Less than a year after PPL Electric Utilities completed its smart grid pilot project in the Harrisburg, Pennsylvania, U.S., area, customers in counties around Pennsylvania’s capital city are already experiencing fewer power interruptions and shorter average-outage durations.

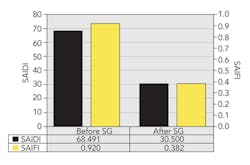

By measuring the performance of the circuits in the pilot area for 12 months ending in September 2013 and comparing it to the same circuits before the smart grid program, PPL Electric has seen a 58% drop in the average number of interruptions customers experience in a year and a 55% drop in the average number of minutes customers are without service overall.

To be fair, the weather in the period 12 months prior to the smart grid implementation was generally worse than in the 12-month period through September 2013. So, it is expected that the long-term improvement may be somewhat less than the current rate as the effects of weather normalize over time. Still, PPL Electric’s expected improvement in reliability over the next five years is projected to be 25% through the deployment of distribution automation. This improvement projection is based on reviewing three-phase distribution circuits only with major events excluded (for example, hurricanes and ice storms).

Overall Project Scope

The three-year US$38 million project, supported by an American Reinvestment and Recovery Act (ARRA) federal stimulus grant, involved the installation of close to 300 automated devices along 50 local distribution circuits serving about 63,000 customers. It also included upgrades to 10 area electric substations across 150 sq miles (388 sq km) and the development of a dedicated, secure communications system. The reliability improvement was noted on the performance of the newly automated circuits compared with nonautomated circuits in the region.

PPL Electric is encouraged by the early success of the smart grid in the Harrisburg area. Future plans include targeting vulnerable areas of the distribution system and reduce the number of interruptions that customers experience. As a result, PPL Electric is implementing a stronger, more modern distribution system to better serve its customers for years to come.

Distribution Management System

Importantly, the project included the implementation of a new distribution management system (DMS) provided by Alstom Grid, which will serve as the brain of the modernized delivery system and help the utility to manage situational awareness more effectively. With this technology, the inherent fault location, isolation and service restoration (FLISR) functionality will apply alerts from the smart devices in the field and advise system operators to remotely reroute power flow to quickly restore as many customers as possible, thereby minimizing customer outages.

Additionally, the system will have the capability to reconfigure the network automatically to isolate faults and restore customer load. By applying near-real-time electronically based distribution facilities information, the DMS will provide PPL Electric’s system operators with much greater awareness of how the system is operating in real time and enable the delivery system to recognize and instantly respond to problems. Presently, a basic supervisory control and data acquisition (SCADA) service is in place, with advanced applications of FLISR and distribution network analysis functionality to be implemented by mid-2014.

The new centralized DMS also is expected to aid system planners with more detailed information about electric usage and load on different utility equipment to better plan reliability improvements and prioritize future investments.

By the end of 2013, 25 of PPL Electric’s substations will have smart grid circuits. To enable automation, PPL Electric is using Cooper Power Systems and G&W Electric vacuum reclosers and Cleveland/Price motorized gang-operated air-break switches on its three-phase circuits coupled to communications devices. The utility also is investigating the use of S&C Electric IntelliRupter devices.

During the ARRA project, PPL Electric used WiMAX as one communications medium to transmit device status and data to the DMS, but it did not deliver the expected level of service. As a result of the lessons learned from the use of this technology, PPL Electric decided to use the public cellular network for communication of telemetry from the devices. To date, cellular communications is providing the required level of service from a latency and data perspective.

How It Works

In the event of a local interruption such as a tree falling on a power line, the smart grid sensors will detect the fault, send the information to the DMS, and then logically configure the affected distribution system to automatically provide energy from another circuit serving the area. It will happen very fast so the majority of customers only experience a momentary interruption.

For example, new vacuum circuit reclosers will be remotely controlled by computer to automatically identify a more detailed location of the damage and reroute power, which will save time and free up crews to perform repairs. Presently, this information is provided to PPL Electric’s system operators through the basic SCADA system, which enables them to remotely control devices to isolate faults and restore affected customers. In either situation, customers often can be back on-line within minutes. By comparison, it might take a field crew an hour or more to patrol the line, identify the problem and reroute power to another circuit before fixing the line.

Distribution Automation Expansion

In May 2013, PPL Electric moved into the Pocono Mountain region of northeastern Pennsylvania to begin its second phase of the smart grid project. The $10 million project, involving more than 200 smart grid equipment installations, will be completed by the end of 2013 and will improve the reliability of electric service to 70,000 Monroe County customers starting in 2014.

Monroe County was targeted for phase two because it is an area where automation would have the most benefits in terms of improving reliability for customers. Historically, customers in the Pocono region have experienced more outages of longer duration than the average PPL Electric customer. This is partly because of the wooded and mountainous terrain in the region.

After Monroe County, the smart grid technology will be implemented next year in the southern end of PPL Electric’s service territory and later to targeted circuits across the utility’s territory that require improvements in reliability. Overall, PPL Electric provides electric-delivery services to about 1.4 million customers across 10,000 sq miles (25,900 sq km) in 29 counties in central and eastern Pennsylvania. This does not include the more than 1,400 existing remote controllable devices on the distribution system, such as reclosers and motorized gang-operated switches in the utility’s service territory, which also are becoming part of the smart grid.

PPL Electric’s goal is to isolate customers to approximately 500 between smart grid devices and equip nearly 100% of the distribution system with smart grid technology by the end of this decade.

PPL Electric also plans to add remote monitoring and control on all of its distribution capacitors over the next few years. This will help to ensure all capacitors are operating properly and will reduce maintenance costs. The monitoring will provide telemetered data such as voltage and neutral current into the DMS to aid load-flow studies and understand the health of a device.

The automation strategy is estimated at more than $100 million, part of PPL Electric’s $3.8 billion investment over five years to upgrade its transmission and distribution systems. It is all part of the utility’s ongoing, long-term commitment to replace aging infrastructure and modernize its systems, improve operations and strengthen reliability for customers.

Reliability Effects

Smart grid technology is expected to have a significant effect on SAIFI, one of PPL Electric’s key customer satisfaction indicators. In terms of customer satisfaction, improving SAIFI is one of the biggest levers the utility can pull. Its investment in smart grid technology is game-changing for its reliability.

Additionally, PPL Electric’s five-year business plan includes targeting the installation of the technology on the worst-performing circuits to improve reliability in specific problematic areas. By targeting poor-performing circuits, the utility is ensuring reliability investments will have the largest impact possible. The goal is to reduce the number of customers who experience sustained outages and provide operations with enhanced situational awareness that can reduce outage durations. With improved reliability from projects such as distribution automation, PPL Electric hopes to better meet the expectations of its customers

With the addition of a DMS, the utility will have the situational awareness required by its system operators to more efficiently operate and troubleshoot the distribution system. It also enables the following benefits to PPL Electric’s operations:

- Provide real-time visualization of the distribution automation device status

- Maintain the distribution model on a daily basis to give the latest updates to system operators that are critical in showing the connectivity and sectionalizing that enable accurate FLISR capability

- Ability to implement power-flow studies with real-time information from the distribution automation devices as well as the ability to use advanced metering infrastructure hourly consumption data, which will result in more accurate load-flow calculations

- More accurately identify and isolate faults to aid quicker restoration of customers

- Ensure voltage-control devices are operating as expected and provide more visibility to voltage conditions on the circuits.

Steve Gelatko ([email protected]) is the senior manager of distribution asset planning for PPL Electric Utilities, responsible for system reliability, distribution capacity planning, distribution maintenance, research and development, and optimization of distribution investments. Gelatko created PPL Electric Utilities’ vision of smart grid development and subsequently led the team that created the company’s American Reinvestment and Recovery Act smart grid grant application.

Mike Godorov ([email protected]) is a senior project manager at PPL Electric Utilities and is leading efforts to implement a distribution management system. His previous experience includes providing project and Department of Energy compliance lead efforts on the Harrisburg smart grid project. Prior to the smart grid project, he led their Advanced Metering & Data Management Operations and helped establish PPL Electric Utilities’ smart meter plan.

Bill Keller ([email protected]) is a supervising engineer in PPL Electric Utilities’ Distribution Planning Group and leads the company’s smart grid initiative. His team determines the locations of new smart grid devices. Keller is responsible for the program including budgeting and scope. He has many years of experience in the electric utility industry.

Companies mentioned:

Alstom Grid | www.alstom.com

Cooper Power Systems | www.cooperindustries.com

G&W Electric | www.gwelec.com

PPL Electric Utilities | www.pplelectric.com

S&C Electric Co. | www.sandc.com