In the early days of breaker technology, conventional distribution breakers were used as GCBs. Then, with larger generators in power plants and increasing output from these generators, the machine ratings exceeded the load currents and short-circuit levels of the switchgear available. Therefore, the "unit connection" (ie, a connection without a circuit breaker between a generator and the associated main transformer) became the accepted standard power plant layout.

BBC, one of the two companies that became ABB in 1988, developed and introduced GCBs with air-blast technology in the 1950s and the first units were installed in power plants in North America and Europe. Nowadays, GCBs are recognized for their many advantages compared with the unit connection, such as simplified operational procedures, improved protection of generator, step-up and unit auxiliary transformer and higher power plant availability.

GCB technology advances

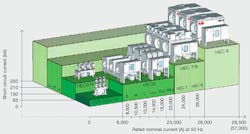

ABB further pioneered the development of circuit breakers that use phase-segregated busducts with higher unit ratings in the 1960s. In the 1980s, ABB successfully introduced SF6 GCBs using a three-phase system in single-phase enclosures. Meanwhile, the life-cycle costs of installed GCBs with air-blast technology became too expensive in terms of service and maintenance costs, therefore ABB continued to develop state-of-the-art SF6 GCB technology throughout the 1990s and phased out air-blast technology. Since then ABB has introduced various new types of GCBs with increased functionality to the market - most recently type HEC 9 with the world's highest short circuit current breaking capability at 250 kA using SF6 technology at a rated maximum voltage of 31.5 kV.

HEC 9's development is an upgrade of the design and development of the GCB type HEC 7/8, which is able to cope with short-circuit currents up to 210 kA and to handle rated currents of 50,000 A or more, where the latter requires forced air-cooling. Increasing demands - mainly from newly developed nuclear power reactors like the Westinghouse AP1000 or Areva's EPR - showed that short-circuit currents above 210 kA combined with generator voltages of up to 30 kV are realistic.

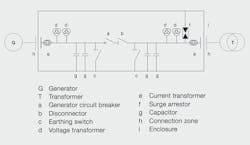

The success story of HEC 7/8 immediately led to the decision to use its design principle in the HEC 9 along with the same functionality, just at a higher energy level. Consequently the total size and mass of the HEC 9, as well as the required operating energy, increased compared with HEC 7/8 ➔ 1.

To limit transport weights and sizes as well as allowing the use of the well proven operating mechanism HMB 8 of HEC 7/8, it was decided to build HEC 9 as a single-pole operated system, ie, the three poles are mounted on individual pole frames together with their own operating mechanisms, which now offered three times more operating energy per pole, compared to the smaller HEC 7/8 ➔ 2.

Using detailed and advanced simulation tools meant it was possible to reduce the number of development tests as well as shortening the development time. Additionally development tests are necessary to avoid unwelcome surprises during the type testing phase. A big effort has been put into a firm measurement technique, withstanding high pressures, temperatures and mechanical shocks.

Another big effort has been to carry out temperature rise tests where the maximum temperature of the equipment is measured at various positions under different normal current ratings and different cooling conditions. In the ABB High Current Laboratory normal currents of up to 50 kA for both 50 and 60 Hz can be run.

All of the necessary type tests have been carried out exceeding today's standard requirements for GCBs. For example, the generator source short-circuit current up to 200 kA with a high degree of asymmetry of more than 120 percent, and additional tests showing higher dielectric or mechanical limits.

Air-blast compared with SF6 technology

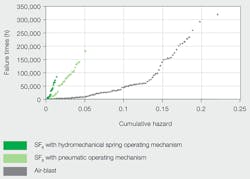

SF6 GCBs are much more reliable than air-blast GCBs. The difference between the reliability parameters of air-blast and SF6 GCBs can be mainly attributed to the higher complexity of the former technology and to the aging of its components. Compared with SF6 circuit breakers, much higher pressures are used in air-blast circuit breakers.

Pressurized air has a relatively long time constant to recover to its nonconducting state so special means need to be applied to reduce the rate-of-rise of transient recovery voltage to values the circuit breaker can cope with. A resistor is generally mounted in parallel to the interrupting chamber of air-blast GCBs.

The disadvantage of this solution is that additional interrupting units are required to interrupt the resistor current. These additional interrupting units increase the complexity of the system, lead to additional sources of failure and in turn reduce the overall reliability of the GCB. It is the operating mechanism that is the main source of major failures in high-voltage breakers [1]. The hazard rate of an air- blast GCB is 5.6 times higher when compared with an SF6 GCB with a hydromechanical spring operating mechanism. Air-blast GCBs are equipped with a pneumatic operating mechanism. In this respect, the pneumatic drive has a failure rate 2.6 times higher than a state-of-the-art hydromechanical spring-drive-equipped ABB GCB [2] ➔ 3.

The mechanical endurance of an air-blast GCB is also much shorter than that of an SF6 GCB, which leads to a lower maintenance frequency, lower operating costs, and also to a higher availability of the SF6 GCB.

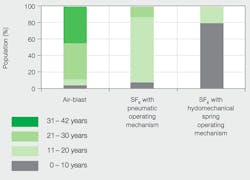

Furthermore air-blast is an obsolete technology that has several disadvantages compared with SF6 GCBs. For example higher noise levels, longer opening times, longer-lasting downtime due to maintenance operations and lower availability of spare parts. In the surveyed population the vast majority of air-blast GCBs are older than 20 years. The average age of the population of air-blast GCBs is 29.4 years; in other words, 1.7 and 4.3 times older than that of SF6 GCBs with pneumatic operating mechanisms and hydromechanical spring drives, respectively ➔ 4.

Reliable and safe power generation

ABB GCBs are suitable for application in all kinds of new power plants such as thermal, gas turbine, nuclear combined cycle, hydro and pumped storage power plants, as well as for replacement or retrofit in existing power stations when they are modernized and/or extended ➔ 5 - 6.

As a market leader in GCBs, ABB has a global installed base of more than 7,000 units. ABB GCBs are produced in Europe's 2010 Best Factory Award winning plant, which is in Switzerland, using an advanced flow production system that can assemble and test a breaker in only 2 days versus 2 to 3 weeks using the previous production system.

6 Success story: VC SummerVC Summer is a nuclear power plant owned by SCANA. The plant is just outside Columbia, South Carolina, United States. Originally commissioned in 1984, the plant has a net capacity of 966 MW. Legacy DR air-blast GCBs were part of the original construction to protect the turbine generator. The core issue ABB's GCB service team in Princeton, New Jersey, United States, provided a swift solution by utilizing their customer network. The same model legacy breaker was relocated from another plant. Using parts from the other site and the Swiss ABB factory, ABB's service crew was on-site to get the unit back in service. However it was recognized that the solution was a "band-aid" and concerns about reliability remained. The customer's engineering task force team had to weigh their options and figure out a proactive and, most importantly, safe solution. From six options - including the risky choice of eliminating the GCB altogether - VC Summer decided it was time to make an investment in the dependable and easy-to-maintain ABB HEC-7 GCB. Hatching a plan When the breaker arrived, the team discovered that it could not fit through the delivery hatch. Due to a modular design and the availability of the ABB team, some removable components were removed to make clearance and then replaced. The breaker was fully commissioned and closed by May 2011. During a presentation at ABB's customer event, Automation and Power World 2012, the customer stated: "Extensive on-site testing by ABB gave us full confidence in the breaker. To date, the breaker has been at load with no issues." Operation and maintenance personnel can have peace of mind knowing the exact status of the new breaker thanks to the GMS 600 monitoring system paired with HEC-7. The state-of-the-art device allows communication directly with the plant monitoring system to give full visibility of the status. A full spare phase module and drive mechanisms further ensure that the plant can optimize availability. In addition, ABB has factory trained and certified personnel to perform the aftermarket field services required to keep the equipment operating properly and safely. |

Protecting the world's largest power plants

ABB leveraged more than 10 years of calculations and testing with the HEC 7/8 to produce the HEC 9. It has a compact design and offers an integrated system solution that provides a 20 year service interval that gives the end user a low lifecycle cost with maximum system availability ➔ 7.

HEC 7/8 as well as HEC 9 are used in the most prestigious power plants of any kind in the world such as in the largest thermal power units rated from 600 to 1,000 MW, hydropower units from 650 MW and above and nuclear power units up to 1,800 MW.

Giosafat Cavaliere

Rüdiger Kreisel

ABB Power Products, High Voltage Products

Zurich, Switzerland

[email protected]

[email protected]

--------------

References

[1] "Final Report of the 2004-2007 International Enquiry on Reliability of High Voltage Equipment. Part 2 - Reliability of High Voltage SF6 Circuit Breakers"

[2] M. Palazzo, et al, "Reliability Analysis of Generator Circuit-Breakers, CIGRE Session 2012."