As summer winds down in most of the U.S., it is still balmy in the South. In a time of increasingly heightened demand for electricity, many utilities like Morristown Utility Systems (MUS) are using the opportunity to implement advanced metering infrastructure (AMI) and demand-driven programs designed to shave peaks, reduce cost and increase operational efficiency. A multiservice utility serving nearly 15,000 electrical, 12,000 water/wastewater and 5,800 telecom customers in eastern Tennessee, MUS has completed deployment of a fiber-to-the-home (FTTH)-based TUNet AMI network and endpoints, becoming just the third utility in the state to use FTTH for data communications.

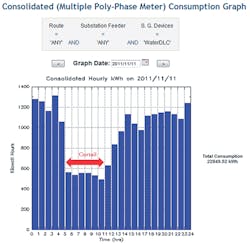

With an AMI communications infrastructure now in place, MUS is broadening its focus on value-add programs and applications like load management designed to improve operational performance and reduce peak demand up to 4% systemwide, thereby reducing wholesale cost.

Leading the Charge

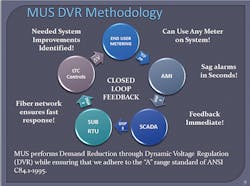

As part of a Tennessee Valley Authority (TVA) smart grid pilot project, MUS is partnering with its generator, TVA, to curtail load at TVA’s day-ahead request for up to 100 hours per year. This initiative is part of TVA’s five-year plan to combine energy efficiency and demand response to achieve systemwide savings goals of 2.9% by 2015 and 5.4% by 2020. Eventually, this project will help to lower TVA’s overall peak demand, reduce the need for additional power plant construction and avoid the need for distributors to make costly power purchases off the grid. The project requires MUS to perform closed-loop voltage reduction (CLVR) to deliver load reduction and operate during the period within the American National Standards Institute (ANSI) voltages limits.

MUS is one of several distributors who received funding through grants from TVA to explore new demand management technologies, glean valuable lessons and help to replicate success for distributors throughout the Tennessee Valley. Project funds were awarded through a competitive selection process based on merit, potential value and potential cost savings to both the utility and its consumers.

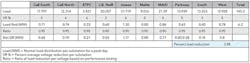

In service to its customers, MUS is always looking for new ways to improve its operations and manage costs. One way the utility is demonstrating that commitment is by using CLVR to shave its own peak billed demand. Beginning in April 2011, TVA returned to the practice of billing power distributors for their maximum 1-hour peak monthly demand. Like many other distributors, MUS’s peak is not coincident with TVA’s peaks, so MUS must track its own load and perform CLVR as needed to accurately predict and pay for peak demand. Accuracy of data translates to dollars spent and saved, thus making data management and control tools crucial for the utility to audit voltage status effectively and reduce thousands of dollars off its wholesale power bill.

Additionally, the introduction of real-time alarms and voltages into supervisory control and data acquisition (SCADA) opens the door for automating existing conservation voltage reduction (CVR) programs. In practice, the ability to port low-voltage alarms from selected meters in TUNet, the Tantalus utility network, directly into SCADA provides, for the first time, a tool for dispatchers to monitor voltage conditions across the feeders in real time and respond accordingly to maintain adequate voltage. It provides an online health check that monitors the pulse of the electric system.

CLVR Introduction

CLVR is one of the most simple, cost-effective ways utilities can manage loads to reduce peak electrical demand immediately. Unlike traditional CVR, in which voltage is lowered to decrease overall annual energy consumption, CLVR provides the utility with the capability to shift load and reduce peak demand. By combining AMI with SCADA, CLVR provides a way to monitor and adjust voltage on the fly automatically, maximize the effectiveness of voltage regulation efforts and maintain end-of-line voltages within regulatory limits.

The key benefits of CLVR for utilities are as follows:

• Reduces demand charges immediately

• Serves as a virtually invisible program to the consumer

• Requires no consumer marketing programs or buy in

• Is rapidly deployable (up and running within hours)

• Maximizes the effectiveness of voltage reduction programs

• Identifies unrecognized inefficiencies in the existing power grid.

CLVR is designed to decrease a utility’s total electrical load in anticipation of a peak event by making slight reductions in the feeder voltages coming from substations. For example, on a hot summer day, when the demand on a utility’s generation capacity is strained and approaching peak, CLVR applications acknowledge the peak and immediately act to temporarily decrease voltage. Appliances, lighting, resistive heating and certain types of motors will immediately draw less power yet still perform within acceptable levels. Although the reduction is slight and power quality remains within adequate regulatory tolerances, the cumulative impact of thousands of electrical devices simultaneously using less power has a significant impact on a utility’s load.

While voltage control as a means of demand management is not a new concept and has been deployed by many utilities over the years, recent advances in the quality, automation and real-time nature of certain AMI communication and data management technologies have significantly multiplied the usefulness of meter data. In turn, this has translated to increased control and power quality.

Shifting Demand

When electric demand exceeds available power, brownouts, blackouts and the need to purchase expensive wholesale power can occur. This risk makes the proactive management of such peak loads critical to maintaining grid reliability and managing utility costs. Using AMI-enabled tools like CLVR helps the utility to manage peak load by responding to peak reduction requests with immediately dispatchable voltage reduction commands. Furthermore, instantaneous feedback from the AMI system on the voltage impact of CLVR provides utility decision makers with the real-time system visibility needed to make additional decisions to reduce overall load, if needed.

Thermostatically controlled devices provide another classic example of how CLVR can be used to shift load. With CLVR, devices such as electric heaters, heat pumps, stoves and refrigerators may run for slightly longer periods of time to reach their desired temperatures but will also draw less power under carefully monitored CLVR. The impact of this application during peak times results in a reduction, or smoothing, of peak load.

With the right real-time smart grid communications platform, CLVR can be used throughout the day to lower voltages during peak periods and increase voltages during off-peak periods. TUNet offers real-time TRUPUSH functionality, which, when integrated with a utility’s SCADA system, proactively monitors, notifies and enables the control of feeder voltages within seconds. Continuous data feedback allows operators to monitor line voltages and alerts while making adjustments as necessary. The Tantalus voltage reduction application enables the utility to reduce peak electrical demand over time while ensuring customers’ service voltages stay inside acceptable levels.

Safety in Numbers

Properly conducted CLVR is safe for electrical equipment, which is designed to operate with some voltage flexibility in mind. In North America, end-use voltages in the range of 114 V to 126 V are standard (range A in ANSI standard C84.1) and provide the variance needed for CLVR. Smart meters supported by a robust real-time communications network can monitor voltage throughout a grid to ensure levels remain within a prescribed range. As such, demand management programs like CLVR are one of many high-value benefits offered by a flexible, reliable smart grid communications network.

TUNet is designed in a way that supports safe, effective CLVR. With TUNet’s AMI network, each meter continuously monitors many aspects of power. For instance, TUNet devices check line voltages several times a second, 24 hours a day, 365 days a year. If the voltage exceeds or drops below preset levels at any endpoint, the meter can immediately report this change in power quality by using TRUPUSH-event driven, command and control communications to push alerts and status updates in real time. The ability to manage thousands of smart devices optimally on an electric grid in this manner is unprecedented historically.

The AMI Advantage

A cornerstone feature of two-way AMI is its ability to acknowledge and transmit real-time notifications. This feature ensures, during a CLVR period, the utility receives real-time voltage alerts from any meter reaching its threshold. To take this a step further, integrating a voltage reduction application with SCADA systems provides an automated way to ensure maximized CLVR savings while maintaining reliable customer power quality. The main advantages of automated demand management include the following:

1. Labor savings, by eliminating the need for operational personnel to monitor load continuously

2. The ability to deploy at multiple locations concurrently

3. The ability to handle unanticipated load peaks.

Demand management through voltage reduction requires little infrastructure beyond AMI and SCADA. Tantalus is continuously improving existing feature sets like its recently unveiled DNP3 interface for the delivery of voltage alert data from selected meters to the SCADA system. Developed in conjunction with the Efacec Advanced Control Systems SCADA system and deployed with MUS’s high-speed FiberNET, this low-latency AMI-DNP3 interface delivers voltage sag alarms to the MUS SCADA system within seconds of any detection of a voltage event by any affected meter, including those deployed near the end of the line or at any strategic point in the distribution system.

TUNet’s real-time capability lies in the design and architecture of the hybrid-mesh 900-MHz local area network, which allows timely voltage data from all of the smart meters to reach the SCADA system for optimal decision making.

Effects and Results

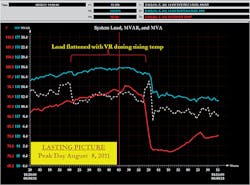

MUS’s experiences in implementing a real-time demand management program have proven highly effective for reducing demand from the utility side without impacting the convenience of the consumer. In fact, this behind-the-scenes program works so seamlessly with the AMI network that customers experience no discernible drop in power quality while the utility is able to meet its goal of reducing system voltage by up to 4% during peak.

For this program, MUS uses its ultra-high, gigabit-speed fiber network along with two-way communicating load management devices installed at substation voltage regulators for scheduled or on-demand curtailment. The distinctive push-type feature of the network ensures operators receive fresh data consistently with the ability to dial back voltage with more precision. The results of this program are very promising with MUS already on track to realize a significant net reduction in wholesale power cost in excess of US$1.5 million since April 2011.

Because of the flexibility real-time AMI provides, MUS can use a suite of advanced metering and demand management solutions while relying on a common, unified network. This advantage is clearly demonstrated by MUS’s use of various features within its demand management application suite. Not only can MUS use the network to leverage the CLVR program, it can expand its demand management options to include the management of distributed generation sources, commercial and industrial applications, and utility water-pumping demand reduction as opposed to traditional constant CVR alternatives. This program allows MUS to pursue multiple business goals strategically at once while multiplying the effectiveness of their overall demand management initiatives.

Through AMI-enabled demand management, MUS is able to address two of its primary goals:

• Implement cost saving and energy-efficient technologies to keep rates low

• Optimize operations throughout its service area.

The ability to detect situations quickly where it could reduce line voltage to the ideal level is helping make MUS’s network more efficient and saving the utility money every day. This allows MUS to reduce its annual energy consumption and peak load, as well as easily monitor potential system problems.

In achieving MUS’s efficiency goals over the long term, demand management programs like CLVR will continue to provide a wealth of knowledge to identify weaknesses and inefficiencies in the power grid. In Morristown, all voltage reduction is performed by load-tap changers at the substation transformer. This means all feeders are reduced by the same percentage voltage drop so the amount of load delivered is inherently limited by the weakest feeder. MUS plans to use this and other lessons learned during CLVR events to improve overall voltage profiles and deliver more flexibility in demand regulation.

In addition to numerous utility benefits, reducing peak demand has long-term benefits for the citizens of Morristown. By implementing effective tools to manage peak demand, the utility is able to avoid inconvenient and dangerous brownouts and blackouts while improving service quality. Effective peak management tools allow distribution utilities to reduce peak demand charges. When several utilities participate in reducing peak demand, it allows generation utilities to defer the purchase of expensive new power plants, which works to keep rates low. CLVR is both effective and consumer friendly, making it an ideal choice for utilities looking for easily implemented demand management solutions.

Acknowledgement

The author would like to thank the team at Tantalus for its partnership in making MUS’s demand management program a successful means to save money and energy.

Joseph S. Wigington ([email protected]) is a registered professional engineer with more than 35 years of experience in the utility and manufacturing industries. After positions with TVA and the BASF Corp., he joined Morristown Utility Systems in 1995 and has served as general manager since 2007. In his current role, as general manager and CEO, he is responsible for managing utility operations to provide power, water, wastewater and broadband fiber telecommunications services for the city of Morristown, Tennessee.

Mentioned in this article:

Efacec ACS | www.efacecusa.com

Itron | www.itron.com

Tantalus | www.tantalus.com