Modern substation automation systems rely on a variety of microprocessor-based equipment that requires numerous settings and configuration files. Configuring and archiving of substation device configurations such as protection relays, programmable logic controllers, intelligent meters and human-machine interface (HMI) require significant time and effort.

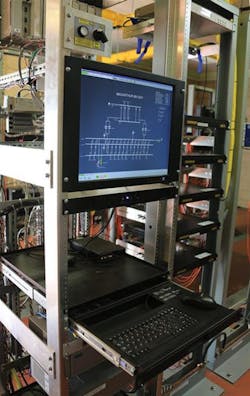

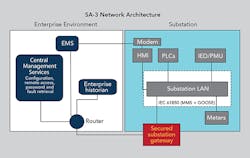

As part of its smart grid demonstration in Irvine, California, U.S., Southern California Edison (SCE) is piloting SA-3, a new substation automation system based on the IEC 61850 standard. The pilot includes a configuration management application, which consists of a data-driven process that can predictably generate, track and centrally archive changes to configuration files in real time. Configuration management is one of eight applications in the SA-3 pilot.

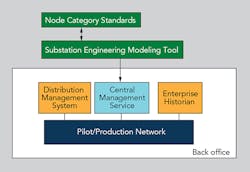

The configuration management application, installed at SCE’s MacArthur substation in Newport Beach, California, is composed of three major components:

- Substation engineering modeling tool (SEMT)

- Centralized management services

- Substation gateway.

SEMT Configuration

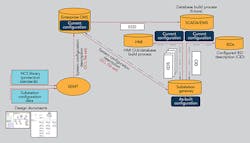

SCE’s in-house SEMT serves as an IEC 61850 system configurator, capable of methodically generating all the files required to configure substation devices, including intelligent electronic devices (IEDs), managed switches, the substation gateway and the HMI. SCE originally developed SEMT for consistent generation of an HMI point list for communications to the utility’s energy management system (EMS) and expanded its capabilities for this application. The SEMT also generates reports such as point lists and test scripts used for automated testing.

To generate the required relay configuration files for factory acceptance testing, SEMT uses SCE’s node category standards (NCS), which standardize and catalog the application-specific settings for each type of relay. NCS are organized and maintained to contain the settings and associated documentation, and can include both machine-readable and human-readable material.

The SEMT configuration process begins when a user manually configures substation information from design drawings. Based on the user-configured data, the SEMT determines which template from the NCS library is to be applied to each supported IED. In this fashion, the SEMT creates the standards-based system configuration language (SCL) file set that drives the SA-3 configuration process while maintaining point list generation support for SCE’s legacy substation automation systems.

The SEMT-generated SCL file set consists of a combination of IEC 61850 standard file extensions such as the system configuration description (SCD) file and SCE-defined standard-compliant extensions that are the basis of the data-driven configuration process.

Centralized Management Services

The IEC 61850 SCL file set is used to automatically configure the appropriate management services with substation-specific data such as substation name, managed devices listed by model and type, communications information, and associated power system information such as source and feeders that correspond to equipment. Additions and modifications to devices in existing substations can be made during the configuration process.

The Centralized Management Service (CMS) implements role-based access controls. This provides additional security to the system. Groups are configured by role — such as substation test technicians, protection engineers, protection leads and read-only users — with permissions to edit, approve or view only, depending on the user’s role.

The SCL file set and its individual components are version-controlled by the CMS. A fully configured substation in the CMS enables authorized users to update individual components through a check-in/check-out process of individual configured IED description (CID) files and update the SCL file set for configuration of end devices. These capabilities enable end users such as protection engineers to provide and approve updates to protection settings and have them immediately available for a test technician to deploy in the substation.

Substation Gateway

Once the new substation configuration files are at the substation gateway, the technician is responsible for uploading the new configurations to the devices. When an authorized user is ready to initialize or update a configuration, the user at the substation initiates the transfer of the SCL file set from the CMS to the substation gateway. When receiving an SCL file set, the substation gateway can configure itself with substation-specific data if no existing configuration exists. Alternatively, the substation gateway can generate a visual display of configuration differences between the running configuration and the new configuration if the gateway has existing in-service configuration data. This gives the user an opportunity to review and accept or reject the changes to the substation gateway.

The substation gateway also has two operational modes. The first of these is used when the gateway is unattended and prevents any configuration changes from being initiated, either locally or remotely from the CMS. The second operation mode enables a user to initiate and make configuration changes as needed.

Configuration of end devices is achieved from the substation gateway. A configured substation gateway provides a list of supported devices whose configuration can be sent to the device by an authorized user. Although the configurations in the substation gateway are in the form of IEC 61850 CID files, CID files are not yet the de-facto standard for IED configurations.

To overcome this challenge, SCE developed a composite CID file. This is a standard IEC 61850 CID file with vendor-specific files embedded in private data fields. In this manner, the IED configuration files can be managed as CID files. The substation gateway is able to separate the vendor-specific configuration files from the CID, and configure the IEDs using a variety of communications protocols and mechanisms supported by the end devices.

The substation HMI was developed with the capability of accepting the entire SCL file set from the substation gateway as its configuration. Once received and accepted by an authorized user, the HMI would build its database and graphical user interface automatically without additional user interaction. The enterprise historian includes an IEC 61850 client that can be configured using IEC 61850 SCL files. Upon user initiation, the substation gateway sends the SCL files via manufacturing message specification (MMS) file transfer to the historian for automatic data point population and connectivity to the substation.

The version management capabilities are extended to the substation gateway. When changes to a device configuration are detected, whether authorized or unauthorized, the substation gateway detects and provides the CMS with the latest configuration at the substation. This allows the CMS to be in sync with the in-service configurations at the substation.

For the CMS to contain the latest configuration for devices, it is necessary for the substation gateway to monitor devices continuously for changes to configurations. This poses a challenge since existing devices do not support a uniform way of reporting or monitoring configuration changes. Custom solutions for different device types were developed using several methods, such as polling specific registers for configuration information, simple network management protocol traps and IEC 61850 logical nodes. Once a change to a device configuration is detected, the gateway downloads the device configuration in its native format and repackages the file into a composite CID file. The file is then transferred to the CMS for version management and archival.

Evaluation and Feedback

The substation automation project has been deployed in the field, but data is still preliminary at the time of this writing. Data collection will be carried out until the end of 2015. The following is to serve as feedback to utilities and vendors in the area of configuration management.

This new system has the ability to monitor and update configuration to a limited number of devices because of the lack of consistent methods for monitoring, retrieving and updating device configurations; therefore, custom solutions had to be developed for each type of device. The lack of a standard way to update configurations may require new methods to be developed every time a new device type is added to the system and, in some cases, might require full cooperation from the device manufacturer. The preferred solution would be for a device to be able to accept one complete CID file — with settings (including logic) and all 61850-related information — to the device through MMS. Change detection also should be possible through logical node data attributes and reporting. A common method would have made system development and integration more efficient.

Network connectivity from the enterprise environment to the substation is required in order to take full advantage of the benefits of this configuration management solution. Utilities considering a similar automation system should establish key requirements such as NERC CIP compliance and determine which existing systems will be affected. Technical requirements should be aligned with operational and organization needs prior to commissioning in order to avoid operational inefficiencies. For example, responsible parties should have a plan for system events such as unexpected configuration change detections.

Next Steps

SCE’s SA-3 pilot demonstrated the viability of a data-driven configuration management process using various device types made by various manufacturers. Once this pilot is concluded, successful features will be considered for inclusion in new production systems after lessons learned have been applied. The next phase of the SA-3 project will include applying configuration management features to legacy electronic devices.

Mehrdad Vahabi ([email protected]) has been part of the automation/communications group within the advanced technology department at Southern California Edison since 2011. He was project manager for next-generation substation automation system and the human machine interface project. He has more than 11 years of experience in engineering, research, design, sales and project management, as well as national and international experience in substation automation, SCADA, energy management system and distribution management system projects.

Zeus Xioco ([email protected]) is a senior engineer at Southern California Edison with 12 years of automation experience. He is currently lead engineer for the substation automation group within SCE’s advanced technology department. He is tasked with identifying and piloting the next-generation substation automation technologies that could have significant impact to SCE and the industry. He holds a BS degree from California State University, Los Angeles, and is a California licensed professional engineer.

Jesse Silva ([email protected]) has been a substation automation engineer at Southern California Edison since 2006 and is part of the automation/communications group within the advanced technology department. He was technical lead for the substation gateway project and is also responsible for researching, designing and testing next-generation substation automation systems at SCE. He holds a BS degree from the University of California, Irvine, and is a member of IEEE.