Control of industrial boilers has to be kept tight to squeeze the most out of these assets. ABB's Fingerprint analysis helps do this.

Oil prices are a good indicator of general energy costs. From 1989 to 2003, the average price of a barrel of oil was around $20, rising to $50 by 2005 and peaking at nearly $150 in mid-2008. Apart from the financial planning headaches such volatility causes, the eye-watering energy bills landing on companies' doormats bite deeply into profitability. For energy-intensive equipment like industrial boilers, the challenge is particularly acute: A 150 klb steam/hr (68,040 kg steam/ hour) industrial boiler running on natural gas would have had an annual fuel bill of around $ 5 million between 1989 and 2002, rising to $10 million in 2007 and to $20 million in 2008. Where the future trend is heading remains is unclear.

One place to look for cost relief is in the hardware and software dedicated to optimizing boiler operation. Having this in good working order brings many benefits:

- Energy savings

- Better response to process steam demands Extended operating range for the boiler

- More reliability

- Improved safety

- Reduced carbon footprint

Loop gain

Like much industrial equipment, steamproducing boilers rely on PID controllers to regulate the process, reduce product instability and improve operations. However, ABB is finding that in PID automation:

- PID loops are not being maintained

- PID loops have degraded

- PID loops are hampering production and performance

- Associated equipment is not performing properly

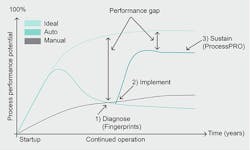

1 Optimization service methodology

Because of this, ABB has introduced a Fingerprint analysis service that will improve the performance of boilers. The Fingerprint examines the state of hardware and controls, tests the stability and operation of the boiler, performs combustion load trials and executes dynamic step response tests. In the Fingerprint process, boiler operations are first benchmarked to define existing performance levels and establish a basis for identifying and evaluating improvement opportunities. Recommended improvements are scrutinized to estimate return on investment (ROI) and are then prioritized according to payback. Subsequent actions fix the problems and sustain performance ➔ 1.

There are three phases in the analysis:

Diagnose (Fingerprint)

- Measure performance gap

- Forecast ROI

- Deliver action plan

Implement (hands on)

- Fix performance gap

- Define monitor plan

Sustain (scan/track)

- Manage performance gap

- Schedule maintenance

- Define condition triggers

- Maintain to conditions

Back on tune

The Fingerprint that was performed on four small industrial boilers at the Arkema chemical facility at Calvert City, Kentucky, a site that includes the world’s largest HFC-32 refrigerant production plant, provides a good illustration of the power of such an analysis.

The Arkema site has four boilers. These produce steam at slightly different levels because they are different sizes and were installed at different times ➔ 2. The first two boilers, both installed in 1952, are brick-set with forced-draft (FD) intakes and induced- draft (ID) removal fans. Both are rated at 40 klb/hr. The third boiler, a 1965 economizer, has only an FD fan and is rated at 75 klb/hr, though it was typically operated at a maximum of 60 klb/hr.

The fourth boiler, a 1996 economizer, of the flue gas recirculation (FGR) type, was operated identically to the third.

All four boilers produce steam at about 165 psi, but none were run at maximum load. The Fingerprint work began with the second boiler as it is the one used most often and it is the least efficient.

Initial examination revealed that the ID fan positioner movement was jerky, indicating a potentially faulty pneumatic cylinder or piston assembly. The FD fan was also found to have issues ➔ 3.

The ABB team noticed a loose hatch door near the oxygen sensor that was leaking air into the ductwork before the ID fan. Also, the two boiler oxygen sensors continued to read about 2 percent higher than a portable analyzer.

The leakage meant that air was being added for an oil flow that was not truly going into the boiler. Air flow and fuel flow measurements were, thus, going up and down. They were both exhibiting hysteresis, so working against each other and creating variability.

In addition, a furnace draft test indicated leakage air was being sucked in by the ID fan and emitted from the stack as wasted power. Based on load tests, the air/fuel ratio setting was updated. (The oxygen trim that fine tunes the air/fuel ratio had been underused in recent years, leading to suboptimal operation.)

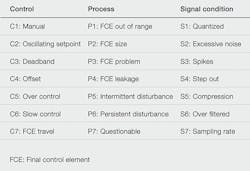

4 Results of control loop monitoring

There is an industry rule-of-thumb that says that, six months after installation, the performance of around 50 percent of process control loops will be degraded to some degree. Accordingly, control loops were monitored using the Loopscan tool and a number of deficiencies found ➔ 4.

The Fingerprint analysis resulted in a comprehensive to-do list. The following improvements were identified for hardware:

- Repair FD and ID control drives

- Resolve oxygen transmitter reading issues: check calibration, find leak, change location

- Adequately seal all doors

- Recalibrate steam flows

- Add blowdown flow monitoring (blowdown removes solids buildup originating from the water/steam)

- Adjust, clean, or replace sight glass for drum level

For the control logic, this to-do list was established:

- Perform full combustion test to fine-tune steam-to-air curves, especially for oil

- Update control logic to current implementation standards

- Adjust logic to indicate when oil/gas is off

- Update excess air calculation

And for tuning, the following:

- Retune loops to be less aggressive

- Reduce output surge and ringing tendencies

- Add a small filter to the level measurement to reduce feed-water chatter

- Reduce filter on old steam flow measurement

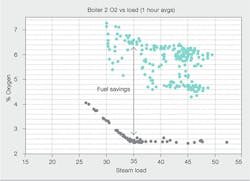

5 Reducing oxygen flow brings significant savings.

As a result of the remedial measures, oxygen readings, which had measured in the 6 to 7 percent range, were brought down to under 5 percent ➔ 5. This reduction in oxygen levels reflects less air drawn in, less air heated up and less air blown out, resulting in substantial fuel savings.

The approximate value in savings was $75,000 for the second boiler alone, and all without major capital investment.

The third boiler exhibited a problem in that it would trip inexplicably during storms. The ABB team traced the source of the problem to an FD fan with a roof intake. The exposed roof position rendered it susceptible to error because wind shear affected measurements from the Pitot tubes coming off the fan intake. Arkema built a protective cover to guard against wind shear and this solved the problem.

As a bonus, it was shown that it was safe to operate the boiler at higher loads, thus getting more out of the installed capital equipment.

In all, the Fingerprint achieved a total annual plant energy savings of around $237,000. As the service cost about $25,000 per boiler, the payback time was very short. The Fingerprint analysis has been applied to other industrial boiler installations, with similar success. As well as reducing energy consumption, the procedure enables clients to reduce their greenhouse gas emissions. As both these topics are likely to become more significant in coming years, so too will the ABB Fingerprint analysis service.

Robert Horton

ABB Optimization Service

Atlanta, GA, United States

[email protected]