Aging equipment is part of the nature of the electric industry. Utilities plan for 40 years or more of service from major equipment. Various maintenance methods and approaches have been developed to stretch asset lifetime; however, those approaches often do not consider fully the impacts on system performance. While replacement could be postponed, service to customers might degrade, potentially resulting in frequent outages, poor power quality and reduced reliability of transmission system facilities over time.

At ITC Holdings Corp., transmission is planned in compliance with the North American Electric Reliability Corporation (NERC) transmission planning (TPL) standards, meaning outages of transmission equipment do not always result in outages to end-use customers. Nonetheless, transmission equipment continues to age. Eventually, this aging equipment reaches its design capacity limits and becomes difficult to maintain.

Older Transmission Assets

In the eight years ITC has owned and operated Michigan Electric Transmission Co., LLC (METC), overall system performance has improved steadily because of targeted system enhancements and focused maintenance. However, portions of the METC system are old, with some transmission lines in rural areas approaching 80 years in service. For these assets, ITC became concerned increasing failure rates would degrade system performance noticeably. To address this concern, ITC engaged Quanta Technology to assess the METC transmission system and provide recommendations related to asset renewal.

The focus of the assessment was on transmission lines only, with an evaluation of the major components that make up these transmission lines (that is, structures, foundations, cross arms, conductors and insulators). The objective of the project was to define an acceptable level of system performance and then develop an asset renewal program ITC could use to maintain this acceptable level of performance.

Sufficient data was collected to make a meaningful evaluation, including detailed asset information, maintenance records, inspection findings and operational history. ITC collected this information and improved data organization. These improvements included storing data in software and databases such as standardized spreadsheet data sets, a separate asset database, PDFs and outage databases.

Results-Oriented Asset Management

ITC needed a tool to predict system reliability related to the performance of these assets to understand better the impacts to the system as these assets aged. The maintenance history of the METC system was detailed sufficiently to identify whether operational issues and maintenance activities were oriented toward the structure, foundation, conductor, insulators or crossarms associated with a given structure. The challenge was to apply this information in such a way as to understand how performance had degraded over time and, if possible, use it to gain insights into future performance.

A key consideration for reliability in the METC system was the number of steel structures undersized by current standards, raising concerns about their long-term performance. Because the number of these structures is significant, ITC felt maintenance, or partial or complete rebuilds, needed to be planned for immediately and undertaken in the near future, so the volume of work necessary to renew the assets could be managed effectively while maintaining system reliability.

Quanta Technology had performed similar projects that used concepts from the field of reliability engineering. In this field, reliability is defined as the ability of a system or component to function under stated conditions for a specific period of time. Quanta Technology expanded these concepts into a service offering called Results-Oriented Asset Management (QT-ROAM). This provided a method to decompose the performance of a circuit into individual components, develop probability curves of failure as those components age and then recombine the probabilities into an overall failure curve for the given circuit. Taking this approach is feasible if sufficient historical performance and maintenance data are available. It can provide insights into future performance.

Rigorous Approach to O&M

Such an approach is a logical extension of ITC’s approach to operations and maintenance (O&M). The processes are open to stakeholder and regulatory scrutiny, and allow for stakeholder participation through the regional transmission organization planning process, in this case, the processes of the Midcontinent Independent System Operator (MISO). The method provides a rigorous approach to the issue of performance as the system ages. Components of the approach are as follows:

- Review, categorize and organize the historical outage records, inspection records and maintenance events

- Identify relevant metrics to measure reliability and quantify acceptable levels of asset performance

- Review outage histories and identify the worst-performing circuits on the METC system

- Analyze historical outages, inspection reports, and maintenance data, records and guidelines for the worst performers

- Apply the QT-ROAM asset renewal program to provide a forward, statistical model of asset maintenance activities to forecast future performance of these circuits

- Correlate the changing probability of failure with the age of the circuit to create an operational forecast sufficient to identify candidates for rebuild, maintenance or further inspection.

Defining the objectives and setting up the data sets took the bulk of the project time, but it was critical to ensure an analysis was performed that took advantage of all available data and the results aligned with ITC’s system performance expectations.

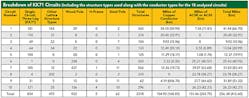

Prior to the analysis, concerns were focused on very old, light-duty steel towers in rural portions of the system. This structure type, the KK71, was a key focus of the analysis. However, early examination revealed the worst-performing circuits on the METC system also included a mix of wood poles and one type of medium-duty steel tower as well as the KK71s.

The project team developed a failure rate for each of these circuits using specific data that described the performance of structures and associated equipment within the circuit (structures, foundations, crossarms, conductors and insulators). Data surrounding past operational history was layered on to find a correlation between outages and failures to forecast performance. This forecast then provided a basis to evaluate rebuild, maintenance and repair options as well as to develop recommendations.

Performance Metrics

From a reliability engineering standpoint, reliability describes the ability of a system or component to function under stated conditions for a specific period of time. The challenge was to convert this definition of reliability into a performance metric relevant to the operation of the METC system.

A variety of metrics could be envisioned for use in evaluating and comparing transmission system reliability. NERC developed the transmission availability data system (TADS) metrics to quantify the performance of utilities. There are 11 metrics in the set. Of these, the following were selected for the METC system reliability analysis:

- Element total automatic outage frequency (TOF)

- Element sustained outage frequency (SOF)

- Element momentary outage frequency (MOF).

These data sets helped to characterize a wide range of trends, including increasing, constant and decreasing failure rates. ITC concluded three or more outages per year — either momentary or sustained — would be an appropriate level to trigger action.

Circuit Selection and Forecasting

The reliability analysis used the METC outage history to identify poor-performing circuits. This approach focused the analysis since the objective was to identify asset renewal efforts intended to maintain or enhance reliability. Of the 44 138-kV circuits analyzed, the 30 worst-performing circuits were identified and became the focus of the analysis. For 345-kV circuits, circuits that averaged one or more outages per year were selected. Using this approach, 17 345-kV circuits were identified for detailed analysis.

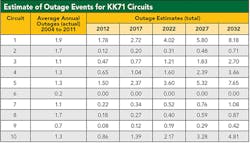

Circuits with the KK71 structure type can be used to illustrate the process. To assess future operating performance, a correlation was made between the forced outage history and maintenance history. This correlation was applied to the maintenance forecast to assess changes in operating performance over time.

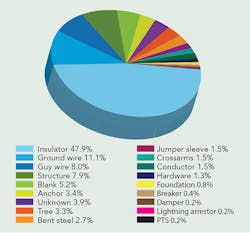

The operational and maintenance reviews identified failure causes by equipment type — critical data for use in forecasting issues. The pie chart shows the causes of outages on KK71 circuits. This distribution of maintenance events was useful for developing insights into how maintenance activities could be conducted in the future. By making the assumption the historical distribution of maintenance actions was indicative of future maintenance events, maintenance events by category could be forecasted.

Many of the worst-performing circuits relied heavily on KK71 structures. Therefore, all circuits using the KK71 structures were analyzed. However, these 10 circuits used other structures in addition to the KK71. They typically included a combination of KK71, other older lattice structures and wood poles. To perform the analysis, the maintenance and operational history of each structure type was analyzed, providing the foundation for a forecast of maintenance activity into the future as the structures within the structure type aged.

Since the composition of each line was known, maintenance forecasts for each structure were added up to create an aggregate maintenance forecast for the circuit. This gave ITC improved insights into expected maintenance activities as the circuit aged. Using the historical pattern of maintenance for each structure, ITC was able to develop a maintenance forecast by category (for example, structure, foundation, insulator and conductor) to give maintenance personnel a sense of how equipment failures might occur and what type of O&M spend might be looming if no action were taken.

The next step in the analysis was to understand how this maintenance forecast would provide insights into future operational performance. This started with a review of the maintenance and outage histories to develop a correlation between operational events (such as momentary trip and forced outage) and maintenance events. As expected, there was a higher correlation for older circuits. Note that high maintenance counts implied a rebuild had occurred and, indeed, this was the case. Low correlation factors reflected improved performance after the maintenance for circuits 2 and 6. Circuit 9 also had been rebuilt.

Additional analysis was performed to break this down further into sustained and momentary estimates. Based on the operations forecasts, the performance metrics were applied, revealing whether a circuit was performing adequately, or repair or replacement might be warranted. By creating an outage forecast, this method can provide insights into outage performance on a circuit-by-circuit basis, allowing the calculation of element availability metrics related to system performance. The analysis results allowed the worst-case circuit assessment to indicate when the forecast exceeded three outages per year.

Final Project Recommendations

Compiling all of the data together resulted in the following project recommendations, aimed at keeping METC system performance at acceptable levels:

- Six 138-kV lines were targeted for partial rebuild (insulator replacement, tower painting, wood pole replacement and/or copper conductor replacement)

- Three 138-kV lines were selected for a complete rebuild to start in 2015

- Six 345-kV lines were identified for additional inspection.

Success Factors

Several factors contributed to the success of this analysis. First and foremost was the ability to articulate the objective and translate it into a quantitative metric (that is, events per year) used to guide maintenance decisions. Success also depended on having detailed asset records, a maintenance database (including unique IDs and history for each piece of equipment) and accessible outage histories.

This case study illustrates that to improve the reliability of the transmission system, it is important to perform an analysis of aging transmission assets properly to gain insights into future operational performance of those assets. Using appropriate metrics, these insights can be used to develop a richer understanding of the needs of the system and to establish a stronger justification for watch, repair or replace decisions.

Janice Yen ([email protected]) is a senior engineer in operational planning at ITC Holdings Corp. Her areas of expertise include operational planning and long-term transmission system planning. She supports real-time operations, coordinates planned facility outages with interconnected entities and develops mitigation plans to ensure reliable operation of transmission systems. Other capabilities include capital project development, reliability assessments, transmission system performance and reactive power compensation. Yen holds a BSEE degree from Michigan State University and is a member of the Midcontinent Independent System Operator transmission-owner low-voltage task team.

Donald J. Morrow ([email protected]), is senior vice president of corporate strategy at Quanta Technology, where he provides consulting services to transmission clients. He founded the transmission consulting practice at Quanta Technology and oversaw its growth to become the largest team within the company. Areas of expertise include system planning, control area operations, transmission operations, operator training and energy management systems. Morrow holds BSEE and MBA degrees from the University of Wisconsin. He is a member of IEEE and a registered professional engineer.

Mentioned in this article:

METC | www.itc-holdings.com/itc-michigan.html

MISO | www.misoenergy.org

NERC | www.nerc.com

Quanta Technology | www.quanta-technology.com