According to Navigant Research, North America represents the largest market for software-based centralized volt/volt-ampere-reactive (volt/VAR) control and optimization solutions. Newer software- and analytics-based solutions represent only a portion of the market today — approximately US$65 million — but these solutions are expected to grow rapidly. In fact, this market is expected to approach $200 million in less than 10 years. Technological progress in the form of intelligent controls, advanced communications systems, and sophisticated data and analytics solutions are already enabling utilities to manage voltage and reactive power like never before.

Since the early 1990s, Kansas City Power & Light (KCP&L) has recognized the value of volt/VAR automation and control, and helped to advance industry adoption and innovation of distribution automation (DA) technologies. More than 25 years ago, KCP&L played a major role in the development of some of the first commercially available automated capacitor controls. By 2014, a significant portion of KCP&L’s capacitor automation fleet included nearly 800 aging controls with end-of-life communications. The utility recognized these devices were nearing end of life and began to explore ways to modernize its capacitor bank control fleet.

Modernizing KCP&L’s capacitor bank controls meant simplifying operations and improving communications while maintaining compatibility with legacy field applications and procedures. KCP&L also wanted to reduce communications costs as well as make it easier to deploy and configure capacitor controls. To identify a vendor capable of meeting its needs, KCP&L began a pilot testing process and selected Eaton, given Eaton’s ability to manufacture capacitor controls to meet the utility’s specific needs in a timeline that would maintain an aggressive project schedule.

Integrating New Technology

As utility automation projects mature and are more integrated, technology upgrades become increasingly more challenging. To ease the integration of new technology and reduce the amount of new training for line workers, it is vital for utilities to manage change actively by carefully vetting suppliers capable of providing new control technologies as well as enabling new capabilities that can integrate with existing processes. This challenge becomes particularly important as many emerging DA projects have been jump-started using smart grid funding, and new equipment suppliers continue to emerge to capitalize on market trends.

Unlike KCP&L’s capacitor bank control project two decades earlier, the utility and equipment supplier now had to navigate the design challenges of meeting existing standards, infrastructure needs and processes. The utility also had to find a supplier with the skill set to blend legacy and new solutions, leverage available products and configure off-the-shelf technology.

Having pioneered numerous capacitor control upgrades in the past, KCP&L was no stranger to these challenges and addressed integration with new equipment by focusing on four areas:

• Faceplate design and configuration

• Supplier relationship built on trust

• Working collaboratively

• Refinements for neutral current switching.

Faceplate Design and Configuration

To reduce change management impacts, KCP&L wanted to use existing processes and ensure the new equipment had a similar look and feel for its line workers. Eaton configured the CBC-8000 units to match KCP&L’s legacy systems as closely as possible.

For example, the legacy equipment used two separate switches for remote/local and automatic/manual control, while the new technology enables the same functionality with a single switch. To aid field personnel with this difference, the faceplate was configured with legacy KCP&L naming conventions — an approach that overcame the gap between legacy and new controls as well as accomplished the goal of a similar look and feel.

Other configurations included support for KCP&L’s engineering standards and existing line post current sensors. In the end, these minimized the impact of new technology implementations on KCP&L personnel.

Relationship Built on Trust

The hallmark of success for this project was the relationship between the utility and supplier. It was not simply a matter of selecting equipment that met specifications, but finding a supplier that would be a partner to listen actively to KCP&L.

When the utility identified problems, Eaton believed the challenges were real and worked quickly to find acceptable solutions. This eliminated much of the churn the utility typically encountered and expedited the project. In turn, KCP&L knew its supplier was looking for real ways to address the challenges identified through the project, so the utility accepted solutions faster.

Working Collaboratively

While some of the new capacitor bank controls included features KCP&L sought, the new devices did not meet all the utility’s standards off the shelf. To standardize the way the devices worked in the field, Eaton and KCP&L made creative and collaborative modifications to achieve the desired functionality.

Modifications and feedback from KCP&L were taken seriously. Suppliers investigated solutions that would stand the test of time and collaboratively reviewed proposed modifications with the technical teams involved. The solutions implemented addressed the utility’s current and evolving requirements. This level of true collaboration is a highly valued attribute when selecting vendors.

The following are examples of these kinds of changes:

• Updates and enhancements to firmware for remote supervisory control and data acquisition (SCADA) override capabilities as well as remote time delays based on KCP&L’s recommendation and business needs

• Modifications to the printed-circuit board design to resolve stray voltage detected during KCP&L bench testing

• Updates to the capacitor control’s surge protection to address a potential weakness KCP&L had experienced with other controls

• Boot loader improvements that avoided challenges experienced with firmware updates.

Refinements for Neutral Current Switching

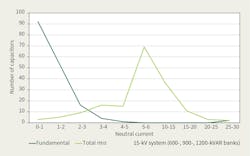

KCP&L worked with its supplier to enhance an algorithm to alarm for neutral fundamental current for blown fuses and stuck oil switches, for example, as well as monitoring and control of total root-mean-square (rms) current to detect closed banks. This enabled the utility to successfully detect capacitor banks in the process of failing, receive positive close confirmations and detect high neutral currents.

Communications Considerations

KCP&L has used two-way communications with capacitor controls for more than 20 years. Part of this specific project included an upgrade of the 20-year-old private system and KCP&L’s current standards, enabling the utility’s capacitors to fall under the same communications umbrella:

• Cellular communications, including 3G and 4G public cellular as well as a small contingent of private cellular

• DNP3 communications protocol

• Web-based platforms with tools for managing KCP&L’s fleet of intelligent electronic devices (IEDs)

• Integration of the web-based platform through LiveData Utilities middleware into KCP&L’s Oracle outage management system (OMS), creating a SCADA-lite experience for KCP&L operators, because they can monitor and control DA equipment directly from the OMS without a separate distribution SCADA system.

The capacitor bank control solution KCP&L selected was designed to integrate a variety of legacy capacitor controls, including the CBC-8000 as the new star of the fleet, and multiple communications radios. The ability to operate the fleet from the OMS and manage the fleet from the web-based tools is powerful. This approach enables utilities to monitor and assess power quality on the distribution circuit and enable automation applications. Utilities also can perform remote over-the-air firmware and settings updates, improving productivity by eliminating site visits and reducing maintenance effort.

Analog Output Point Development

The use of DNP3 analog outputs for controls and set points is an emerging industry trend. Increased intelligence in control and the ability to customize operational algorithms provide powerful support for utility applications, enabling remote analysis of site operations and providing the ability to modify settings without rolling crews, thus reducing labor costs.

Because of KCP&L’s vast experience with automated capacitor controls, the utility collaborated with the supplier to develop new and additional DNP analog output points and some other DNP points to facilitate the ability to change set points over the air. Previously, KCP&L had limited DNP points in its legacy systems. The addition of a 4G-based platform provides nearly unlimited points for more intelligent DA that leverages large quantities of site data to operate and manage the distribution system.

Legacy processes for capacitor automation deployment required many work groups and many steps. Newer technology makes this process nimbler. Now controls are purchased with features to facilitate installation, such as watertight connectors and being radio-ready. With nominal preparation, the control is configured and shipped to a line worker, who installs the control and provides installation data to engineering. This streamlined KCP&L’s deployment process and reduced installation labor by 75%.

Firmware Updates

KCP&L historically managed field firmware updates with a rigorous review and approval process. The utility does not implement the next available firmware release from a vendor unless there is a defined utility-specific business case, and only KCP&L-approved firmware versions can be installed. Validating new firmware takes a combination of bench testing, field testing and analytical analysis before it can be accepted for field deployment by KCP&L. Following this process reduces risk and cost, while maintaining backward compatibility to all operational functionality.

Historically, firmware upgrades were performed when controls were returned from the field, but this led to many different versions being deployed in the field. KCP&L’s current process requires the entire fleet of capacitor controls to be on the same firmware version, which is only practical by remote firmware updates using radios and back-end processes. Remote firmware updates are important to avoid costly truck rolls, and this approach has worked well with the 3G and 4G platforms used on this project.

Integration with OMS

To facilitate this deployment, a KCP&L DA engineer refined and improved a device database and its features to automate workflows between groups on daily device installation. The database eliminates the need for manual data entry in multiple systems and prevents duplicate entries.

Prior to refinement of the device database, managing data for DA devices became increasingly cumbersome, as vital data on disparate systems required users to access multiple applications simultaneously. Users entered data from numerous departments that were responsible for different aspects of the device attributes. These updates were subject to unpredictable delays caused by processes for manually completing paperwork in the field. The paper forms were then scanned and emailed to the responsible group.

The updated device database uses KCP&L’s current production system to leverage centralized device attributes and geographic information system (GIS) information. Approved users can now view, add, edit or delete these attributes. Users can access different interfaces that are now linked together to retrieve centralized attributes.

Engineers use this database and interface to create custom queries quickly and obtain desired attributes on the fly. This updated process enables users to generate electronic field orders on demand.

The OMS integration was accomplished by the teamwork of DA, information technology and field crews. It was achieved with good system design, flexible strategy, careful information selection and configuration, and point-by-point device testing to ensure field conditions are accurately displayed in the OMS interface.

Over recent months, KCP&L successfully integrated CBC-8000 controls into its OMS, which includes integration with web-based cellular communications providers, LiveData Utilities middleware and Oracle’s OMS. Oracle’s OMS uses the LiveData server to exchange real-time telemetry and control requests with real-time systems through standard protocols, such as DNP 3.0, which KCP&L currently uses to exchange data between the Oracle OMS and web-based DA systems. This solution includes monitoring and control directly from the Oracle OMS interface.

KCP&L had two major goals for this integration project: efficiently integrate more than 2000 automated capacitor controls and use its OMS as a single point of control. Accomplishing both goals would reduce operator complexity and serve as a platform for easy integration as the utility scales beyond its current 3500-plus automated devices soon. By leveraging the LiveData Utilities RTI server, KCP&L embedded operational and business logic to make the entire solution work. The utility achieved both goals without the added, and unnecessary, complication of adding a distribution SCADA system into the mix.

Lessons Learned

In broad brush strokes, the level of collaboration, trust and flexibility were the major keys to this project’s success. As the utility identified new technical challenges throughout the initial design and installation phases, it worked collaboratively with its suppliers to address and resolve issues.

For utilities embarking on similar upgrades to centralized volt/VAR control and optimization solutions, the ability to find a supplier able and committed to working through challenges, as well as meeting the equipment specification, is crucial. Although each system and project has unique challenges, the overall approach and commitment to expeditiously working through issues is critical.

KCP&L valued Eaton’s ability to respond quickly to its needs and collaborate toward a solution — an example of the utility and supplier leveraging their respective areas of expertise to solve broader industry challenges. Frequently, suppliers question the validity of a utility’s claims, but Eaton worked as a partner focused on getting the best product possible on the market while recognizing KCP&L’s needs were representative of the needs of the entire evolving utility industry.

The ability to manage change while adopting new technologies was critical throughout the entire project. The challenge often is not in identifying new technologies but in working with new capabilities within an existing framework and procedures to add intelligence as well as abilities without requiring significant retraining and modifications to existing processes.

Going Forward

The application of capacitor automation technology is a proven approach to improve distribution system voltages and power factor, reducing generation demand while achieving significant energy savings and improving customer power quality. Although the initial phases of these projects can be straightforward, a major challenge is upgrading systems over time to meet evolving needs.

As demonstrated by KCP&L, it is vital for utilities embarking on DA modernization projects to manage change actively and properly design new technology, considering existing controls and procedures.

As analysts predict an uptick in newer software- and analytics-based solutions for volt/VAR control, utilities increasingly will face the challenges of upgrading and modernizing systems. This can be far more complex than deploying entirely new capabilities when there is an opportunity to establish something from scratch. Whether the system is entirely new or updated, these projects make it more efficient to automate the electrical grid and enable powerful intelligence that helps to improve reliability and achieve significant cost savings over time.

Acknowledgement

The author expresses appreciation for the technical and project support of Bill Menge, KCP&L smart grid director, the entire KCP&L DA group, and Troy Hedlund, Eaton volt/VAR product manager. Also thanks to Regina Parundik of Cobblestone Communications for developing this article. ♦

Carl R. Goeckeler is a consulting engineer at Kansas City Power & Light (KCP&L) and a registered professional engineer in the state of Missouri, where he earned his BSEE degree at Missouri University of Science and Technology. Goeckeler is an industry pioneer and a leader in the field of distribution automation. He has been recognized for his accomplishments in capacitor automation and led one of the industry’s first major systemwide dynamic voltage control projects. He co-developed the industry’s first integrated communications solutions for DNP devices.

Check out the January 2018 issue for more articles, news and commentary.

About the Author

Carl R. Goeckeler

Carl R. Goeckeler is a consulting engineer at Kansas City Power & Light (KCP&L) and a registered professional engineer in the state of Missouri, where he earned his BSEE degree at Missouri University of Science and Technology. Goeckeler is an industry pioneer and a leader in the field of distribution automation. He has been recognized for his accomplishments in capacitor automation and led one of the industry’s first major systemwide dynamic voltage control projects. He co-developed the industry’s first integrated communications solutions for DNP devices.