Snohomish County PUD Launches Second Energy Storage System

Snohomish County Public Utility District (PUD) has brought on-line its second energy storage system at a utility substation. The battery storage systems aim to transform the marketplace and how utilities manage grid operations. They also are designed to improve reliability and the integration of renewable energy sources, which are rapidly growing in the Pacific Northwest region of the United States.

The projects were made possible in part by a US$7.3 million investment from the Washington State Clean Energy Fund. The Snohomish County PUD’s systems are built using an innovative approach known as Modular Energy Storage Architecture (MESA). It offers a nonproprietary and scalable approach to energy storage. What sets MESA apart from other energy storage efforts is it uses standard interfaces between equipment components, such as the power conversion system, batteries and control system. These provide utilities more choices, reduce the complexity of projects and, ultimately, lower costs.

An industry consortium of electric utilities and technology suppliers developed MESA for the purpose of clearing barriers to growth in energy storage. More than 30 organizations have joined the MESA alliance as members or partners, including Snohomish County PUD, Seattle City Light, Pacific Northwest National Laboratory (PNNL), Duke Energy, Doosan GridTech and General Electric.

Two Systems, Two Technologies

The PUD’s first energy storage system includes two large-scale lithium-ion batteries, one manufactured by GS Yuasa International Ltd. and supplied by Mitsubishi Electric and a second manufactured by LG Chem. Parker Hannifin manufactured the power conversion systems and battery containerization. The system is located at a substation near the utility’s main operations center.

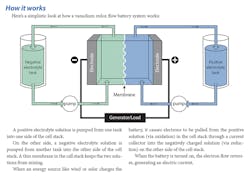

In the spring of 2017, the PUD also completed deployment of multiple advanced vanadium-flow batteries, built by UniEnergy Technologies, at a second PUD substation. By capacity, it is the world’s largest containerized vanadium-flow battery storage system. Together with the lithium-ion batteries, these systems will store enough energy to power nearly 1000 homes for eight hours.

The vanadium-flow batteries and control systems are housed in 20 shipping containers, each 20 ft (6 m) in length, packed with tanks of liquid electrolyte solution. While this technology requires a larger footprint than lithium-ion systems, it can store 70% more energy and has a longer lifetime.

To support the PUD projects, PNNL has developed use cases, or detailed descriptions, of the many ways energy storage can increase renewable energy use as well as how it can improve overall grid efficiency and resiliency. The PUD is actively employing these use cases as it implements and evaluates its energy storage projects. PNNL also is providing analytical and technical support, including conducting benefits analysis, designing test plans and enhancing control strategies.

One of the PUD’s principal partners, Doosan GridTech, is the architect of the MESA software controls. Central to MESA is the goal of standardization. The current energy storage industry is a smorgasbord of batteries, power control systems and voltage converters, all of which have required custom engineering to make the system functional.

One of the challenges with past energy storage projects is each one was its own black-box project. These former projects required a lot of nonrecurring engineering costs to make the battery system talk to the power conversion system as well as the utility systems such as the supervisory control and data acquisition (SCADA) and distribution management system (DMS). The MESA software creates a common thread that ties all these things together in a way that promises to unlock the full potential of energy storage.

Testing and Verification

Prior to deploying the first battery system, the PUD used its test lab — which replicates the actual utility SCADA/energy management system (EMS) and substation systems — to test communications between the battery management systems, power conversion systems, the software controls and SCADA. It helped to identify fixes prior to the launch. The utility checked various control and alarming functions. PUD staff also visited manufacturing facilities for factory acceptance testing to ensure systems were operating correctly, such as charging/discharging and system shutdowns.

The PUD developed a hazardous material management plan to guide staff and local emergency responders. It outlined various protocols, including the process for moving batteries, if needed, and how to handle potential material and chemical spills. The utility has used the plan to conduct training for key staff and its local fire department. By working with its insurance carrier, the utility also verified adequate safeguards were in place. It helped to confirm system requirements for the batteries’ fire-suppression system.

Operational Benefits

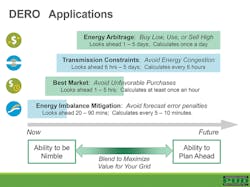

Future energy storage systems could help to resolve a broad range of issues related to electric grid operations. Storage offers benefits related to frequency and voltage support, and it could reduce the need to maintain spinning reserves for backup. Controls integration and optimization software is one of the keystones of the PUD storage program. The control system involves all the different storage batteries, each with its own performance characteristics.

The software is designed to integrate multiple types of renewable energy. The control system infrastructure is the critical technology for utilities and the energy storage industry, advancing from merely demonstrating individual energy storage projects to creating an easily deployable, scalable solution that can be integrated with other grid assets.

For the PUD, storage changes how the utility operates its SCADA and DMS systems because its distribution system has always operated in a one-way direction from generating resources. The utility is working with General Electric to model the distribution system to incorporate energy storage.

Energy storage operational benefits include the significant value of using storage and demand response for arbitrage between periods of high and low demand. During times of the day with high solar energy production, for example, batteries can be fueled for use later in the evening when customers are returning home and demand peaks. When PUD load and market prices are high, there is the potential to draw from the battery to minimize purchases. Local renewable resources provide the fuel, including small hydropower, biogas/biomass, solar and other distributed generation.

In addition, successful energy storage can reduce line congestion and transmission losses. It minimizes the need to run expensive power plants and spill renewable energy during times of excess energy supply.

MESA Origins

The PUD began exploring energy storage systems in 2011 as intermittent resources, such as wind and solar, began to contribute more and more to the utility’s energy portfolio. Battery storage technology is an attractive option, given its relatively small physical footprint, affordable investment costs and minimal permitting requirements. The utility chose to site its storage systems at existing substations, which streamlined the site development and approval process as well as ensured a secure location that could be monitored and easily controlled by staff.

When the PUD looked at existing energy storage systems on the market, it did not find anything with a platform that enabled it to implement multiple, customizable operating modes for various use cases. There was not a system with open standards that met the utility’s need to integrate its software systems for managing the electrical grid, including its SCADA and DMS.

The lack of standards has resulted in battery systems being configured in various ways that do not enable easy integration of multiple components from different vendors. Batteries from various vendors have different direct-current voltage output levels. Manufacturers of power conversion systems have different direct-current and alternating-current voltage output levels. The lack of standards creates additional challenges for utilities and drives up costs. At the same time, communications between components in energy storage systems are inconsistent and lack protocols, which also complicates engineering and drives up costs.

Technology Investments

The PUD’s power scheduling department uses optimizer software to dispatch the batteries remotely for multiple applications. The utility also is designing a Microgrid & Clean Energy Technology Center in northern Snohomish County, which will demonstrate new energy technologies including energy storage, a microgrid system, small-scale renewable energy and an electric-vehicle-to-grid system. The technology center will show how all these technologies can work together to improve grid resiliency, disaster recovery and renewable energy integration. A broad range of new energy concepts will be shared with researchers, teachers, students and the broader community. ♦

Jason Zyskowski is manager of substation engineering for Snohomish County PUD. His work for the PUD has included transmission, protection and substation engineering. He holds a BSEE degree from the University of Washington. He is a member of the IEEE and a registered professional engineer in Washington.

Neil Neroutsos is media liaison for Snohomish County Public Utility District. His experience includes work in energy efficiency, renewable energy development and emergency response. He holds a BA degree in journalism from the University of Washington and an MS degree in public relations from Northwestern University. He is accredited by the Public Relations Society of America.

Sidebar: Energy Storage Outlook

Following is Snohomish County Public Utility Department’s outlook on energy storage:

• Energy storage will become an integral part of the electrical grid.

• Energy storage promises to meet many emerging needs in the electric utility industry.

• Modular Energy Storage Architecture (MESA) represents a flexible storage solution as it is battery agnostic.

• While the cost of energy storage is declining, it is the largest barrier to broader adoption.

MESA 1 Project

The first project consisted of two lithium-ion batteries, for a total of 2 MW and 1 MWh. The first battery was manufactured by GS Yuasa International Ltd. and supplied by Mitsubishi Electric, and the second was manufactured by LG Chem. The power conversion systems and containerization were provided by Parker Hannifin.

MESA 2 Project

The second project consisted of a vanadium-flow battery, for a total of 2.2 MW and 8 MWh. It was manufactured by UniEnergy Technologies.

MESA Goals

Key goals of MESA are as follows:

• Develop standard electrical and communications interfaces to connect batteries, power converters and software components into modular energy storage systems.

• Enable technology suppliers to focus on their core competencies, facilitating quality, safety and cost effectiveness.

• Reduce training costs and improve safety for field staff through standardized procedures for safety and efficiency.

• Help to foster a robust industry ecosystem of modular energy storage component suppliers. By sharing their learning with other electric utilities and technology suppliers, MESA project partners are advancing a new component-based approach to energy storage that gives electric utilities more choice and enables battery, power converter and software manufacturers to reach more customers while focusing on their core competencies.

About the Author

Jason Zyskowski

Manager of Substation Engineering

Jason Zyskowski is manager of substation engineering for Snohomish County PUD. His work for the PUD has included transmission, protection and substation engineering. He holds a BSEE degree from the University of Washington. He is a member of the IEEE and a registered professional engineer in Washington.

Neil Neroutsos

Neil Neroutsos is the media liaison for Snohomish County Public Utility District. His experience includes work in energy efficiency, renewable energy development and emergency response. He holds a BA degree in journalism from the University of Washington and an MS degree in public relations from Northwestern University. He is accredited by the Public Relations Society of America.