One technology that is used extensively in the electrical industry for dielectric insulation and current interruption in circuit breakers, switchgear and other high-voltage equipment is the inert gas known as sulfur hexafluoride (SF6) ➔ 1. It is used in applications in the magnesium and semiconductor industry, and also has some uses in military applications.

|

1 SF6 gas SF6 is a man-made gas and is one of the six greenhouse gases listed in the Kyoto Protocol.* Today SF6 accounts for only about 0.1 percent of mankind’s contribution to the greenhouse effect even though it has a global warming potential that is 22,800 [1] times greater than carbon dioxide. SF6 facts:

---------------- Footnote ---------------- Reference |

ABB mainly uses SF6 in high-voltage electrical equipment. The gas has excellent insulating and arc-quenching properties, enabling the design of more compact equipment. Land use, energy consumption, losses and waste are all considerably reduced, while the ability to recycle is enhanced.

ABB goes to great length to ensure that SF6 gas is not allowed to escape into the atmosphere when equipment is manufactured, erected, serviced or scrapped and that any hazardous and decomposed products are disposed of in a compliant and environmentally responsible manner. The company is continually researching viable alternatives, seeking to reduce the amount of SF6 used in its products.

High-voltage CO2 breaker

One promising alternative to SF6 is to use carbon dioxide (CO2) as the insulating and arc-extinguishing medium. ABB's high-voltage live tank breaker LTA 72D1 is the first high-voltage circuit breaker to use CO2 in this way ➔ 2.

2 Success story: ABB's LTA CO2 DCB proves itself on the European grid

One of the largest generators of electricity and the largest generator of heat in Europe, Vattenfall is a pioneer in developing and adopting new technologies that facilitate the production of energy in an environmentally sustainable manner. ABB's LTA CO2 disconnecting circuit breaker (DCB) takes Vattenfall a step closer to its goal.

The DCB is a concept pioneered by ABB in the year 2000. By integrating the disconnecting function within the breaker, the DCB does away with the need for separate disconnectors and increases equipment reliability and availability. It also improves the eco-efficiency of equipment throughout the life cycle by using fewer primary apparatus and consequently, fewer raw materials. DCBs also create lower electrical losses during the use phase due to lower electrothermal losses. Last but not least, they can reduce the physical footprint by as much as 60 percent.

The LTA CO2 concept breaker was installed in a pilot project at a 132/45 kV substation in Sweden in 2010, and has performed faultlessly since then. Operated by Vattenfall, the substation comprises six 132 kV and nine 45 kV bays.

The LTA CO2 DCB, which is positioned as a busbar circuit breaker, performs a dual role, functioning as a capacitor bank circuit breaker for part of the year and as a line circuit breaker for the remaining period. In a year, the equipment performs almost 400 breaking operations.

While the LTA 72D1 is designed for a rating of 72.5 kV, its outstanding performance at 145 kV confirms that it has the potential to support far higher voltage levels of CO2 technology.

The LTA 72D1 circuit breaker is currently available for 72.5 kV distribution networks with short-circuit breaking current requirements up to 31.5 kA. It is available as a conventional circuit breaker as well as a disconnecting circuit breaker (DCB).

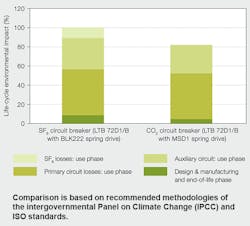

The evaluation of the LTA circuit breaker's environmental impact of over its life cycle has been made with regard to global warming potential (GWP). GWP is the value that describes the contribution of a substance to global warming over its lifetime. The result is expressed in CO2 equivalent emissions over the product’s life cycle. The graph in ➔ 3 compares the life-cycle environmental impact of ABB's LTA CO2 circuit breaker with ABB's LTB SF6 circuit breaker over a service life of 30 years. As per estimations based on recommended methodologies of the Intergovernmental Panel on Climate Change, by replacing SF6 with CO2, CO2-equivalent emissions can be reduced by about 10 tons or 18 percent over a 30-year lifetime.

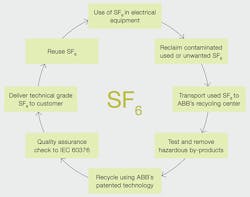

Yet another method of reducing the environmental footprint and increasing grid eco-efficiency is SF6 recycling ➔ 4. ABB recently launched a patented technology for the comprehensive recycling of contaminated SF6 gas, based on an energy efficient cryogenic process. The purity of recycled SF6 gas using the newly developed technology is more than 99.9 percent and is in accordance with technical grade IEC 60376 (the standard for new gas), which enables SF6 to be reused again and again. Using recycled SF6 gas helps reduce carbon emissions and has a cost savings potential of up to 30 percent. The greatest technical advantage of the new process relative to earlier technologies is that it can efficiently recycle SF6 irrespective of the type or level of contamination. The older technologies suffer from an inability to treat all contaminants and all contamination levels in one process. Furthermore, the level of automation in the new process allows significantly greater throughput.

Online monitoring of SF6 gas with the CBS line of products

Minimizing gas leaks is also of great concern when it comes to SF6. Online monitoring of equipment using SF6 gas enables continuous supervision and thus faster dispatch for any SF6 gas leak repair. ABB's Circuit Breaker Sentinel™ line of condition monitors includes a compact electronics and sensor package to determine temperature-compensated pressure in single-compartment SF6-insulated switchgear – the CBS-F6. The Windows-based software enables remote online monitoring and continuous trending of deviations from the required pressure ➔ 5.

Fiber optic current sensors

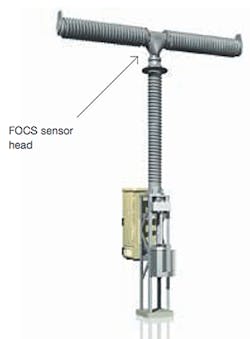

In recent years, current and voltage sensors have started to replace regular oil-insulated instrument transformers in smart switchgear applications. For high-voltage air-insulated substations a fiber optic current sensor (FOCS) is a smart alternative to traditional current transformers. FOCS offers a "plug and play" solution and, with its digital interface, is designed for IEC 61850 communication. The sensors improve eco-efficiency by eliminating oil or SF6 as insulation media, thereby removing the risk of oil spills or gas leakages. FOCS also eliminates the need to use tons of material, such as aluminum, copper cables, steel and concrete foundations, and substantially reduces the substation footprint. ABB's FOCS is integrated with live tank circuit breakers, including disconnecting circuit breakers ➔ 6.

Dry cable terminations

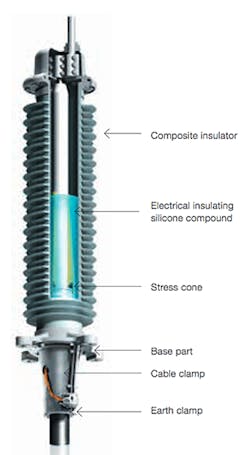

ABB's dry self-supporting cable termination comes preassembled and prefilled with an electric insulating elastomeric silicone compound from the factory ➔ 7. This prefabrication means there is no risk of incorrect handling or risk of oil or chemical leakage during transportation or at site. Dry solutions have the added advantage that, in the event of a failure, they are less likely to cause damage to surrounding equipment and, more importantly, are less likely to cause personal injury.

Addressing the life cycle

In each phase of a product's life cycle there are environmental implications such as power losses and waste production. ABB adheres to ISO standards to measure and assess the environmental impact of its products throughout all phases of the products' life cycle. Broadly speaking, these phases are: manufacturing, use and end-of-life. For high-voltage products a life cycle is usually between 30 and 40 years. ABB leverages its 100+ years of experience in high-voltage technology to continually improve product design and as a result reduce environmental impact in all phases of the life cycle.

Manufacturing phase

In this phase ABB's objective is to reduce the embodied energy in its products. Embodied energy is the sum of all the energy required to produce goods or services. Over the years ABB's products have become lighter, which means they use less material per kV and kA of power transmitted. In addition, the volume of SF6 gas used in ABB's products is decreasing. For example, from 1995 to 2012 the SF6 gas volume in a 420 kV AIS CB has dropped by 20 percent, and from 2006 to 2012 the SF6 gas volume in a 420 kV GIS bay has fallen by 40 percent. As a general practice, ABB always aims to use the most energy efficient processes in the manufacturing phase.

Use phase

Due to the long life cycle of high-voltage products – generally between 30 and 40 years – as well as other factors (eg, operational energy use), the use phase usually accounts for 70 to 80 percent of the total environmental impact. For example, circuit breakers use energy in their drive mechanisms. ABB uses compact spring drive mechanisms that require low energy, replacing bulky hydraulic drives that consume far more energy over their life cycle. Additionally, as current flows in the conducting parts of the equipment, there are some associated electrothermal losses. ABB's special designs and materials ensure low resistive losses. Insulating mediums used in high-voltage products such as SF6 gas and oil will, if leaked, negatively impact the surrounding environment. ABB thus ensures SF6 gas leakage rates consistently below 0.5 percent by using special well-proven sealing systems for indoor and outdoor applications, down to – 55 °C.

The end-of-life phase

In addition to employing the latest recycling technologies, ABB makes use of easily recyclable and disposable material in its products to the greatest extent possible. Proper documentation with clear declarations also reinforces improved recycling and disposal.

Improving the eco-efficiency of ABB's products and solutions is a continuous journey and encompasses conducting research and development to discover breakthrough technologies as well as continuously evaluating and lowering the environmental impact of existing products and solutions.

Namita Asnani

ABB Power Products, High Voltage Products

Faridabad, India

[email protected]

Fredi Stucki

ABB Power Products, High Voltage Products

Zurich, Switzerland

[email protected]

----------------------

Further reading

- www.iso.org

- B. Alexander et al., "SF6 and a world first: ABB launches the first-ever SF6 recycling center," ABB Review 1/2012, pp. 22-;25.