California Utility Constructs Peak-Shaving Storage Facility

Traditionally, as the load on the distribution system grows, additional infrastructure must be provided to increase the capacity of the local substation. However, with the proliferation of distributed energy resources, the traditional planning paradigm is changing. The concept of deferring an asset upgrade is nothing new, but new technologies have provided opportunities to harness potential stacked benefits and future flexibility to serve the unique challenges of the distribution system. One technology being adopted in California is utility-scale battery energy storage systems (BESSs) which can enable deferral of costly system upgrades, help balance supply and demand on the transmission grid, and help integrate renewables.

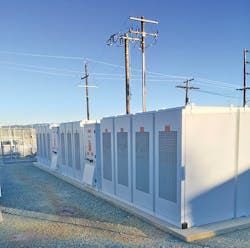

For example, 50 miles north of Sacramento in Browns Valley, California, Pacific Gas and Electric Co. (PG&E) recently deployed its first lithium-ion energy storage facility, which features 22 Tesla Powerpacks for a combined facility size of 500 kW/2000 kWh. Each about the size of a refrigerator, the Powerpacks, which feature a modular design adapted from Tesla’s electric vehicle technology, will help PG&E address peak demand on the substation and improve power quality and reliability.

Funded through the Electric Program Investment Charge (EPIC) program, PG&E worked with Cupertino Electric, a San Jose, California-based electrical engineering and construction firm, to design and install the system and kick off the project, titled EPIC 1.02 – Energy Storage for Distribution Operations.

The EPIC program enables California investor-owned utilities to develop smart grid technology demonstration and deployment projects, and evaluate how they support safety, reliability and affordability objectives for the benefit of their customers.

Addressing Peak Demand

The Browns Valley energy storage facility is tied directly into PG&E’s supervisory control and data acquisition (SCADA) system and autonomously shaves load peaks at the local distribution substation based on real-time load data. When load approaches the design capacity of the substation, the Browns Valley energy storage system will discharge to provide the necessary relief to keep the substation equipment below its electrical and thermal limits. When the load decreases below a comfortable level, the energy storage system will be permitted to charge and replenish the energy used to shave the load peak. Overall, the facility will be able to provide up to 500 kW of power to address potential overloading on the substation equipment.

By building the new facility and testing key functionalities through the EPIC program, PG&E is exploring how best to meet the regulations set forth by California’s energy storage mandate. The utility is working with San Diego Gas & Electric (SDG&E) and Southern California Edison (SCE) to accomplish the targeted interconnection of 1.3 GW of energy storage resources by 2024, with much of these facilities either directly or indirectly enabling increased renewable generation on the grid.

In addition to being PG&E’s first lithium-ion storage facility, Browns Valley also represents the first time a Tesla energy storage system has been fully integrated into a utility SCADA system. While the facility performs peak-shaving autonomously on a typical day, PG&E can also manually schedule or directly dispatch the energy storage system at any time.

Lessons Learned

Through project deployment, PG&E discovered best practices that it plans to use on future battery energy storage facilities. For example, with a utility project such as this, significant effort goes into the planning, design and construction of the energy storage facility. This level of effort is relatively fixed and does not scale linearly with project size. As such, from an efficiency perspective, it makes sense to build facilities larger when addressing the challenges of obtaining land, designing and procuring major equipment, and mobilizing labor.

For example, it doesn’t require a significant amount of additional effort to add more megawatt-hours of Powerpacks, just as SCE has done at the recently installed Mira Loma energy storage facility. SCE’s 20-MW/80-MWh facility is 40 times the size of PG&E’s first lithium-ion energy storage facility, and the facility was deployed in just over six months, proving that it’s possible to build larger-scale energy storage facilities quickly.

Also, from a design perspective, it is crucial for utilities to determine early on which internal organization “owns” the energy storage resources. Utilities typically have distribution, transmission and power generation departments, and energy storage doesn’t neatly fit into any existing category. When PG&E first started building its lithium-ion storage facility, it was uncertain whether the utility would refer to energy storage as a substation asset, a power generation asset or something else entirely. Deciding between the options carried a lot of weight in terms of who would internally serve on the design team, who would be responsible for maintaining the facility and who would ultimately be responsible for ongoing facility asset management obligations. A key learning from this project is that when utilities implement new distributed energy resources such as energy storage, it is pivotal to reach alignment with internal asset owners early on in the project implementation process.

Managing the Facility

PG&E ultimately considers the lithium-ion batteries as substation assets, and as such, it manages them like other complex substation equipment such as static VAR compensators.

The facility is designed in such a way that the substation field technicians are capable of handling most issues that arise on site. To make its crews feel more comfortable with the new technology, PG&E looked for opportunities to design the balance of plant equipment such as switches, relays, breakers and transformers in a way that met the unique needs of the energy storage system while maintaining key ruggedized features seen in a traditional utility substation environment. The utility also is working on training its technicians to maintain, troubleshoot and operate the equipment within the energy storage facility.

Looking Forward

As a part of the EPIC-funded research, development and demonstration program, PG&E implemented a sister project in tandem with EPIC 1.02: EPIC 1.01 – Energy Storage for Market Operations. PG&E already owns and operates two other large-scale energy storage facilities: the 2-MW Vaca-Dixon battery in Vacaville, California, and the 4-MW Yerba Buena battery in San Jose. Both facilities are sodium-sulfur BESSs. EPIC project 1.01 deployed an automated dispatch system that enabled the Vaca-Dixon BESS to be the first CAISO market participating BESS in California. This automated dispatch platform was also used to bring the Yerba Buena BESS into the market. The BESS proved quite capable at following the California Independent System Operator’s frequency regulation and energy signals over the course of the project, and this same platform can easily be implemented for future projects. PG&E’s learnings and market participation observations are well documented in the publicly available final report.

From a project valuation perspective, energy storage is often most cost effective when owners can combine multiple value streams. Looking forward, PG&E plans to bring the functionalities tested in EPIC 1.01 and EPIC 1.02 together in a single energy storage project. In this case, PG&E is investigating combining wholesale market revenues and transmission and distribution grid services such as distribution deferral in a single project. This next step in the energy storage evolution at PG&E is the Llagas energy storage facility, which was solicited for in PG&E’s 2016 Energy Storage Request for Offer (RFO). This 10-MW to 20-MW energy storage project is proposed to feature both distribution deferral functionality, like Browns Valley, plus market participation capabilities, like Vaca-Dixon and Yerba Buena. Bids were due for the RFO in January, and PG&E will decide whether or not to move forward with the project based on project valuation and subsequent contract negotiations by fall 2017. ♦

Mike Della Penna is a principal within PG&E’s Transmission Project Development department and has supported the implementation of all three of PG&E’s utility-operated energy storage resources.

Jason Pretzlaf is a senior consulting mechanical engineer within PG&E’s Applied Technology Services department and has supported the implementation of all three of PG&E’s utility-operated energy storage resources.

About the Author

Mike Della Penna

Principal

Mike Della Penna is a principal within PG&E’s Transmission Project Development department and has supported the implementation of all three of PG&E’s utility-operated energy storage resources.

Jason Pretzlaf

Senior Consulting Mechanical Engineer

Jason Pretzlaf is a senior consulting mechanical engineer within PG&E’s Applied Technology Services department and has supported the implementation of all three of PG&E’s utility-operated energy storage resources.