ABB was formed in 1988 by the merger of two European power industry giants: ASEA from Sweden, and BBC from Switzerland. The history of these two giants dates back to the 1800s, and fortunately each of these pioneering companies established factories and sales offices in many corners of the world, an adventurous legacy, which has helped lay the foundations for much of ABB's current success.

At the core of this strategy was the goal to be close to markets and customers served, which is why ABB's high-voltage products business is present in more than 100 countries. While the overriding technologies may be similar, different regions and countries are continually demanding specific developments and applications, so being close to individual markets helps ABB to better understand and translate customer needs into appropriate products, solutions and services.

Innovation at ABB is not solely about providing groundbreaking technology, but actually applies to many aspects of the company's broad portfolio, business model and people – this is a clear differentiator in today's very competitive marketplace.

Driving competitiveness on the supply side

ABB's high-voltage products business alone is supported by about 40 factories spread across many countries throughout North and South America, western and eastern Europe, Asia and Australia. This global footprint enables ABB to leverage manufacturing volumes and supply chain sourcing around the world, while a growing number of local assembly units ensures customers receive maximum value, including engineering, installation and commissioning support.

ABB's generator circuit breaker (GCB) factory in Zurich, Switzerland was voted European Factory of the Year in 2010 (Die Beste Fabrik 2010) at the "Best Factory Conference" organized by the German business journal, Wirtschaftswoche. The selection jury included industry specialists and academics from leading international business schools, including INSEAD and WHU-Otto Beisheim School of Management.

The ability to maximize efficiency and productivity were among the main evaluation criteria. The jury appreciated the factory's layout, ergonomically designed workstations and state-of-the-art logistics systems. The modernized and streamlined production processes increase both productivity and manufacturing capacity. Relative to the old production site, space in the new facility was reduced by half, production capacity doubled and delivery time cut from weeks to days.

ABB continues to make investments that optimize this footprint and expand its global reach ➔ 1 – 2; for example, the company is currently building new facilities in Saudi Arabia and India that are designed to meet local customer demands and needs. Another clear example is our approach and flexibility in sourcing. Subject to customer preference and approval, ABB can leverage its global footprint and offer alternate factory production. This is advantageous to both the customer and ABB, as it provides the flexibility to reduce lead times and increase speed-to-market as per customer requirements.

|

2 R&D – Investing for tomorrow ABB' global R&D organization consists of about 8,000 scientists spread around the world in seven research centers located in the United States, Switzerland, Sweden, China, India, Germany and Poland. These labs collaborate with about 70 universities globally on an extensive range of subjects. The company's in-house, high-power laboratories are equipped with the latest state-of-the-art facilities. To keep up the constant stream of new products and technologies ABB globally invests over $1.3 billion in R&D annually. In the high-voltage products business, the stream of recent innovations includes new gas-insulated switchgear (GIS) concepts; a high-voltage circuit breaker with an alternative insulating gas for enhanced eco-efficiency; ultrahigh-voltage technologies for 1,100 kV ultrahigh-voltage direct current (UHVDC) and 1,200 kV alternating-current (AC) transmissions; generator circuit breakers (GCBs) for the world’s largest power plant units, rated up to 1,800 megawatts (MW); and sulfur hexafluoride (SF6) cryogenic recycling technology. These are only a few of the outstanding technologies that clearly signal the innovation focus of ABB's high-voltage products business. |

ABB's field service organization is another very important part of the company's business offering, one where a local presence is fundamental. ABB's High Voltage Products business unit currently employs more than 1,000 experts around the world in 26 service centers that are geographically positioned to rapidly respond to any current or future life-cycle service requirement.

The high-voltage power market is changing, a fact which ABB has recognized early, adapting its portfolio and skill base accordingly. More and more customers require some form of remote monitoring, and this capability is not only changing ABB's resource needs, but those of its customers. The ability to remotely monitor substation assets for all critical diagnostic metrics to assure increased reliability is now available.

3 ABB's mobile service container

Another focus area is to provide the most advanced methods to minimize the end-of-life environmental impact of all original equipment manufacturer (OEM) assets. These services provide the end customer with the confidence and security that asset disposal truly will have minimal impact. Another recent development is ABB's mobile service container, which drastically reduces outage time in environmentally harsh and remote locations. HV breaker repair and refurbishment in harsh weather conditions like snow, rain, or sandstorms can make working on-site nearly impossible, and can also impact the integrity of a repair. Yet transporting the unit to a service facility is also usually impractical. Under these conditions, another solution is the mobile service container ➔ 3, a 40-foot container suitable for land and sea freight that is fully equipped with all the necessary tools to service, repair and refurbish ABB's HV circuit breakers. The service container is widely used in northern Europe, and has also been deployed to China and Azerbaijan.

Building domain competence through close customer contact

ABB's high-voltage products business serves many markets, channels and applications. Span of supply can vary from a single product or spare part to a complete, integrated high-voltage substation or solution. A clear strength of ABB is its ability to offer customers complete and comprehensive products, systems and service portfolios.

At the same time, ABB can also provide customized solutions and responses to specific requests – such as reducing substation footprints and creating special substation configurations – utilizing innovative, flexible products. Another ABB initiative is the establishment of regional power quality centers in markets close to customers; these centers offer solutions to improve power quality and energy efficiency in power networks. The centers specifically focus on ABB's capacitors and filters product line, which is a vast portfolio of products that provide an optimal application range based on local requirements. Power quality centers can help find the best technical solution for every need. They solidify ABB's technical expertise in a region, and enable the company to develop a reliable service partner network. They also help to fine-tune ABB's product portfolio by providing valuable market feedback to product development and design centers. ABB has established seven power quality centers so far, covering North America, South America, Europe, the Middle East and Africa, South Asia, India, and China.

ABB sales and marketing teams play a key role by remaining close to ABB customers. Growing and developing local organizations and people is the fastest way to enter local markets and establish sustainable customer relationships. A key focus for ABB involves taking the appropriate time and making the investment to ensure competent, customer- facing organizations that support and develop local markets.

Listening to customers is one thing, but it is also essential to invest the time to understand them and their businesses. Beyond pure business interactions, ABB generally proactively invests substantial resources in order to understand what customers in all global markets really think, to better understand and even anticipate their needs. This process marks what ABB does well, but also identifies from a customer perspective what must be improved. Internally known as the Net Promoter Score (NPS), the results are shared openly throughout the business, and help to drive improvements across functions and business areas. Having surveyed more than 15,000 customers in 2012, initial analysis indicates customers like ABB's technical support, industry and applications knowledge and partnering for mutual benefit. On the whole, customers appreciate ABB's domain competence, but the same survey also indicates they would like to see improvements in some areas, such as on-time delivery and lead times. As a result of the NPS survey, these areas are the focus of increased management attention to improve customer responsiveness.

Staying abreast of global trends

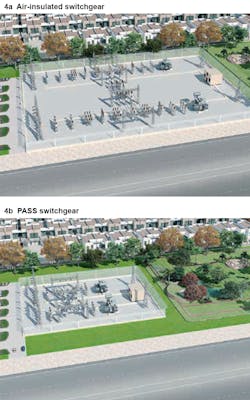

In a rapidly urbanizing world, space is at a premium, and in response the footprint of ABB's high-voltage switchgear has become smaller and smaller. For example, ABB's hybrid high-voltage switchgear modules can reduce switchgear bay space requirements by 60 percent, compared with conventional air-insulated switchgear technology ➔ 4.

4 Comparison of the space requirement of air-insulated and PASS switchgear in an H5 substation configuration

Another rapidly growing need is for renewable energy products. As offshore wind generation advances toward higher- capacity turbines with ratings of 5 MW and more, losses that occur during energy transfer will escalate unless higher voltages are used. This is leading to an increasing number of applications for high-voltage equipment in the wind energy market. ABB meets this demand with the new and compact high-voltage, multifunctional switchgear module PASS M00, which can be inserted and fitted in the narrow spaces of a wind tower ➔ 5.

5 ABB's 72.5 kV PASS in a windmill

To facilitate quick access to the electric grid with minimum work on site, ABB has made several of its high-voltage products available as plug-and-play solutions. This eliminates on-site assembly work, as products are factory sealed under controlled conditions, which helps to reduce commissioning time and ensure superior and consistent product quality.

The future belongs to smart grids. In order for a grid to become smart, it must first be able to access and integrate the real-time status of its numerous components. ABB's intelligent switchgear solutions provide digital output according to international standards and facilitate remote data monitoring and control.

Another significant trend in high-voltage markets is ultrahigh-voltage bulk power transmission over long distances, with minimal losses and low environmental impact. ABB's latest technology advancements in these areas are highlighted in this special edition of ABB Review.

A famous proverb says change is the only constant, and that is ABB's guiding principal. By constantly evolving with customers and markets, ABB can better understand current and future needs and provide maximum value. This effort is spread across all functions of ABB's business, from R&D, manufacturing and supply chain management to marketing, service and skills development.

Richard Oulton

ABB Power Products, High Voltage Products

Zurich, Switzerland

[email protected]

--------------------------------------

ABB Review Special Report High-voltage products March 2013

Editorial Council

Prith Banerjee

Chief Technology Officer and Executive Vice President

Georg Schett

Head of Technology Power Products division

Fredi Stucki

Technology Manager High Voltage business unit

Richard Oulton

Marketing and Sales Manager High Voltage business unit

Harmeet Bawa

Head of Communications Power Products and Power Systems divisions

Namita Asnani

Communications Manager High Voltage business unit

Rona Victoria Gregorio

Project Coordinator PG GIS/GCB, High Voltage business unit

Andreas Moglestue

Chief Editor, ABB Review

Publisher

ABB Review is published by ABB Group R&D and Technology.

ABB Technology Ltd.

ABB Review

Affolternstrasse 44

CH-8050 Zurich

Switzerland

[email protected]

ABB Review is published four times a year in English, French, German, Spanish and Chinese. ABB Review is free of charge to those with an interest in ABB's technology and objectives. For a subscription, please contact your nearest ABB representative or subscribe online at www.abb.com/abbreview

Partial reprints or reproductions are permitted subject to full acknowledgement. Complete reprints require the publisher's written consent.

Publisher and copyright ©2013

ABB Technology Ltd.

Zurich/Switzerland

Printer

Vorarlberger Verlagsanstalt GmbH

AT-6850 Dornbirn/Austria

Layout

DAVILLA AG

Zurich/Switzerland

Disclaimer

The information contained herein reflects the views of the authors and is for informational purposes only. Readers should not act upon the information contained herein without seeking professional advice. We make publications available with the understanding that the authors are not rendering technical or other professional advice or opinions on specific facts or matters and assume no liability whatsoever in connection with their use. The companies of the ABB Group do not make any warranty or guarantee, or promise, expressed or implied, concerning the content or accuracy of the views expressed herein.

ISSN: 1013-3119