The archipelago of Åland consists of 6500 named islands out of some 20,000 skerries and smaller islands. The total number of inhabitants is 28,900, of which 11,000 live in the only town, Mariehamn. The electricity supply is managed in the same manner as in any country with a deregulated electricity industry, but on a miniature scale. Kraftnät Åland AB, the main transmission system operator (TSO), is responsible for the operation of the 110-kV and 45-kV transmission systems that link all the inhabited islands.

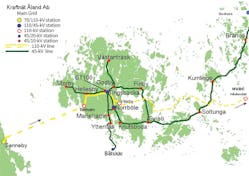

The Kraftnät Åland transmission system comprises 26.4 km (16.4 miles) of overhead lines and 62.9 km (39.1 miles) of cable at 110 kV, as well as 164.1 km (102 miles) of overhead lines and 96.8 km (60.2 miles) of cable at 45 kV. There are 22 110/45-kV substations. Two separate utilities are responsible for the 10-kV distribution network, with one supplying all customers residing outside the Mariehamn limits and the other supplying all customers residing in Mariehamn. Additionally, several utilities operate wind farms.

An existing single submarine cable interconnection with Sweden failed to provide a reliable supply, and the utility was concerned about the consequences if the submarine cable failed. The utility’s immediate response was to install a larger gas turbine, but this failed to resolve the problem. Therefore, the utility decided to install a high-capacity interconnector with mainland Finland.

Existing Power Supply

Since 1973, the archipelago of Åland’s main source of supply has been from Sweden, originally connected by three 84-kV single-core submarine cables with a circuit rating of 35 MVA. However, the load-transfer capability of this interconnection was insufficient to satisfy the winter peak demand. Additional power was produced by three diesel generators and two gas turbines with a combined capacity of 50 MVA. To reduce the demand for power, cooling water from the diesel generation plant was used to provide a district heating system for residents in Mariehamn.

Following some 20 years in operation, this combined transmission and generation system was deemed inadequate because of the generating plant’s age and the submarine cable link’s deterioration. As a replacement, an alternating-current (AC) link with Sweden was installed in 2000 to form the main source of supply. This link is a single 110-kV three-phase submarine cable with a circuit rating of 80 MVA. The submarine cable connection is 60 km (37.3 miles) long and requires reactors as well as capacitor banks at each end to balance the reactive power.

In addition to the main connection with Sweden, there also is a 45-kV connection with mainland Finland. Sections of overhead lines and submarine cables connected the central archipelago with Finland. This 45-kV interconnection is rated 10 MVA at the supply end, with approximately 4 MVA available at the final receiving end. This link cannot be synchronized with the link to Sweden because it would result in uncontrolled power flows.

Existing Supply Reliability

The existing interconnection with Sweden failed to provide a reliable supply, and the utility was concerned about the consequences if the single submarine cable failed. It was estimated repair of the submarine cable could take up to 100 days, with most of the time being attributable to locating the fault and contracting a ship with the capability to repair the fault. The utility’s immediate response was to install a larger 25-MVA gas turbine, which was commissioned in 2005. However, the turbine failed to resolve the problem.

A trial run in islanded operational mode highlighted problems, which were basically a result of insufficient staff. Kraftnät Åland is a small utility with insufficient resources for 24/7 manning of the generating plant and main control room, so the trial had to be stopped after just 24 hours. In 2005, the total number of staff operating the TSO was 10, including the managing director. Today, the number of staff is 15.

The utility determined the only viable solution to establish a reliable supply was to install a high-capacity interconnector from mainland Finland. A second cable from Sweden was considered and rejected because it would have required installation along the same route as the existing cable. The existing submarine cable had experienced numerous faults, with the most serious being caused by ships dragging anchors across the cable. Hence, there was a risk the second cable would be vulnerable to the same issues.

HVDC Interconnector

In 2009, Kraftnät Åland awarded an engineering, procurement and construction (EPC) contract to Pöyry SwedPower AB (now Pöyry Sweden AB) for a 130-MVA high-voltage direct-current (HVDC) link from Åland to mainland Finland. The 156-km (97-mile) route length was too long for a high-voltage AC submarine cable link; therefore, the utility opted to install a 130-MVA HVDC interconnection. One main design prerequisite was that the HVDC link must be able to do a black start without any local generation. As a result, a system using a voltage source converter was required. It was determined the rating should be 100 MVA, with an additional 30 MVAR to enable large motors to start. This circuit rating was sufficient to meet the expected increase of demand for the next 30 years. The peak demand on the island to date was measured in January 2016 as 70.6 MWh between 5 p.m. and 6 p.m.

Following a protracted tendering process, contracts for the supply of the converters and the 110-kV submarine cables were awarded to ABB in December 2012. Separate contracts were signed for the extension of the 110-kV network to include the HVDC converter station on Åland.

In response to a request by fishing authorities, the utility completed a route survey for the submarine cable in advance and repeated it over a few sections. The cable interconnection consists of two ±80-kV cables, with this voltage level being the most appropriate for the specified power-transfer capacity. The two cables are bundled together with a fiber-optic cable for communication purposes.

The bundled cables are laid directly on the seabed for the majority of the route. At each end of the route, the cables are laid in polyvinyl chloride (PVC) ducts to prevent damage from anchors and so forth. At the Finnish mainland end, the cables cross an inlet to a busy commercial port, so the PVC ducts are covered by rock backfill. In one section of the route, the cables are laid in an area subject to trawler fishing activities; in this section, the cable bundle was buried below the seabed in a trench created by water jetting.

At the Finnish end, the converter station is located in close proximity to a 70/110-kV substation operated by Fingrid, Finland’s TSO. This substation is now scheduled to be upgraded to 400 kV, a project that will enhance the availability of power supply to Åland.

The HVDC submarine cable interconnector is designed for completely unmanned operation. Start and stop, as well as any settings, can be handled automatically in case of emergencies or manually from the dispatch center of Kraftnät Åland in case of planned actions.

Commissioning and Trials

The project equipment was energized and commissioned in sections until November 2015, when the interconnector was completed and ready for power-transfer trials. An interesting event occurred during the maximum load-transfer test. To have full control, power was transferred from Åland to Finland with the AC connection from Sweden in operation and the gas turbine operating at full 25-MVA power. In addition, there was production of some 20 MW from the wind power plants and full-load local backup generation.

When the power transfer had been increased to 90 MW, a local generation unit suddenly failed, causing the link from Sweden to trip due to overload. The islands suffered a momentary blackout. The emergency power control of the HVDC link took over, and within three cycles, it transferred 30 MW to Åland. The majority of customers did not even notice more than a quick dip in lights; the fault was actually rectified faster than the rapid auto-reclosing on an AC network. However, the supply restoration was too fast and caused some problems for the wind power producers.

The converter station on Åland is situated in a recreational area with a small harbor and a few cottages. In these rural areas, the emitted sound level must be below 35 dBA. Therefore, measures had to be taken to reduce the noise emission, including the provision of transformer noise housings and noise baffles around the cooling system. During the operational trials, the noise emission was measured to verify it was within the specified limits. The only problem was a woodpecker among the trees behind the converter was so noisy it completely overrode the noise from the converter. Once the bird moved on, the noise emission from the converter was well below 35 dBA.

Operational Procedures

The main purpose of the existing 45-kV connection between Finland and the archipelago is to supply power to the islands between the main island and the Finnish headland. This link cannot be synchronized with the Swedish network, so disconnection facilities are installed to provide an open point to prevent the risk of paralleling the Finnish and Swedish systems. The open point can be moved to permit routine maintenance work, but in executing this change in open point, the operational procedures resulted in customers experiencing a short-term outage.

To overcome this operational problem, the HVDC link takes over the load from the AC connection with Sweden and isolates the 45-kV cable connection before starting to synchronize the 45-kV network on Åland and with the 45-kV network from the Finnish mainland. Once the correct phasor location is achieved, a signal is sent to Kraftnät Åland’s load dispatch center that the open circuit breaker can be closed. The circuit breaker at the point of disconnection then can be tripped and the disconnectors opened.

On completion of operations, a signal is sent to the HVDC control to resynchronize the 110-kV system with the Swedish network by reclosing the 110-kV circuit breaker. To achieve this operational procedure, phasors are measured at both end points of the 45-kV circuit. The only problem with this installation was identifying a communications protocol that would be fast enough to handle the communications network operator over the distance between the 45-kV substation in Finland and the HVDC converter station. The fiber-optic cable connection on Åland was handled by Kraftnät Åland, which installed an appropriate and efficient protocol.

Control of the HVDC converters had to be provided with a function for very slow action and fine-tuning of the frequency to maintain a stable connection for the 45-kV system.

Remaining Issues

The HVDC link was fully commissioned following completion of the project in December 2015. However, one operational problem remains: when the HVDC link is supplying the archipelago in islanded mode, without the 110-kV interconnection from Sweden and without any gas turbine in operation, there is a lack of short-circuit current in the system. In the event of a fault, the HVDC link will increase current up to its maximum load-transfer capacity. If there is insufficient fault current, the converter will decrease the voltage until the situation has stabilized.

On the 45-kV transmission system, the overhead lines are typically protected by overcurrent protection. The system is impedance earthed, which means earth faults, both single phase and two phase, can be handled by the in-service protection. However, three-phase short circuits will not be detected with enough security, so this problem remains under investigation. The small 110-kV system that links the converters with substations at both ends is protected by line differential protections and, therefore, does not require short-circuit power. Line differential protection is available but considered too expensive to be installed on the extensive 45-kV network. ♦

Acknowledgement

The author wishes to acknowledge the support and technical information given by Jan Kahlroth, managing director of Kraftnät Åland AB, in the preparation of this article.

Claes Malcolm is a senior engineer at Pöyry Sweden AB, with more than 40 years of experience in high-voltage design and control equipment. Malcolm has been actively involved in International Electrotechnical Commission (IEC) standards, with participation on IEC TC57 (power system management and associated communication). He has served as the convener of IEC TC57 WG18 (hydroelectric power plants, steam and gas turbines – data models for monitoring and control) as well as on the Swedish Committee for TC95 (measuring relays and protective equipment). In 2007, Malcolm received the IEC 1906.