Society's quest for sustainable energy is driving a redesign of transmission and distribution networks, from both operational and asset performance perspectives, so that clean, renewable energy resources can be accommodated. Many of these resources are distributed, eg, rooftop-mounted solar panels or onshore wind generators. Battery storage banks, large and small, also play a role.

The new power landscape is a mix of grid-scale and distributed power resources, with an increasing share of small, distributed units – a constellation for which distribution networks were never designed.

The typical distribution network is changing from one that connects producers and consumers in a one-way power flow to one that carries flow in both directions in a complex, dynamic way.

New challenges in the control room

Renewable energy production is dependent on weather and is therefore considered to be intermittent. The energy a wind generator or a solar panel can produce over a longer period, such as a year, can be forecast with a high degree of precision using long-term weather studies. However, daily and hourly production varies considerably and can be accurately predicted only two to three hours ahead. This results in two problems for network operators: The network strength (power available) varies over the day and unexpected power surges and sags can cause rises and drops in voltage, leading to network instability.

The first problem has, so far, been managed by controlling the network strength by adding spinning reserves – conventional and hydropower plants that can be brought online very quickly, exploiting the inertia in the generator rotating mass. The growing number and spread of renewable energy resources on the grid makes this solution less tenable.

Utilities have traditionally countered the second problem, fluctuating power surges and sags, by regulating the reactive power with reactors and capacitor banks. By switching these devices on or off, power flux and voltage change can be minimized. Most modern SCADA energy management systems (EMSs) and advanced distribution management systems (ADMSs) have functionality built in for controlling these units, but they are often manually operated – meaning it is the operators in the control rooms who are responsible for monitoring the SCADA system and taking appropriate action. This was suitable in the traditional network when (usually seasonal) changes occurred only a few times a year, but is much less so now when the networks may need to be reconfigured several times per day, or even per hour.

New solutions to manage the networks

The primary task of a SCADA EMS or ADMS is to manage the network remotely, by gathering data from it, and provide a snapshot at any given time. This includes monitoring analog values such as voltage, current, active power and reactive power as well as the digital state of switching devices. The system will issue an alarm if it detects an abnormal state or if a preset limit is exceeded.

A traditional SCADA EMS or ADMS needs additional functionality to be effective in the modern power network. Here, the key is the integration of information technology (IT) and operational technology (OT) systems. ABB is taking this type of integration a step further by designing and testing integrated functionality during the development of the individual components that make up the final solution. This is made possible by a set of tools that can be combined for full functionality from the start, with less subsequent integration work and low maintenance. At the same time, it is also possible to start with only some of the components and integrate these with legacy systems or systems from other vendors using a more conventional approach.

Grid optimization

Traditionally, the operational mode in the control room can be said to be in one of two states: normal or abnormal running condition. Now there is a third mode, "suboptimal," in which the network is not suffering from major disturbances comma but some power equipment could be run more efficiently and a number of alarms and warnings are present. The alarms keep the operators busy, leaving less time for switching the network into a more optimized and efficient mode or performing planned maintenance activities. In some control rooms, operators are stressed beyond acceptable levels, increasing the likelihood of mistakes. The utilities must, therefore, seek better support when implementing new SCADA EMS and DMS solutions.

"Grid optimization" is the new terminology that describes what needs to be done to manage this situation. Constantly reconfiguring the network by switching capacitor and reactor banks on and off is one example of how voltage levels can be controlled and kept within the limits set out by the regulator. This is referred to as Volt/var optimization (VVO) in transmission networks. Symmetrical loading of transformers, temporarily overloading lines and dynamic line rating (DLR), are other examples of grid optimization techniques that lead to better use of network assets.

But how can operators identify the best time to reconfigure?

Proactive control using forecast data

Calculating the optimal state of the network fast enough to allow preventive switching has always been difficult. The ideal situation would be to foresee and forestall events that lead to alarm conditions. If a network can adapt faster to changing conditions caused by power flux, it can also be operated in a more efficient way – resulting in better utilization and reduced losses. New applications, such as the distribution system optimization (DSO) recently introduced by ABB will help to do this ➔ 1.

1 Block diagram of DSO application components

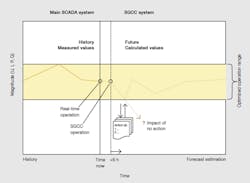

A DSO effectively combines readily available forecast data, such as load and weather data, for input into a software tool that calculates and builds production and load profiles for the near future. Adding this information to the network software function that mimics the network, often in an EMS referred to as the state estimator (SE), results in a simulated network. The network switching states are copied from the real-time SCADA system. The output of these calculations is a simulated network that mimics the real network, but with electrical values estimated a number of hours into the future – the same timeframe as in the forecasts. Typically, this timeframe is six to 12 hours ahead of the current time, which is a good balance between acceptable accuracy and the time needed to reconfigure the network ➔ 2. It also allows time for a signal to be sent to participating units in a customer demand-response program.

2 Network optimization using calculated values based on a six-hour forecast

For the first time ever, the network operator is able to foresee alarms and warnings expected in the near future and make informed, proactive decisions. The result is improved network efficiency, more stable operation and fewer outages.

Demand response

A demand-response management system (DRMS) is a relatively new tool used by utilities to control the balance between the power available and the power needed. The basic idea is to model and aggregate controllable loads into a virtual load that has a lower peak curve. By signaling this load, the utility can control the load profile and better match production at any given hour. It is important to note that, for domestic loads, this solution differs from the older load management systems (LMSs), which controlled loads without the participation or consent of the end users for every switching command that was sent out. The DRMS tool often requires customers to actively sign up to the demandresponse (DR) program.

Typically, signals are sent from a central system to selected program participants, who are able to set up response profiles that, upon receipt of the signal, automatically execute the selected program curtailment option. Suitable loads to control include electric water heaters and temperature-controlling devices such as heat pumps and air conditioners – a small change in room temperature is hardly noticeable to consumers. Less suitable loads include lamps, electric stoves, televisions and computers – for obvious reasons. In return for their flexibility, customers are often rewarded in some way, which varies by utility. Such incentives are seen as a way to change consumption habits in the long term, which is considered by many experts to be the most important behavioral change of all.

Virtual power plants

An aggregation of distributed generation resources managed in a way similar to demand-response loads is called a virtual power plant (VPP). The capability of a VPP would, typically, be comparable to that of a grid-scale renewable power plant. Studies are currently being conducted by research institutes in countries with plentiful wind and solar resources to find economical and technical methods for using VPP units as spinning reserves. Large-scale battery storage, with its ability to smooth power peaks and troughs, is one leading candidate here. The control room engineer needs to take these changes into account when planning network operations.

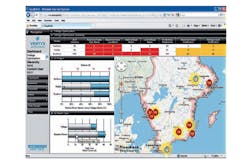

3 Example dashboard using the DSO business intelligence tool

Dashboard

The DSO application features a business analytics software platform that collects information from the simulated network and uses a map to guide the operator to areas where there are alarms and warnings ➔ 3. Business analytics solutions have been used for some time to support decision making, primarily in financial matters, but are now finding their way into control rooms to aid technical decision making. An important function of the business analytics solution is to verify that incoming data is both correct and complete. It can then turn a massive amount of data into actionable information.

E.ON smart grid control center

A new generation of system support is being designed to help utilities manage their increasingly larger and more complex networks. The DSO makes it easier for the operators to follow and foresee changing network conditions. It allows the operators to better manage the increasing quantity of data being made available to them. In a pilot installation at E.ON Sweden, this application will be used in parallel with the SCADA system in the dispatch center to guide the operators, who control a distribution network that provides service to over one million customers. This application will be the first of its kind in the 50 to 130 kV subtransmission network that connects the transmission network with the distribution network. The new system study has been named the E.ON smart grid control center (SGCC).

The pilot installation will run in its own environment with a closed link to the real-time SCADA system and will only suggest actions to be executed. When there is more field experience, a tighter integration will be explored to allow optimization to be carried out directly in the real-time SCADA system. Finally closing the loop will be a major step toward the next generation of advanced distribution system management and optimization. It will allow the control room operators to stay in full control and proactively manage their networks.

Torben Cederberg

ABB Power Systems, Network Management

Västerås, Sweden

[email protected]

Rick Nicholson

ABB Power Systems, Network Management

Boulder, CO, United States

[email protected]