Tired of the phrase Big Data? What is big data, really? Just how valuable could massive amounts of data really be? There also are those threes Vs of big data: volume, velocity and variety.

Think about substations. Is really big data flowing from the substations? What about the struggle to get data from the system? From a substation perspective, is there really a data overload? The answers depend on whom is asked the question.

New sensors are being developed and tested every day. Sensor development is great; however, the ability to plug those sensors into existing substation communications structure is the real challenge. One reason for this challenge is the ability to tie new data into existing systems because of the existing information technology infrastructure. Another reason is shrinking operations and maintenance budgets. And, there are other challenges such as resource constraints for the work that must occur after sensors and monitors are installed in a substation.

Recognize Good Data

With all the challenges of getting data out of substations, it is important for utilities to recognize good data. Good data is reliable and subject-matter experts value it as credible. Good data helps a utility understand its substation assets. If data from sensors and monitors is not good, a utility is wasting its money on monitoring equipment. Another issue, if the data is not credible, is a utility making poor decisions such as taking a transformer out of service years before it is necessary or performing breaker maintenance on a unit in excellent condition.

The other side of this issue is a utility being unaware of an asset that is a ticking time bomb. Unreliable data reliably leads to these situations. If a failure were to occur and a data review showed normal conditions, a lot of questions would be raised, and the future of monitoring and a condition-based maintenance (CBM) program could be discredited or at risk for termination.

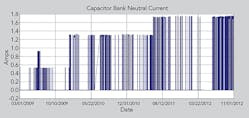

How does one tell if data is good or bad? In looking at the figure above, is this good or bad data? It is good data. Over time, the values go up. This is the neutral current on a capacitor bank. The data clearly showed a problem developing, which was resolved before it became an issue. Think about where the data comes from and verify that the sensor technology is not only good technology but that it is reliable for the long term. Testing and knowing the accuracy of monitoring equipment is necessary to ensure the data from these devices is good. Getting good data out of monitoring equipment extends beyond the monitor itself, and without reliable communications to the monitoring equipment, all data is bad.

Communication Is Key

First and foremost, communication is the key to success when it comes to good data and an effective CBM program. The question is this: Does a workable substation communications protocol standard exist? This will determine how to move forward with the communications requirements for sensor and monitoring equipment. If no standard is in place, it is time to act and determine which protocol works best, and someone within the utility must have experience with that protocol. It is recommended the monitoring equipment follow the substation communications protocol standard.

More or less, think in terms of the KISS principle of keeping it simple. The major warning from lessons learned is to avoid vendor-proprietary protocols if at all possible. Automatic data movement from a sensor into the CBM program is difficult to impossible using a vendor-proprietary protocol. Data from devices with the standard protocol is easier to integrate into an existing system, and those performing the integration also are familiar and comfortable with the protocol. Another benefit of using a standard protocol is no one has to learn several vendor packages.

Challenges, Challenges

The vendor proprietary protocol is one challenge Southern Company Transmission has encountered in piloting CBM. The solution is to purchase only sensors and monitors that follow the DNP3 or Modbus protocol. Existing monitoring equipment that is not DNP3 or Modbus compliant must be converted over time to the standard communications protocol based on several factors such as resources and budgets. Some monitors may not be converted because of funding and resource constraints, which means access to the data will be difficult for automatic data movement.

In some cases, the work-around is to equip these monitors with a cell modem and rely on the programming skills of information technology (IT) to automate the vendor software tools for data extraction, developing a program to move the data from the vendor software to the data historian. As of now, there is a lot of manual data entry from these devices into the data historian. Although this semi-automation is not the standard, it will exist in special circumstances until all monitors are upgraded or replaced.

Unfortunately, that is just the first challenge of getting data out of substations. Because it has an impact on moving CBM forward, standards are being developed for the design and purchase of new monitoring equipment that includes requirements around communications.

Another challenge that may be a bit more surprising involves microprocessor-based relays. The benefit is these relays provide a wealth of information about breakers, capacitor banks, close-coupled voltage transformers, transformers and transmission lines. The problem is, because of available bandwidth, only a limited number of values are brought back through supervisory control and data acquisition. The data needed to understand fault information is typically buried in the relay event files, which are cryptic text files that need special software to parse out the fault data points and push the data to the data historian. Yes, this software exists, and, yes, it works.

It is dependent on a few things, including a specific naming convention and manual programming work for integration with where the parsed data will be stored. It also is dependent on resources to set up the file system and check to ensure the file parser is working, as in data is moved to the correct locations. A work-around is the newer relays include fault information in a DNP format and use the existing IT infrastructure to push the fault data points to the CBM program. This will assist in moving forward with breaker health assessments while time can be spent as resources are available to work through the issues around the file parser software.

That brings up another issue, which is dedicated resources to manage CBM. As Southern Company Transmission’s CBM pilot moves to a program, the CBM team consists of one employee assisted by a part-time contract programmer. A lot of coordination exists with protection and controls (P&C), and the substation integration and automation (SIA) engineers. No good data would exist in the program if it were not for their support and assistance in the field.

CBM Governance

Recognizing the challenges in developing and maintaining good data is the first step toward making the transition to a CBM program. Another useful tidbit from Southern Company Transmission’s CBM pilot as it moves to a program includes a governance team. This team was established to maintain focus on CBM and move it forward. The governance team consists of representation from all invested parties including information technology. The first act of the team at Southern Company Transmission was to establish several working groups around the key challenges. This included a working group for communications, design standards and standard monitoring equipment.

The other working groups are focused on areas of importance to CBM and include working with the subject-matter experts across the system to learn from their experiences, capture their valuable experiences and incorporate that knowledge into asset health score algorithms for transformers and circuit breakers. This 0-100 scale score is only as good as the data behind it, so, once again, good data is important to generate a reliable health score. The purpose of this score will be used to understand assets better as well as in maintenance planning and capital replacement project planning.

The Good News

Conquering the challenges of CBM consists of trial and error. So, do not be discouraged and keep thinking of ways to overcome the challenges of accessing good data from substations. As mentioned, there are numerous challenges to Southern Company Transmission’s CBM program, and there have been even more trials and tests conducted to find ways to overcome some of these challenges.

Build a network of those who face similar struggles around collecting good data and using that data for CBM. The good news is good data can be turned into actionable information and used to change how one views a substation. If used correctly, the data can give substation assets a voice. There are endless possibilities to how good data can be useful in substation operation and maintenance in the

future.

Elizabeth Bray ([email protected]) is the project manager for the condition-based maintenance program at Southern Company Transmission, where she has worked for eight years. Prior to joining Southern Company, she worked for American Cast Iron Pipe Co. as a controls and design engineer. Bray received her BSEE degree from the University of Alabama and her master’s degree from Mississippi State University. She is a registered professional engineer in the state of Alabama and an active IEEE Power & Energy Society member.