bays and two bus bar break bays

- 132-kV double-bus bar GIS with two line bays and one transformer bay

- 45-kV double-bus bar with SF6 switchgear with seven line bays, two transformer bays and two auxiliary services bays

- One 220/132-kV, 225-MVA autotransformer

- One 220/45-kV, 100-MVA transformer

- Two 45-kV/420-V, 250-kVA ABB HiDry72 transformers for auxiliary services.

The two dry-type transformers have replaced two oil-immersed transformers of similar ratings, which supply auxiliary services protected by 45-kV fuses. Hence, Iberdrola has improved safety within the substation by eliminating a potential fire hazard. The replacement dry-type transformers are simply screened by a fence to prevent unintentional contact with the energized transformer.

Cordoba Project

The electrical equipment at an industrial plant in Cordoba needed to be refurbished. The plant has its own substation supplied by a 66-kV underground cable. The substation is equipped with two 66/20-kV, 12-MVA dry-type transformers with OLTC; two 66-kV GIS; 10 primary megavolt switchgear (ZX0.2) with two 20/5-kV, 8.5 MVA dry-type transformers; and six secondary megavolt switchgear with six 20/0.4-kV, 800-kVA dry-type transformers. The 8.5-MVA transformers supply a test laboratory, and the 800-kVA transformers supply different parts of the factory and compressors. There are additional feeders for an external third-party supply. The whole substation is integrated into the factory buildings.

The 66-kV dry-type transformer already exceeds the new eco-design requirements of the European Union. The regulation requests a minimum peak efficiency index of 99.36%.

Sevilla Project

The picturesque and well-known city of Sevilla in the south of Spain accommodates several 66-kV substations, which supply a population of 700,000. Two substations, located in special substation buildings in the city center, were completely refurbished in 2014-2015. The local utility replaced the existing oil-filled power transformers with air-insulated transformers to eliminate any related risk for the neighborhood. Each substation has two transformers.

The 66/22-kV transformers have a power rating of 31.5 MVA and a winding configuration of YNyn0. They are each equipped with an OLTC providing ±1.25% in eight steps. The transformers can be operated for up to 90% load under natural convection; in case of higher load, fans placed at the bottom of the coils support the cooling. The dimensions of each transformer is 6 m (20 ft) in length with a height of 5 m (16 ft) including all accessories. The transformers, which are not enclosed, are fenced.

One of the 31.5-MVA transformers with OTLC mounted was short-circuit tested at the CESI independent laboratories in Italy, in accordance with the relevant requirements of IEC 60076-5.

Going Forward

The development of dry-type transformers for subtransmission applications in the last few years is a major step forward with respect to providing equipment with increased safety for people, property and the environment. The first installations of the 72.5-kV dry-type transformers in operation have already proven excellent performance. As the risk of a fire or explosion is practically nonexistent, dry-type transformers are the ideal choice for indoor and outdoor installations.

Indoor substations installations can be made especially compact if GIS or hybrid switchgear is used together with dry-type transformers. Expensive space in buildings can be minimized and underground substations in city centers can be designed for increased capacity, reducing subtransmission system losses. For example, in a compact indoor substation with a transformer capacity in the range of 10 MVA to 40 MVA, the required footprint is 10 m by 10 m (33 ft by 33 ft) with a room height of 7 m (23 ft). Therefore, it is expected more compact and standardized designs for indoor substations will become available in the coming years.

About the Author

Gerry George

Gerry is a chartered electrical engineer and a member of the Institution of Electrical Engineers. Gerry’s background includes extensive time and experience in engineering and managerial positions in the UK Supply Industry. As part of the T&D World editorial team, Gerry works with contributing authors around the world and represents the magazine at major transmission and distribution conferences and exhibitions in Europe.