Lightning Tamed

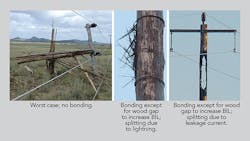

Lightning is one of the major causes of poor performance by medium-voltage overhead lines in distribution networks. On some Eskom medium-voltage networks, for example, up to 78% of equipment failures are the result of lightning activity. Wood-pole splitting and pole-top fires can cause long, frustrating outages and dangerous low-hanging conductors. On medium-voltage overhead line feeders in South Africa, the insulation-to-earth typically comprises an insulator with a 150-kV basic insulation level (BIL) in series with a wood gap consisting of a 150-kV BIL on the bonded wood poles, which offer some power-frequency arc-quenching properties.

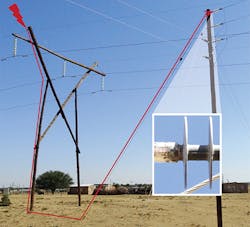

The 300-kV total BIL philosophy currently used by Eskom is based on IEEE Standard 1410-2010 and was implemented to ensure no indirect lightning strikes caused a phase-to-earth flashover. Unfortunately, the higher the BIL, the higher the amplitude of the direct and indirect lightning voltage surges on overhead line feeders, which can increase the number of fuse, surge arrester and transformer failures during lightning storms. A disadvantage of the wood gap’s presence is that direct lightning strikes to the feeder generally cause a flashover across the wood gap, which often results in splintering damage to the wood.

Eskom launched an internal investigation to determine the optimal choice of BIL by instigating on-site measurements on an operational 22-kV overhead line feeder. The pole-mounted supply points were an integral part of the feeder in the field trial to identify the most optimal configuration and protection of the equipment. The utility appreciated the fact direct lightning strikes to the overhead line at a pole-mounted installation caused the largest electrical stresses on the equipment.

Investigating Failures

Eskom had conducted some previous work on four similar 22-kV overhead line feeders that confirmed a large decline in fuse and transformer failures after the BIL was lowered to around 150 kV. Average annual fuse and transformer failures declined from 141 to 12 and 86 to 2, respectively. The main reason for the large number of transformer failures was a result of failed transformer surge arresters remaining in situ.

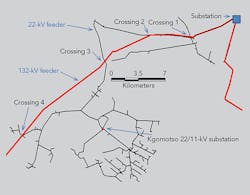

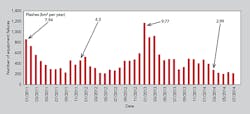

Eskom selected the Ganspan-Kgomotso (GAKG) 22-kV overhead line feeder, which is 156 km (97 miles) long and supplies five small towns comprising 4,350 residential customers and 158 agricultural (irrigation) customers. A total of 372 pole-mounted transformers are connected to the GAKG feeder, which experienced an average annual lightning ground flash density along the feeder of 7.9 flashes/km2/year (20.5 flashes/mile2/year) over a six-year period.

Recording Field Measurements

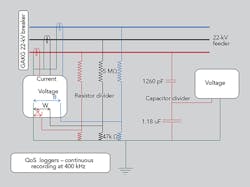

The voltages and currents at the 132/22-kV Ganspan substation were measured with high-speed sampling (400-kHz) Class 4 quality-of-supply (QoS) loggers on the energized 22-kV test feeder. The measurements recorded were then compared with the South African Weather Services Lightning Detection Network (LDN) data, breaker operation alarms from supervisory control and data acquisition (SCADA), and information from the protection relays.

The time (as stamped by GPS) and polarity of the lightning strike, together with the voltage and current waveforms from the QoS loggers (also GPS time-stamped), were used to determine whether the strike was direct or indirect to the feeder. If the recorded transient (leading edge of the first deviation of the waveform) was initially positive while the LDN recorded a negative strike, it meant the strike was indirect. Conversely, if the recorded transient was initially negative (leading edge) with the corresponding LDN recording also indicating a negative strike, it meant the strike was direct.

A resistor divider was used for voltage measurements while the source 22-kV circuit breaker’s current transformers were used for current measurements. A capacitor divider was installed in parallel with the resistor divider to verify the resistor divider did not filter out high frequencies.

Omitting Incidents

A high-frequency voltage oscillation with low amplitude, which occurred simultaneously with a recorded strike resulting in a flashover, was recorded in some instances. It was subsequently found these recorded strikes were close to the crossing points between a 132-kV transmission line and the 22-kV feeder. An investigation showed a strike to the ground wires of the 132-kV line resulted in a rise in the ground potential in the vicinity. Also, a 22-kV wood pole sited in close proximity to this area experienced a voltage potential that exceeded the feeder BIL, causing a back flashover to the 22-kV phase conductors.

These incidents were omitted from the field trial results, as the solution to this problem would have been to increase the BIL of the 22-kV overhead line at this crossing point. This was not considered to be a problem as the chance of a direct strike to the 22-kV overhead line feeder where the BIL was increased is small because of the shielding provided by the ground wires on the adjacent 132-kV line.

A second example where the results were omitted was when the voltage and current recordings suggested a fault caused by lightning, but no recording of lightning could be found on the LDN. With the 22-kV network not being solidly earthed, all the phase potentials could rise with the same polarity, which could be confused with a lightning event.

Installing Equipment

The pole-mounted installations on the 22-kV feeder have a large influence on the performance during lightning storms. Most of the lightning-related failures and outages on the feeder were a result of the failures of the pole-mounted installations.

Annually, thousands of medium-voltage fuses, and hundreds of surge arresters and transformers in the free-state operating unit (part of the Eskom distribution network) fail, particularly during lightning storms. If the equipment-replacement costs and overtime payments incurred to replace this equipment coupled with the wear and tear on vehicles were taken into account, it is evident these equipment failures result in large financial implications as well as a negative impact on customer service.

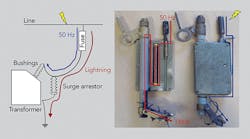

A medium-voltage pole-mounted transformer installation comprises a combination of fuses, surge arresters and the transformer. In a standard installation, the surge arresters protect the transformer against lightning voltage surges and the fuses isolate a faulty transformer. The medium-voltage fuses are directly exposed to lightning current surges as they are installed on the line side of the surge arrester in the standard configuration. These fuses cannot be graded to both withstand the lightning current surges and simultaneously maintain their grading with the upstream feeder protection in the event of pole-mounted equipment failures.

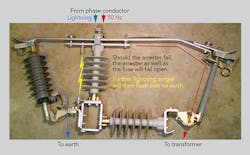

A lightning-proof fuse was developed to withstand the lightning current surges while providing correct grading with the upstream feeder protection. However, should the arrester fail, the transformer is not protected against subsequent lightning voltage surges. An alternative product, the Combi unit, was then developed to protect both a standard fuse and the transformer against lightning voltage surges, even after the surge arrester had failed. The fuse could then be correctly graded with the upstream feeder protection.

The medium-voltage Combi unit consists of a dropout surge arrester and a dropout fuse in a mechanically coupled configuration. Should the arrester fail, the ground lead gets ejected by mechanical action, and the fuse also drops out, thereby isolating the transformer and preventing it from being damaged by subsequent surges.

Analyzing Results

The direct and indirect flashes to and in close proximity to the 22-kV feeder selected for the field trial were recorded. There were no indirect flashes that caused a flashover on the feeder. A total of 72 strikes had amplitudes in excess of 65 kA. Of this number, only eight strikes were direct to the line. Only one direct strike did not cause a breaker operation. The other direct strikes resulted in back flashovers. There were no consequences of the indirect strikes.

Recordings of the three largest indirect strikes were analyzed. One of them was a -72-kA strike that struck a tree some 8 m (26.2 ft) from the 22-kV overhead line feeder. Using the Rusck formula to calculate the induced voltage on a floating conductor, a voltage of 3.35 MV would have been induced on a floating feeder. However, 50 m (164 ft) from the tree was a pole-mounted installation with surge arresters. Taking this into account, the induced voltage would be only 112 kV. The other two large indirect strikes were -120 kA and -99 kA that would have induced 2.98 MV and 3.56 MV on a floating feeder, respectively. However, with surge arresters in close proximity, only 133 kV and 157 kV resulted, respectively.

The SCADA recorded no circuit breaker operations; neither did the recorders register any fault current. Hence, the indirect strikes clearly did not result in a flashover. The GPS coordinate of the strike recorded by the LDN was used to direct a field visit to the site, which revealed badly damaged trees next to the feeder.

The field trial results revealed if this feeder had been built with a BIL of 157 kV, there would have been only one flashover due to an indirect strike during the six-year measurement period. However, the IEEE standard predicts 13.5 flashovers would have occurred. The IEEE analysis is based on no surge arresters being installed on the 22-kV feeder and no tall objects adjacent to the overhead line. In practice, there were 1,116 arresters on the 22-kV overhead line feeder and many tall objects in close proximity to the feeder that would have contributed to the difference. Therefore, it is reasonable to assume if a utility chooses to have no flashovers due to indirect strikes, it would be considered safe to build the overhead line feeder with a BIL of 180 kV. This would be a good choice, as in most cases, some additional insulation over and above the insulator would be required to ensure the pole top was bird friendly.

Finally, if the trees had not been in close proximity to the line, the three largest strikes would have been direct to the feeder and, thus, would not have counted as indirect strikes. The highest induced voltage as a result of indirect strikes over the six-year period then would be less than 111 kV.

Looking Forward

Several thousand Combi units were manufactured by Live Line Technology and installed as a trial site on 11-kV and 22-kV feeders. Some results were shared in the “Lightning and Power Frequency Performance on Medium-Voltage Pole-Mounted Transformers” presentation at the 7th Southern Africa Regional Conference & Joint Colloquium in 2013. The final product is currently being evaluated. Eskom is currently evaluating practical ways to lower the BIL on wood poles while complying with environmental requirements.

Willem Jacobus Dirkse van Schalkwyk received a master’s degree in engineering at Stellenbosch University in 2001 in the field of high-voltage engineering, and he is now a chief engineer in Eskom Holdings SOC in South Africa. Van Schalkwyk, who has been employed with Eskom since 1985 in the system operations environment, is a registered professional engineer and member of the South African Institute of Electrical Engineers.

John Michael Van Coller is a senior lecturer with the school of electrical and information engineering at the University of the Witwatersrand, Johannesburg, South Africa. He holds a Ph.D. from the same university in the field of high-voltage engineering. Van Coller is a member of the IEEE and Institution of Engineering and Technology, and he is involved with the Eskom Power Plant Engineering Institute, which provides specialist postgraduate training for Eskom employees.