Digital technology has changed the way utilities are doing business, and Public Service Company of New Mexico (PNM) is no exception. Power electronics has been added to the utility’s infrastructure, renewable technologies are being deployed and the world of online data technology is being explored. PNM also has a long history of using offline digital technology to manage its assets and improve its workload efficiency. For instance, considerable time and planning go into constructing new substations. With more equipment becoming smarter and digital technology providing asset health monitoring, PNM has found that standardization is the key to reliability.

The utility can now meet its entire electrical substation and switching station design needs in-house. It has standardized the substation and switching station design architecture to accommodate 80% of its system substation design needs while supplying metadata for asset management systems. The standardized design also enables configurations to be customized for a substation or switching station, if necessary. PNM’s standards have evolved to accommodate options for its typical transmission line dead-end configurations and normal distribution feeder output configurations.

Having design tools to maintain and evolve with changing design needs is essential for effective asset management. At a minimum, a typical electrical station design package requires an electrical one-line diagram, a site plan, a general arrangement, section views, a conduit plan and a grounding plan, all of which generally require a great deal of human resources using traditional design methods. This is the reason why PNM now uses digital design tools to get the job done efficiently and cost effectively.

A Digital Design Tool

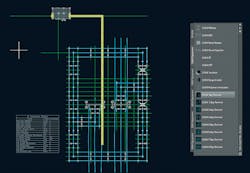

One such design tool PNM’s computer-aided design (CAD) and engineering departments use is the 3D-DASL application. Specific to the electric utility industry, this custom extension is built on AutoCAD’s 3-D capabilities. It automates the design process and saves the utility’s resources for more demanding tasks. The 3D-DASL application also automatically adds customized utility standards to the project design package for substations and switching stations. It supplies metadata and metatags for use by other data-mining platforms so important to the utility’s asset management goals. As a result, PNM’s engineers can focus more on the design functions and less on routine specifics such as equipment nameplate data, individual foundation details and structural steel drawings.

This is becoming increasingly more important as utilities add asset performance systems and deal with an aging workforce retiring across the utility industry. Baby boomers are taking their experience and institutional knowledge while leaving behind a new generation of engineers with little to no mentoring to guide them. Consequently, the new generation of engineers is reinventing the wheel and not always in the most beneficial manner.

Without seasoned engineering leadership, many are trying to redevelop company standards and manage business relationships from scratch, which can negatively impact the utility’s bottom line. Unlike the days when construction projects were handled internally by veteran engineers with in-house crews, today’s new engineers have the added responsibility of working with outside engineering consultants and subcontractors. They find themselves managing projects, approving designs, supervising the implementation of standards and administering project schedules without the safety net that a mentor provides. This is one of the most valuable aspects of 3D-DASL.

By not directly integrating 3D-DASL with an asset management system, the application can be upgraded as newer versions of AutoCAD are released. This provides PNM the opportunity to take advantage of the latest enhancements within the AutoCAD application. Another benefit of upgrading 3D-DASL is that it does not affect the asset management system and can be maintained with the latest version.

More Than Drafting

Managing design standards, tracking asset inventories and monitoring project schedules become daunting tasks that can easily get out of control between engineering consulting firms and the utility. Each outside entity brings their own level of expertise, standards and experience, which sometimes conflicts with the utility’s standards and goals. Also, critical asset management metadata can be lost if nonstandard processes are used. This can result in costly after-project labor that has to be expended to enter data missed, which can delay new projects.

An integral part of PNM’s design process, 3D-DASL brings continuity to infrastructure additions and reduces enormous data files to manageable proportions. This technique regulates the design process, rather than letting consultants perform their own custom designs based on their preferences, which can conflict with the utility’s requirements. It also provides virtual mentoring guidance to new engineers by providing direction on the design process. The 3D-DASL application offers approved substation configuration options for engineering consultants as well as new PNM personnel, while still maintaining the utility’s standards in a nonconfrontational routine.

PNM has used 3D-DASL over the years to shorten its substation and switching station design time process, reduce unnecessary CAD changes while maintaining station designs, aid with asset management and drafting standards. Because of human nature, each CAD operator and engineer has different skill levels and ideas on how a substation or switching station should be laid out, as do engineering consulting firms. Time is lost because each party changes things to meet their preferences, plus some changes seriously impact data formats required for the asset performance strategy being integrated into the industry’s asset management schemes.

When an individual or a consultant does not follow the established procedures, this has an enterprisewide impact. How can a utility ensure its new workforce has the same knowledge and uses the same criteria? How can a utility ensure everyone understands its standards as trained people leave the organization? How can a utility maintain metadata and metatags required by data-mining software? The 3D-DASL application answers these questions for PNM by implementing the utility’s standards and designs, providing a jump start for each project.

PNM’s primary design types include every piece of equipment needed for a given substation or switching station of the project, such as transformers, switchgear, transmission termination, connectors, bus bars and station steel.

Standards Defined

It took a great deal of work across departments within the PNM enterprise to move to standardization. It was determined the resulting standard distribution substation layouts could be normalized into single-unit and two-unit designs. For switching stations (115 kV and 345 kV), a single-bay to eight-bay layout was determined to be PNM’s standardized approach. Further standardization by the PNM distribution planning department adjusted the size of distribution substation’s transformers to three specific top ratings, 16 MVA, 22 MVA and 33 MVA.

Standardization continued and PNM reduced the station design to three specific types of switchgear, two feeders, three feeders and four feeders. A designer also had a choice of whether to add a main breaker. A side benefit of standardizing specific transformer and switchgear ratings was that while there was a reduction in spare inventory requirements, there was an increase is the possibility of having a spare on hand.

The 3D-DASL application provides common standards and common equipment modules for 115 kV, 138 kV, 230 kV and 345 kV, but the engineer always has the capability of substituting a nonstandard piece of equipment, if necessary. With standardized substations and switching stations, 3D-DASL provides automated designs that accommodate 80% of all PNM’s design requirements. The application also provides standard design modules with routines that enable the engineer to add individual pieces of equipment to the substation, such as dead-end structures, bus bar layout, ground grid, conduit, and fence and wall layouts.

Over the years, PNM’s engineers have had to add to existing facilities that were built using hard-copy construction drawings done by hand. As a result, 3D-DASL was revised to provide the functionality to work with existing facility drawings, whether they are in raster (scanned image) or vector format. This process is not as fast as the standardized, menu-driven new construction features, but it beats using conventional CAD techniques to redraw the old-school substation drawings.

With all these features, 3D-DASL also is structured to help maintain utility standards while, at the same time, reducing the design time and minimizing incorrect design exposures. It provides the less-experienced designer or engineer with common equipment standards for distribution substation and switching station layouts. Because of these built-in attributes, less experience and less training is required on the people side. A major design benefit of this digital tool for PNM has been a reduction in engineering design time from months to hours.

Benefits of 3D-DASL

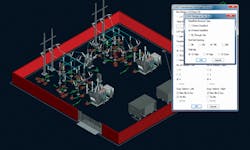

The 3D-DASL application offers another feature proven to bring added value to PNM: 3-D modeling. The creation of a 3-D model enables the station design drawings to be imported into visualization programs, such as Autodesk 3ds Max, SketchUp or AccuRender. The results are photorealistic images and animations useful for siting studies and permitting.

The creation of a 3-D model also enables an engineer to check clearance issues and eliminate potential electrical hazards without danger to any personnel. The 3D-DASL application does not rely on engineers, technicians or draftsmen having 3-D CAD knowledge or training. It provides this foundation and enables a highly trained workforce to develop in a nonthreatening environment.

Digital design tools such as 3D-DASL can be instrumental in overcoming the inertia of resisting the formation of a managed business relationship between utilities and equipment manufacturers (for example, transformers and switchgear). They also can be powerful bridges for the sharing of information and data when integrated into end-to-end asset management schemes. PNM already has tied 3D-DASL’s one-line system diagram drawings and station mechanical drawings to its geographic information system programs.

The utility’s next step will be to add 3-D models to those geographic information system programs, providing engineering with one point of access for station location, facility management and asset location. In today’s complicated smart grid, digital tools such as 3D-DASL are making it possible for the workforce to keep up with the demands of the transmission and distribution system while adapting to the increasing demands for more cost-effective and reliable designs. ♦

Gathen Garcia directs the drafting and geographic information systems (DGIS) group for Public Service Company of New Mexico. The DGIS group was established to develop, manage and communicate an array of geographic data and visual information important to the success of PNM Resources as a leading energy provider. Under Garcia’s leadership, DGIS is structured into three broad groups: computer-aided design (CAD), GIS and information visualization (InfoVis). The small but versatile CAD and GIS staff complement each other to provide unique and powerful data management, presentation tools, design tools and services to a broad range of clients ranging from the technical to the nontechnical, from engineers to the executive suite.

Check out the November 2017 issue for more articles, news and commentary.