The distribution grid is quickly evolving into a real-time system that dynamically changes instantaneously. As connected loads continuously vary, component failures necessitate changes in the interconnected system of feeders and substations. These system changes typically happen extremely fast, such as when a failed piece of equipment is isolated by the protection systems. When these high-speed dynamic changes take place, a true smart grid control system must react in symphony with these changes to provide consumers with alternative power sources.

Conventional supervisory control and data acquisition (SCADA) systems are historically more static in nature and not necessarily able to keep up with the increased need for real-time reactions in the power grid. Measured field status information is slowly communicated up to an operations center, and the measured information could take minutes before it reaches the operator screens. Because of this delay, true real-time synchronous operations cannot be accomplished. Operators are forced to wait for stable system conditions or run possible simulated sequences before actual switching sequences can be executed to provide alternative power to consumers.

Advances in intelligent grid technologies promise to close this gap by providing faster-acting or real-time systems, and utilities already are making vast improvements to achieve success. One example of a utility making these advances is Wake Electric Cooperative.

Faster, Faster

To date, the board of Wake Electric has approved the deployment of advanced metering infrastructure (AMI), an outage management system (OMS) and, most recently, a real-time distribution feeder automation project. The cooperative is continuously looking to implement and test new technologies that could improve operations. These systems were once considered “nice to have,” but the investments are now mission critical for Wake Electric’s grid to become truly smart.

Established in 1940, Wake Electric is trusted to serve more than 37,000 members in parts of seven counties of North Carolina, U.S. It operates more than 3,100 miles (4,989 km) of transmission and distribution lines, and, for a cooperative, its density is relatively high with an estimated 12 meters per mile. To optimize its network infrastructure decisions, Wake Electric chose the services of the Siemens Smart Grid. Siemens first communications modeling and simulations using its Smart Grid Communications Assessment Tool (SG-CAT) to determine where Wake Electric would benefit most in terms of expanding its communications infrastructure.

Build It Once

Cooperatives typically look at one application at a time, resulting in a hodgepodge of communications networking. Wake Electric’s approach was to make its network future-proof and to build it once, not twice. The communications system had to support the utility’s need to optimize the operation of its electricity distribution system and accommodate the trend toward automation. It sought to deploy smart metering and SCADA systems; feeder automation with fault location, isolation and service restoration (FLISR) capabilities; distribution automation; and other opportunities as they become available.

After the communications study was conducted, results showed a 3.65-GHz WiMAX system would be the most suitable system for Wake Electric to invest in. This WiMAX communications system would provide numerous benefits:

- Replacement of less reliable, shared public network system’s substation backhaul

- Metering backhaul

- Integration of new automation systems with SCADA

- Support for real-time automation systems.

Once the study was complete, Siemens identified another way to help Wake Electric by implementing a new locally developed Siemens distribution feeder automation system (SDFA) as part of a pilot project. Just down the road from Wake Electric in Wendell, North Carolina, Siemens was developing, testing and implementing distribution feeder automation, a true real-time FLISR system.

The system is extremely unique in that it can, in the blink of an eye, locate and isolate a faulted feeder line section and reconfigure a feeder system to provide all other line sections with alternative power. The local Siemens team developed a new protection method that simplified protection of automated distribution feeders.

But the FLISR system required a robust and reliable communications system to perform at high speed; the WiMAX solution selected by Wake Electric was well suited to the task. After putting in place the necessary technology to support feeder applications, Wake Electric agreed to implement a pilot project using the SDFA-FLISR system.

From Concept to Implementation

The first challenge of the implementation of the FLISR system was deploying the WiMAX system. Wake Electric had to find tower assets for deployment of the WiMAX base stations as WiMAX is a point-to-multipoint system. The base stations communicate from a central location to multiple field subscriber radios and must be mounted as high as possible to maximize reach to field subscriber units. Increasing the height of the base stations directly results in less required height for the field radios.

As luck would have it, one of Wake Electric’s commercial customers is local radio station WCPE 89.7. The station owned a tower that was more than 1,000 ft (300 m) tall, making it an ideal location for the deployment of the WiMAX base stations. However, WCPE was fed from a nonautomated feeder and to provide alternative power to WCPE could take long periods of time. WCPE had approached Wake Electric in the past about providing alternative power to the facility, but the cost was prohibitively high at the time.

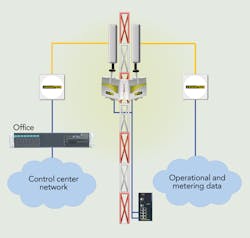

Wake Electric proposed a solution that would benefit both the station and the utility by offering to automate the feeder supplying the WCPE site as part of the FLISR pilot project. In return, WCPE would provide space on its tower for the mounting of the WiMAX base stations. WCPE agreed and four base stations were mounted at a height of 425 ft (130 m). The base stations provided 360-degree coverage reaching up to 11 miles (17 km). This coverage included a major portion of the metering points for Wake Electric.

Coverage and Functionality

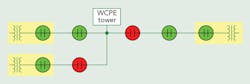

This area also includes the Wake Electric control center and 10 substations with substation backhaul possibilities. The coverage incorporates communication to all field devices that formed the new high-speed FLISR system, which supports the WCPE tower as well as a large number of consumers with alternative power. The FLISR system includes three substation power sources that are interconnected using new and existing reclosers. The system was divided into five line sections, each providing power to consumers and the WCPE tower.

The system provides source-transfer functionality to all line sections with source-transfer sequences executed within a quarter of a second and FLISR sequences executed in less than a half second. That really is faster than the proverbial “blink of an eye.” The FLISR system also introduced a new protection method that simplifies the protection of automated feeders. The system uses a jDiff protection function to locate and isolate faults on line sections, which eliminated the need for traditional complex coordinated overcurrent schemes.

In the past, automation systems were restricted to change a feeder only to a small number of topologies. This was because of the restrictions imposed by the protection system’s inability to adapt to changes made by the automation system. But this new system changes the topology to isolate any faulted line sections and then reconfigures the feeder to provide power to all line sections that are fault free. The loss of any substation power source also leads to a reconfiguration where the remaining available sources support the feeder network’s line sections and connected consumers.

The system determines, in real time, whether the power source can support the load to be connected by the closure of a recloser. The system follows a nontraditional switching technique to increase the speed of operation. For example, if a tree fell on a line section, the system would open the recloser upstream of the fault and close it immediately to test whether the fault was temporary in nature. The system would then isolate this line section and reconfigure the feeder to ensure line sections downstream from the faulted line section were connected to alternative power. Afterward, the system would perform reclose cycles on the faulted line sections only.

The reclose cycles can be performed as three- or one-pole switching depending on the type of load connected to a particular line section.

System Specifics

The SDFA-FLISR system is a decentralized system of substation-hardened devices combining protection and automation to achieve real-time automation performance. The devices communicate peer-to-peer using International Electrotechnical Commission (IEC) 61850 generic object-oriented substation event (GOOSE) messages. The WiMAX communications system selected supports the FLISR system with secure peer-to-peer communications.

The GOOSE messages are communicated over a layer-two network, but security using layer two is always questioned. The FLISR application enables GOOSE messages to ensure secure operation. The quality information contained in each of the multiple GOOSE messages is evaluated before any recloser operation can be executed and any duplicate messages will inhibit the FLISR system from executing automated sequences. The GOOSE quality information also provides a means to rapidly detect a communications link failure.

The WiMAX RuggedMAX system complements the system technologies by providing high-quality service. It enables the user to separate traffic types over the air and guarantee latency, minimum bandwidth and jitter according to application needs. This was an important feature used to separate the FLISR system’s GOOSE traffic from the backhaul traffic. Thus, the FLISR system could be guaranteed to have acceptable latency and bandwidth, enabling the real-time performance of a true smart grid system.

The WiMAX system also supports the backhaul of substation operational and AMI metering data to the utility’s control center or office. The FLISR system is decentralized but was deployed with a PC-based human-machine interface (HMI). This HMI was installed in the Wake Electric office building and provides a control interface that gathers all operational and nonoperational data. The HMI also provides a DNP3.0 interface to the SCADA system. Wake Electric then developed SCADA control screens to operate the FLISR system from the SCADA operation center.

Connection to the OMS included the integration of six new operational scenarios that could be executed as part of the FLISR sequences. Historically, the Wake Electric OMS used lockout status from substation reclosers and Sensus AMI meter alerts as triggers. The scenarios were communicated by the FLISR system as DNP3 commands to the OMS. The OMS was updated to reassign smart meters from one source to another based on the new system topology configuration.

Field Integration

If a FLISR operation sequence was executed for a temporary fault, the FLISR system would automatically restore the system back to the preferred source topology. Field integration of the WiMAX and FLISR systems proved not to be a challenge to Wake Electric’s staff. The WiMAX system required a few new skills to test and install in the field, but the teamwork between Wake Electric’s engineering and IT departments was a major success factor in the deployment.

The 7SC80 controllers of the FLISR system were integrated through plug and play into three new reclosers and three existing reclosers. For Wake Electric, the interoperability of the FLISR system was of the utmost importance. Field crews were trained to operate the reclosers using the 7SC80 HMI, which was programmed to emulate the recloser controls used by Wake Electric as a standard.

Keeping Up with Changes

The FLISR system’s operational speed installed at Wake Electric can keep up with the dynamic nature of the electrical grid and the communications system is future-proof to support other applications and services. These technologies enabled Wake Electric — as a nimble, medium-sized cooperative — to deploy a true smart grid system.

Wake Electric now plans to expand its current FLISR and WiMAX systems, proving that projects that may begin as “nice to have” can transform into significant benefits for a utility and its consumers.

Acknowledgement

Wake Electric would like to acknowledge Andre Smit, product manager for Siemens Smart Grid, and his team. Their contributions were key to the successful efforts of this feeder automation project.

Don Bowman ([email protected]) is manager of engineering for Wake Electric Cooperative. Previously, he spent 11 years at National Rural Telecommunications Cooperative as vice president of utility solutions, focusing on technologies that help electric cooperatives improve operating efficiencies.

Companies mentioned:

International Electrotechnical Commission | www.iec.ch

Sensus | http://sensus.com

Siemens | www.siemens.com

Wake Electric Cooperative | www.wemc.com